assembly and adjustments

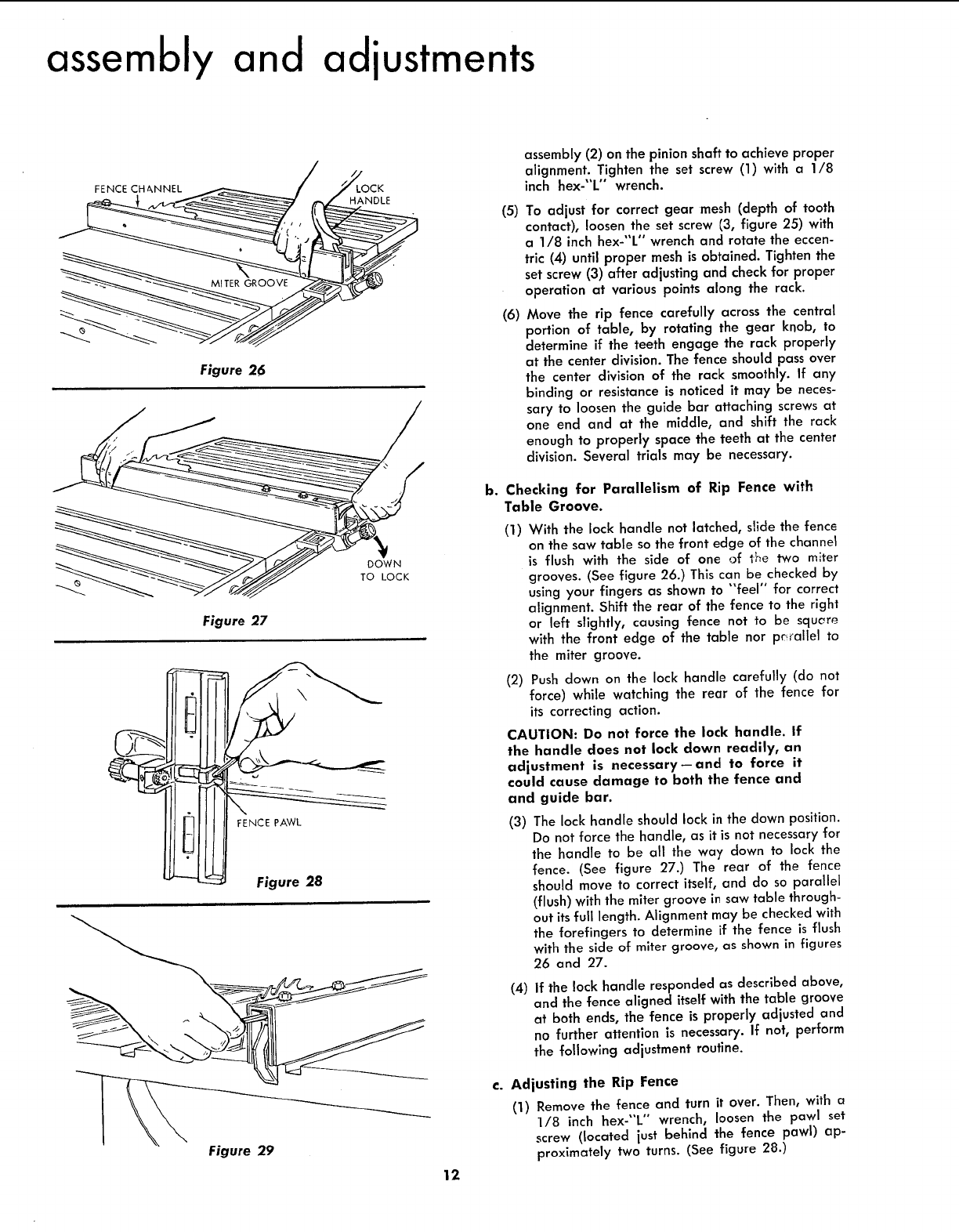

Figure 26

DOWN

TO LOCK

Figure 27

FENCE PAWL

Figure 28

Figure 29

12

(5)

(6)

assembly (2) on the pinion shaft to achieve proper

alignment. Tighten the set screw (1) with a 1/8

inch hex-"L" wrench.

To adjust for correct gear mesh (depth of tooth

contact), loosen the set screw (3, figure 25) with

a 1/8 inch hex-"L" wrench and rotate the eccen-

tric (4) until proper mesh is obtained. Tighten the

set screw (3) after adjusting and check for proper

operation at various points along the rack.

Move the rip fence carefully across the central

portion of table, by rotating the gear knob, to

determine if the teeth engage the rack properly

at the center division. The fence should pass over

the center division of the rack smoothly. If any

binding or resistance is noticed it may be neces-

sary to loosen the guide bar attaching screws at

one end and at the middle, and shift the rack

enough to properly space the teeth at the center

division. Several trials may be necessary.

b. Checking for Parallelism of Rip Fence with

Table Groove.

(1)

With the lock handle not latched, slide the fence

on the saw table sothe front edge of the channel

is flush with the side of one of the two miter

grooves. (See figure 26.) Thiscan be checked by

usingyour fingers as shown to "feel" for correct

alignment. Shift the rear of the fence to the right

or left slightly, causing fence not to be squcre

with the front edge of the table nor pr_allel to

the miter groove.

(2) Push down on the lock handle carefully (do not

force) while watching the rear of the fence for

its correcting action.

CAUTION: Do not force the lack handle. If

the handle does not lock down readily, an

adjustment is necessary-and to force it

could cause damage to both the fence and

and guide bar.

(3) The lock handle should lock in the down position.

Do not force the handle, as it is not necessary for

the handle to be all the way down to lock the

fence. (See figure 27.) The rear of the fence

should move to correct itself, and do so parallel

(flush) with the miter groove in saw table through-

out its full length. Alignment may be checked with

the forefingers to determine if the fence is flush

with the side of miter groove, as shown in figures

26 and 27.

(4)

If the lock handle responded as described above,

and the fence aligned itself with the table groove

at both ends, the fence is properly adjusted and

no further attention is necessary. If not, perform

the following adjustment routine.

€. Adjusting the Rip Fence

(1) Remove the fence and turn it over. Then, with a

1/8 inch hex-"L '° wrench, loosen the pawl set

screw (located just behind the fence pawl) ap-

proximately two turns. (See figure 28.)