_- ELEVATION HANDWHEEL ,elevates or lowers the

blade Turn clockwise to elevate .... counterclockwise

to lower,

3 ELEVATION LOCK ..... locks the blade at the desired

height. PUSH in to LOCK .... PULL out to unlock.

4 TILT CRANK , tilts the blade for bevel cutting,

Turn clockwise to tilt toward [eft .... counterclockwise

to tilt toward right,

When the blade is tilted to the LEFT as far as it will go,

it should be at 45 ° to the table and the be_el pointer

should point 45 °

NOTE: There are LIMIT STOPS inside the saw which

prevent the blade from tilting beyond 450 to the LEFT

and 90 ° to the RIGHT., (See "Adjustments" section

"Blade Tilt. or Squareness of Blade to Table")

6

TILT LOCK KNOB , locks the blade in the desired

tilt position, Turn it to the left to unlock .... to the

right to lock,

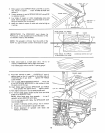

RIP FENCE , is locked in place by tightening the

lock knob To move the fence, loosen the knob and

grasp the fence with one hand at the front

Holes are provided in the rip fence for attaching a wood

facing when using the dado head, or molding head,

Select a piece of smooth straight wood approx. 3/4 in,

thick and the same size as the rip fence,

Attach it to the fence with three Round Head #t0

Wood Screws 2 in,, long, To remove the facing, loosen

the screws, slide the facing forward and pull the screws

through the round holes

ff you are making a rip type cut in material thinner

than 3/t6 in,, while the fence is positioned over the

depressed area of table extension, the facing should be

attached to the fence so that the bottom edge touches

the top surface of the extension,, In this case, the facing

must be shorter than the fence This will prevent thin

material from sliding under the rip fence

WOOD FACING

\

10 WOOD SCaEWS

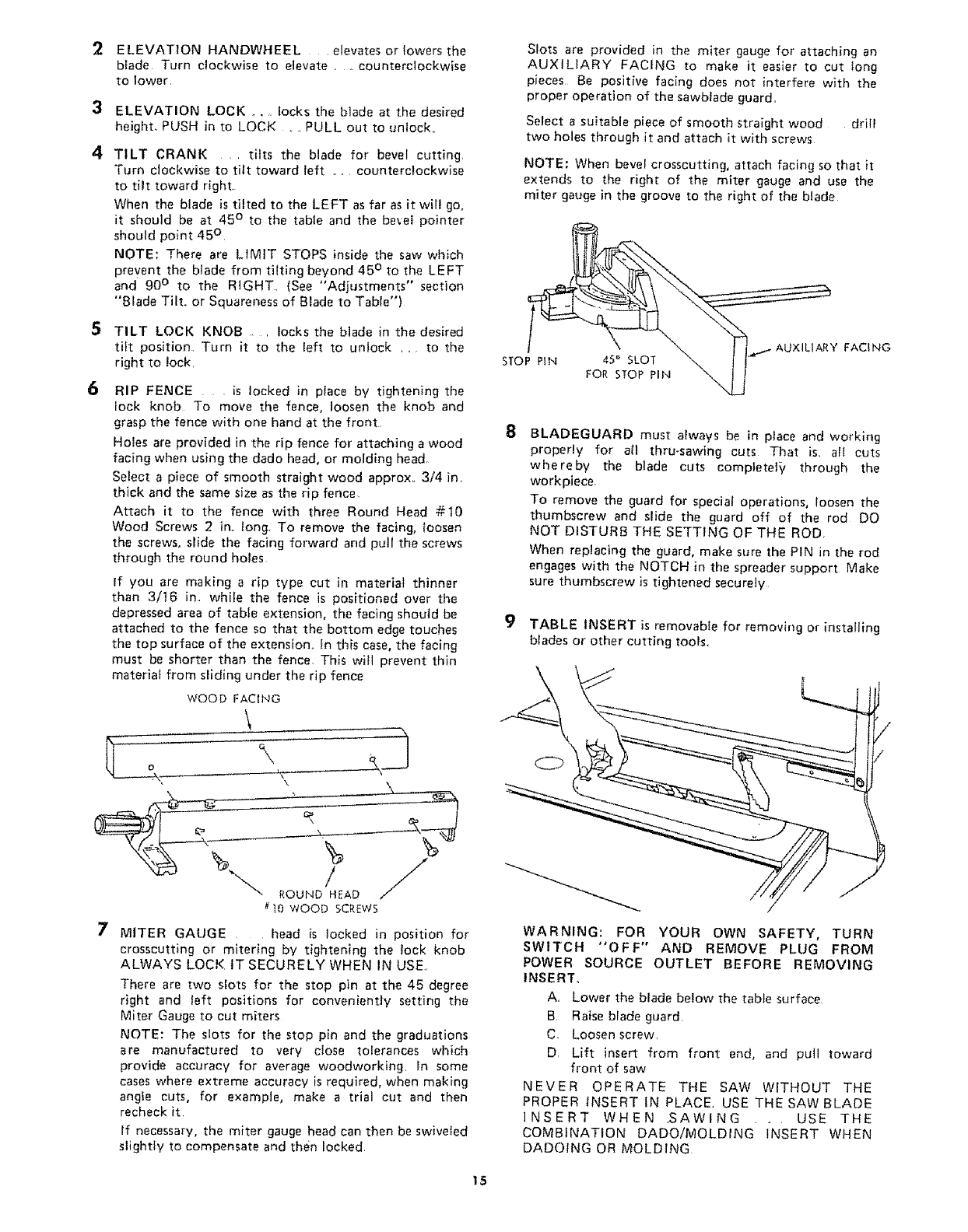

7 MITER GAUGE head is locked in position for

crosscutting or mitering by tightening the Iock knob

ALWAYS LOCK IT SECURELY WHEN IN USE,,

There are two slots for the stop pin at the 45 degree

right and left positions for conveniently setting the

Miter Gauge to cut miters

NOTE: The slots for the stop pin and the graduations

are manufactured to very close tolerances which

provide accuracy for average woodworking, In some

cases where extreme accuracy is required, when making

angle cuts, for example, make a trial cut and then

recheck it

If necessary, the miter gauge head can then be swiveled

slightly to compensate and then locked

Slots are provided in the miter gauge for attaching an

AUXILIARY FACING to make it easier to cut tong

pieces Be positive facing does not interfere with the

proper operation of the sawbtade guard,

Select a suitable piece of smooth straight wood drill

two holes through it and attach it with screws

NOTE: When bevel crosscutting, attach facing so that it

extends to the right of the miter gauge and use the

miter gauge in the groove to the right of the blade

STOP PIN 45_ SLOT

.P,N Fo %LOTp,.

BLADEGUARD must always be in place and working

properly for atl thru-sawing cuts That is. all cuts

whereby the blade cuts completelY/ through the

workpiece,

To remove the guard for special operations, loosen the

thumbscrew and slide the guard off of the rod DO

NOT DISTURB THE SETTING OF THE ROD,

When replacing the guard, make sure the PIN in the rod

engages with the NOTCH in the spreader support Make

sure thumbscrew is tightened securely

9 TABLE INSERT is removable for removing or installing

blades or other cutting tools,

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE REMOVING

INSERT,

A,r Lower the blade below the table surface

B Raise blade guard,

C, Loosen screw,

D, Lift insert from front end, and pull toward

front of saw

NEVER OPERATE THE SAW WITHOUT THE

PROPER tNSERT tN PLACE USE THE SAW BLADE

INSERT WHEN .SAWING .... USE THE

COMBINATION DADO/MOLDtNG INSERT WHEN

DADOING OR MOLDING

t5