J

EXTENSION ROD

SUPPORTS

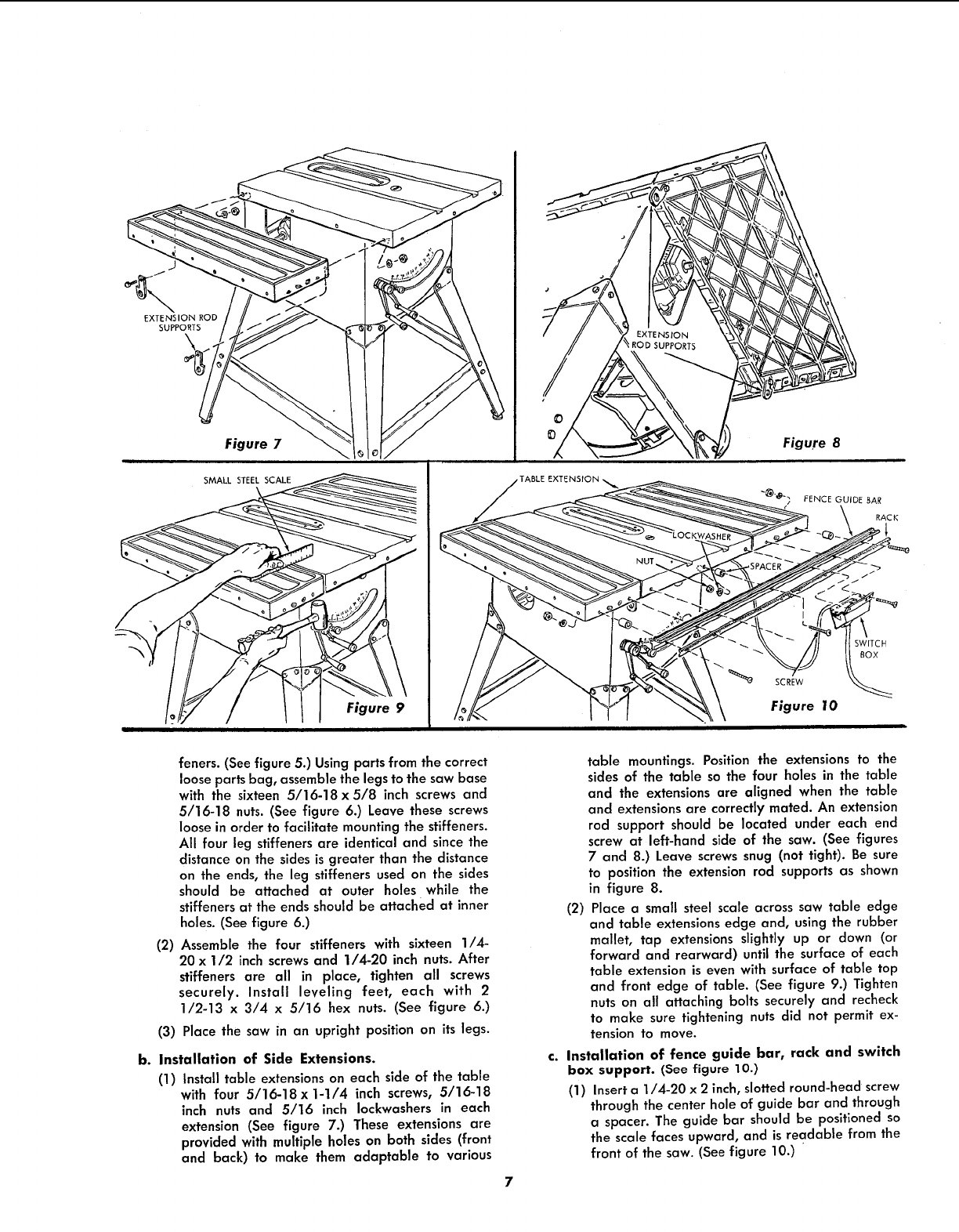

Figure 7

Figure 8

SMALL STEEL SCALE

TABLE EXTENSfON ,_

Figure 9

FENCE GUID_ BAR

RACK

SWITCH

BOX

SCREW

Figure 10

ii

(2)

(3)

feners. (See figure 5.) Using parts from the correct

loose parts bag, assemble the legs to the saw base

with the sixteen 5/16-18x5/8 inch screws and

5/16-18 nuts. (See figure 6.) Leave these screws

loose in order to facilitate mounting the stiffeners.

All four leg stiffeners are identical and since the

distance on the sides is greater than the distance

on the ends, the leg stiffeners used on the sides

should be attached at outer holes while the

stiffeners at the ends should be attached at inner

holes. (See figure 6.)

Assemble the four stiffeners with sixteen 1/4-

20 x 1/2 inch screws and 1/4-20 inch nuts. After

stiffeners are all in place, tighten all screws

securely. Install leveling feet, each with 2

1/2-13 x 3/4 x 5/16 hex nuts. (See figure 6.)

Place the saw in an upright position on its legs.

b. Installation of Side Extensions.

(1) Install table extensions on each side of the table

with four 5/16-18x 1-1/4 inch screws, 5/16-18

inch nuts and 5/16 inch Iockwashers in each

extension (See figure 7.) These extensions are

provided with multiple holes on both sides (front

and back) to make them adaptable to various

table mountings. Position the extensions to the

sides of the table so the four holes in the table

and the extensions are aligned when the table

and extensions are correctly mated. An extension

rod support should be located under each end

screw at left-hand side of the saw. (See figures

7 and 8.) Leave screws snug (not tight). Be sure

to position the extension rod supports as shown

in figure 8.

(2) Place a small steel scale across saw table edge

and table extensions edge and, using the rubber

mallet, tap extensions slightly up or down (or

forward and rearward) until the surface of each

table extension is even with surface of table top

and front edge of table. (See figure 9.) Tighten

nuts on all attaching bolts securely and recheck

to make sure tightening nuts did not permit ex-

tension to move.

c. Installation of fence guide bar, rack and switch

box support. (See figure 10.)

(1) Inserta 1/4-20 x 2 inch,slotted round-head screw

through the center hole of guide bar and through

a spacer. The guide bar should be positioned so

the scale faces upward, and is readable from the

front of the saw. (See figure 10.)