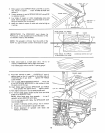

CHECKING BLADE SQUARENESS TO TABLE

I, Loosen ELEVATION LOCK by pulling KNOB forward,

2. Turn ELEVATION handwheel clockwise until blade is

as high up as it will go,

IMPORTANT: BLADE must be SQUARE (90 ° ) to

TABLE, in order to ALIGN rip fence,

3, Check for BLADE SQUARENESS .... if blade is not

square to table, adjust it at this time,,

NOTE: The combination square must be "true" - see

start of "Unpacking and Checking Contents" section on

page 6 for checking method

Refer to "BLADE TILT, OR SQUARENESS OF BLADE

TO TABLE" adjustments on page 24

MAKE SURE SQUARE

IS NOT TOUCHING

TiP OF TOOTH

TILT CLAMP KNOB

ELEVATION

HANDWHEEL

-....

TILT CRANK

ELEVATION LOCK KNOB

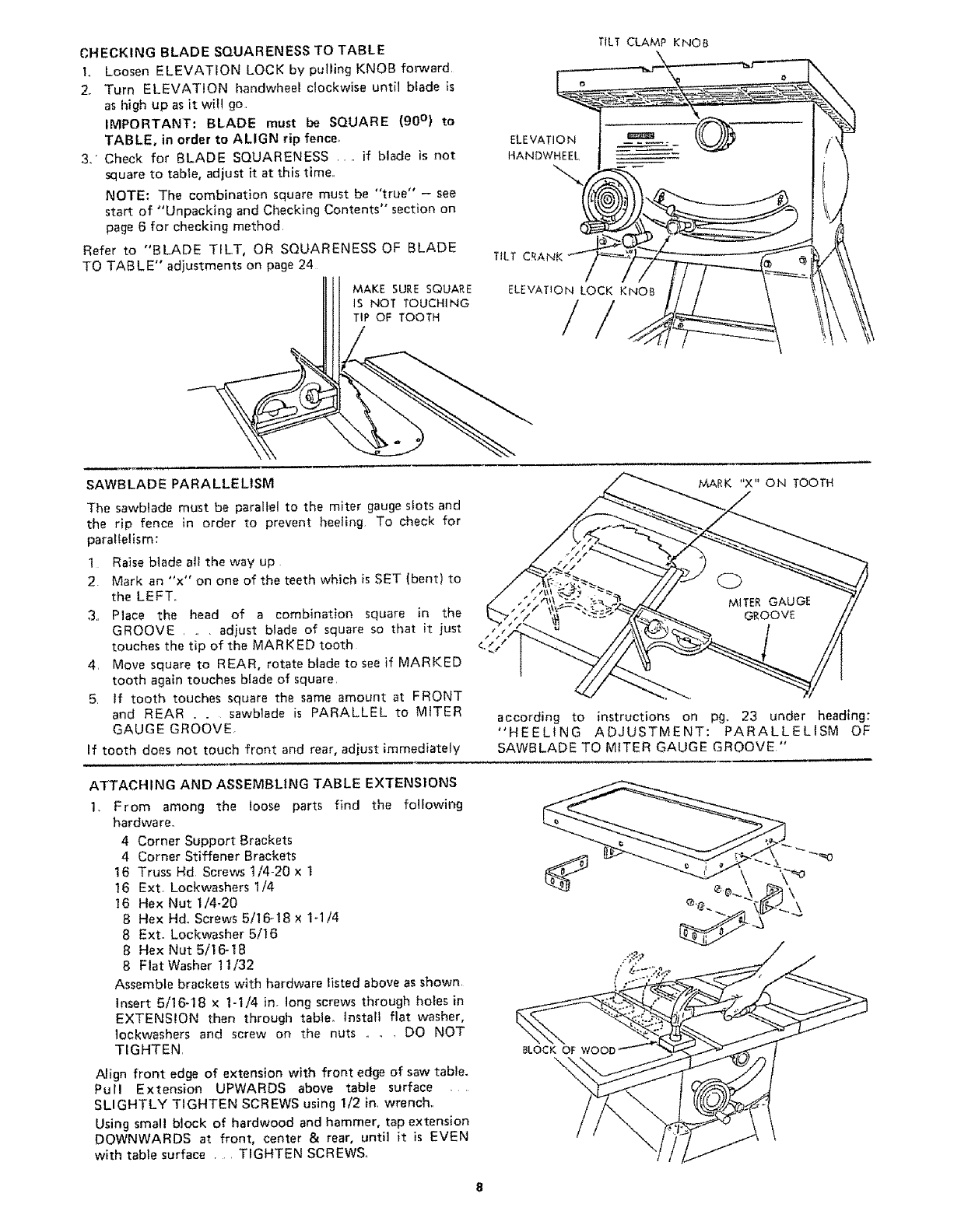

SAWBLADE PARALLELISM

The sawblade must be parallel to the miter gauge slots and

the rip fence in order to prevent heeling To check for

parallelism:

I Raise blade all the way up

2. Mark an "x" on one of the teeth which is SET (bent) to

the LEFT.

3, Place the head of a combination square in the

GROOVE .... adjust blade of square so that it just

touches the tip of the MARKED tooth

4, Move square to REAR, rotate biade to see if MARKED

tooth again touches blade of square,

5, If tooth touches square the same amount at FRONT

and REAR .... sawblade is PARALLEL to MITER

GAUGE GROOVE

If tooth does not touch front and rear, adjust immediately

MARK *'X" ON TOOTH

according to instructions on pg. 23 under heading:

"HEELING ADJUSTMENT: PARALLELISM OF

SAWBLADE TO MITER GAUGE GROOVE"

ATTACHING AND ASSEMBLING TABLE EXTENSIONS

1, From among the loose parts find the following

hardware,

4 Corner Support Brackets

4 Corner Stiffener Brackets

16 Truss Hd Screws 1/4-20 x 1

16 Ext, Lockwashers I/4

16 Hex Nut 1/4-20

B Hex Hd, Screws 5/16-18 x 1-1/4

8 Ext° Lockwasher 5/16

8 Hex Nut 5/16-18

B FlatWasher 11/32

Assemble brackets with hardware listed above as shown,

Insert 5/16-18 x t-1/4 in. long screws through holes in

EXTENSION then through table° tnstarl flat washer,

lockwashers and screw on the nuts .... DO NOT

TIGHTEN,

Align front edge of extension with front edge of saw table_

Pull Extension UPWARDS above table surface ....

SLIGHTLY TIGHTEN SCREWS using !/2 in, wrench.,

Using smal! block of hardwood and hammer, tap extension

DOWNWARDS at front, center & rear, until it is EVEN

with table surface , , TIGHTEN SCREWS.

BLOCKOF

\

/

f