-44-

W1770 21" Bandsaw w/Foot Brake

MAINTENANCE

MAINTENANCE

For optimum performance from your machine, follow this

maintenance schedule:

Daily

• Check/correctloosemountingbolts.

• Check/correct damaged saw blade.

• Check/correct worn or damaged wires.

• Correct any other unsafe condition.

Monthly

• CheckforV-belttension,damage,orwear.

• Removebladeandthoroughlycleanallbuilt-upsaw-

dust from the rubber tires on the wheels.

• Clean/vacuum dust buildup from inside cabinet and

off motor.

General

Lubrication

Since all bearings are sealed and perma-

nently lubricated, simply leave them alone

until they need to be replaced. Do not

lubricate them.

This machine does need lubrication in

other places. Do not over-lubricate. Too

much lubrication will attract dirt and

sawdust. Lubricate the following areas as

needed to maintain smooth function of the

bandsaw.

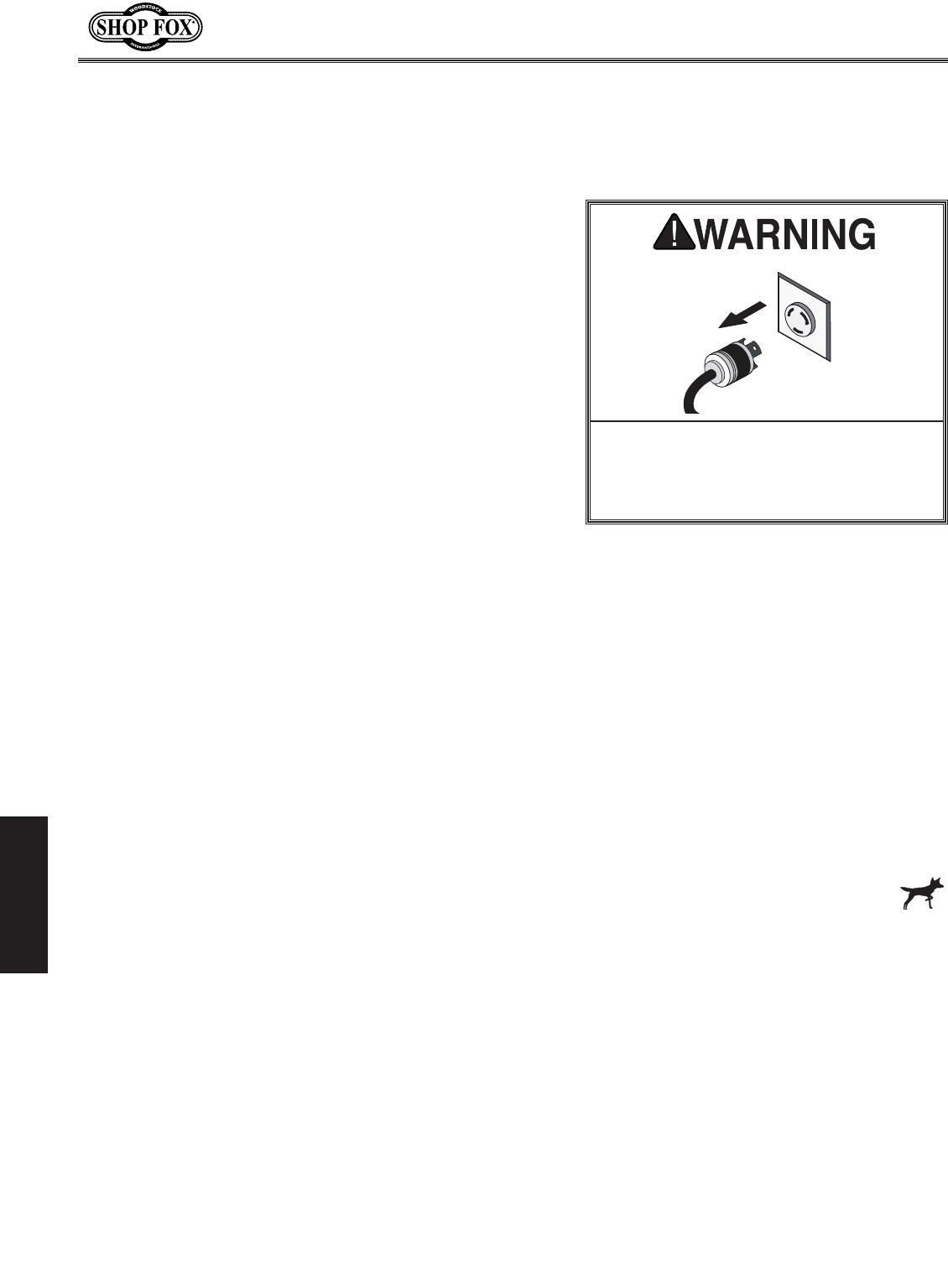

MAKE SURE that your machine is

unplugged during all maintenance pro-

cedures! If this warning is ignored, seri-

ous personal injury may occur.

Protect the unpainted cast iron surfaces on the table by

wiping the table clean after every use—this ensures mois-

ture from wood dust does not remain on bare metal sur-

faces. Keep the table rust-free with regular applications of

general lubricants.

If the table becomes difficult to tilt, remove it and lubri-

cate the trunnion and the slides in the trunnion base with

multi-purpose grease (see Page 46).

Table & Base

Vacuum excess wood chips and sawdust, and wipe off

the remaining dust with a dry cloth. If any resin has built

up, use a resin dissolving cleaner to remove it. Treat all

unpainted cast iron and steel with a non-staining lubricant

after cleaning.

Cleaning

Brushes

The bandsaw is equipped with two lower brushes. The

brushes should be checked daily and cleaned when they

become dirty. There are adjustment brackets that allow

the brushes to be adjusted for bristle wear. Refer to

Adjusting Brushes on Page 50 for adjustment details.

Continued on next page