operating controls

OPERATING CONTROLS

Before operating the saw, the operator should examine all

controls until thoroughly familiar with their functions, as

well as making sure that controls are operating properly.

(See figure 39.)

CAUTION: Under no circumstances should

a blade with a diameter greater than 12

inches be used with this saw.

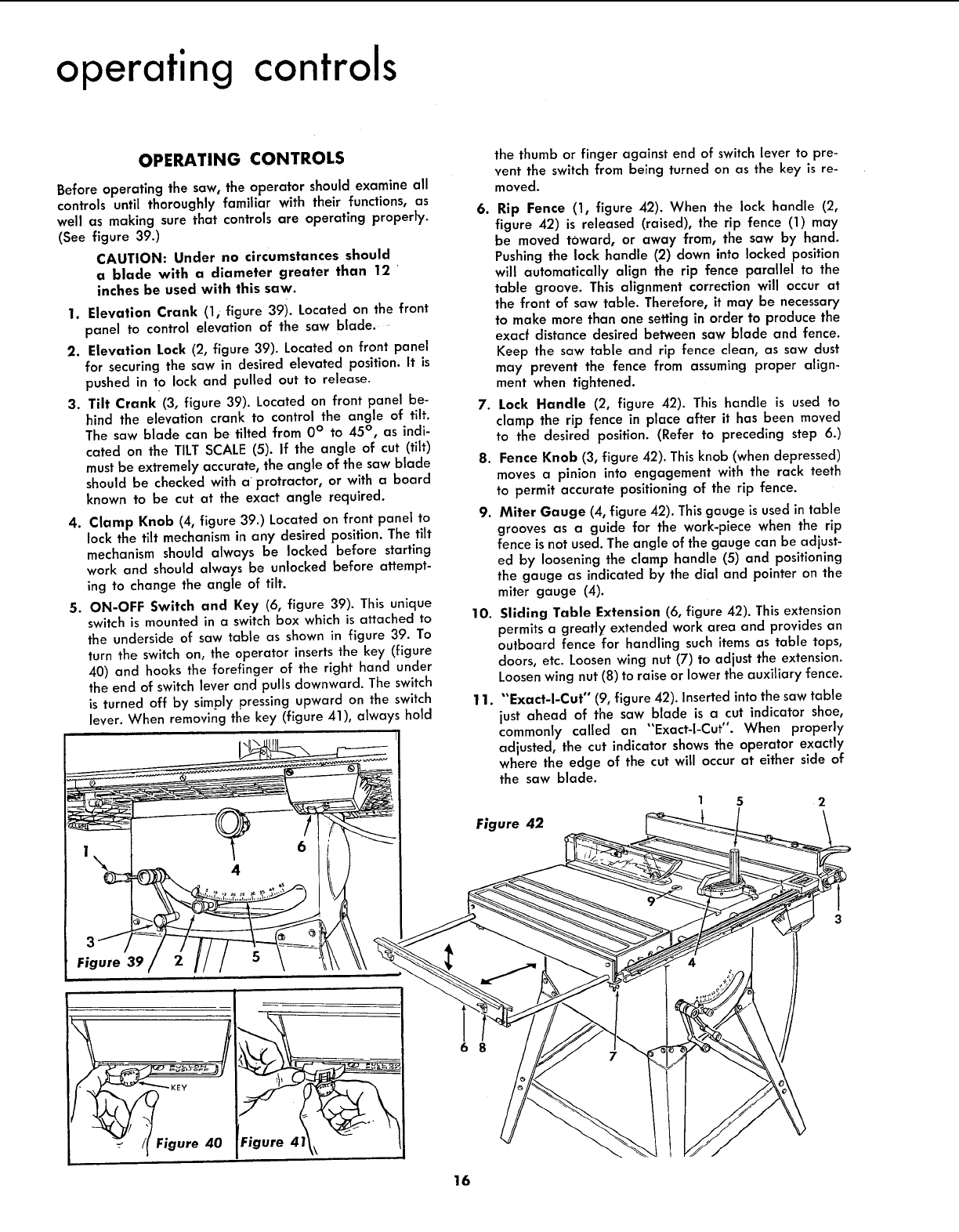

1. Elevation Crank (li figure 39i. Located on the front

panel to control elevation of the saw blade,

2. Elevation Lock (2, figure 39). Located on front panel

for securing the saw in desired elevated position. It is

pushed in to lock and pulled out to release.

3. Tilt Crank (3, figure 39). Located on front panel be-

hind the elevation crank to control the angle of tilt.

The saw blade can be tilted from 0° to 45 °, as indi-

cated on the TILT SCALE (5). If the angle of cut (tilt)

must be extremely accurate, the angle of the saw blade

should be checked wffh a protractor, or with a board

known to be cut at the exact angle required.

4. Clamp Knob (4, figure 39.) Located on front panel to

lock the tilt mechanism in any desired position. The tilt

mechanism should always be locked before starffng

work and should always be unlocked before attempt-

ing to change the angle of tilt.

5. ON-OFF Switch and Key (6, figure 39). This unique

switch is mounted in a switch box which is attached to

the underside of saw table as shown in figure 39. To

turn the switch on, the operator inserts the key (figure

40) and hooks the forefinger of the right hand under

the end of switch lever and pulls downward. The switch

is turned off by simply pressing upward on the switch

lever. When removing the key (figure 41), always hold

1

\

4

3

Figure 39

the thumb or finger against end of switch lever to pre-

vent the switch from being turned on as the key is re-

moved.

6. Rip Fence (1, figure 42). When the lock handle (2,

figure 42) is released (raised), the rip fence (1) may

be moved toward, or away from, the saw by hand.

Pushingthe lock handle (2) down into locked position

will automatically align the rip fence parallel to the

table groove. This alignment correction will occur at

the front of saw table. Therefore, it may be necessary

to make more than one setting in order to produce the

exacf distance desired between saw blade and fence.

Keep the saw table and rip fence clean, as saw dust

may prevent the fence from assuming proper align-

ment when tightened.

7. Lock Handle (2, figure 42). This handle is used to

clamp the rip fence in place after it has been moved

to the desired position. (Refer to preceding step 6.)

8. Fence Knob (3, figure 42). This knob (when depressed)

moves a pinion into engagement with the rack teeth

to permit accurate positioning of the rip fence.

9. Miter Gauge (4, figure 42). This gauge is used in table

grooves as a guide for the work-piece when the rip

fence is not used. The angle of the gauge can be adjust-

ed by loosening the clamp handle (5) and positioning

the gauge as indicated by the dial and pointer on the

miter gauge (4).

10. Sliding Table Extension (6, figure 42). This extension

permits a greatly extended work area and provides an

outboard fence for handling such items as table tops,

doors, etc. Loosen wing nut (7) to adjust the extension.

Loosen wing nut (8) to raise or lower the auxiliary fence.

11. "'Exact-I-Cut" (9, figure 42). Insertedintothe saw table

just ahead of the saw blade is a cut indicator shoe,

commonly called an "Exact-I-Cut". When properly

adjusted, the cut indicator shows the operator exactly

where the edge of the cut will occur at either s_de of

the saw blade.

2

Figure 42

-KEY

Figure 40 Figure 41

6 8

16