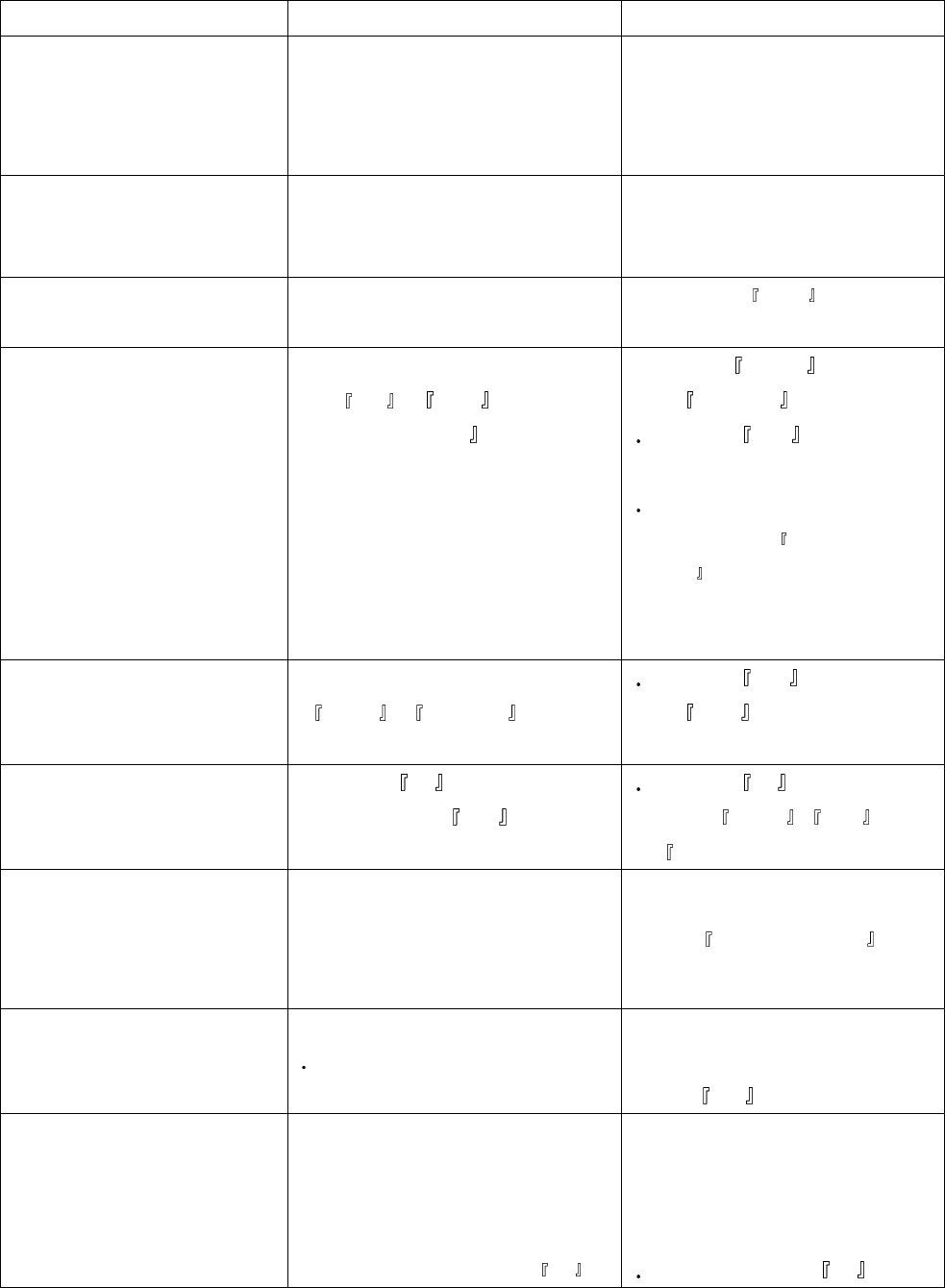

38

Symptoms Presumable Causes Actions

1. Insufficient Oil 1. Replenish Oil

2.

High Water Temperature,

2. Keep the rated

Insufficient Coolant/Water Replenish coolant/water

The engine starts but

stalls immediately

3. Unable to charge 3. Repair

Black or white smoke exhaust

from the muffler successively

1. Overload 1. Keep the rated output

1. Stop Solenoid Disorder

1. Turn the lever to CLOSE

The engine wont stop

to stop and repair

1. Output Selector Switch 1. Change to SINGLE

at ECO

or DUAL or REGULAR

2. Freq. Switch at 50Hz 2 Change to 60Hz

3. Current Dial Position

3. Turn it clockwise more

4. Poor Contact on Cables

4 Connect sufficiently

5. Improper Diameter or Length of Cable

5. Change the cable as per SELECTION – WELD

CABLES

6. Poor Contact to material

6. Connect securely

Welding Arc is weak

7. Simultaneous use 7. Stop using AC Output

1. Output Selector Switch

1 Change to ECO

at SINGLE or

REGULAR

or DUAL

Welding Arc is too

strong

2. Current Dial Position 2. Turn it counterclockwise more

1. Breaker at ON 1 Change to ON

NO AC Output

2.Selector Switch at ECO

2. Change to SINGLE , DUAL o

REGULAR

1. Wrong Frequency

1. Change to the load frequency

2. The rated current of load exceeds the rated

output of the equipment

2. Refer to OUTPUT LIMITATION

Weak AC Output

3. Simultaneous use Stop welding

1. Welding Cable short-circuit

1. Repair the short-circuit

Slow-down does not

activate

2 The power consumption

Of the load is 0.5A or below

2. Chang the slow-down

switch to OFF

1. Connected to AC100/110V receptacle by mistake

1. Connect to the remote control

receptacle

2. Connected AC100V load to remote control

receptacle

2. Disconnect the AC100V plug

Remote Control does

not work

3. The switch (breaker) on the cord reel at OFF

3 Change the switch to ON