-56-

Df[\cN(/(0&N(/)'D]^%J`eZ\()&('

FG<I8K@FEJ

1"-2"

4"-5"

1

/

4

"-

3

/

8

" Slot

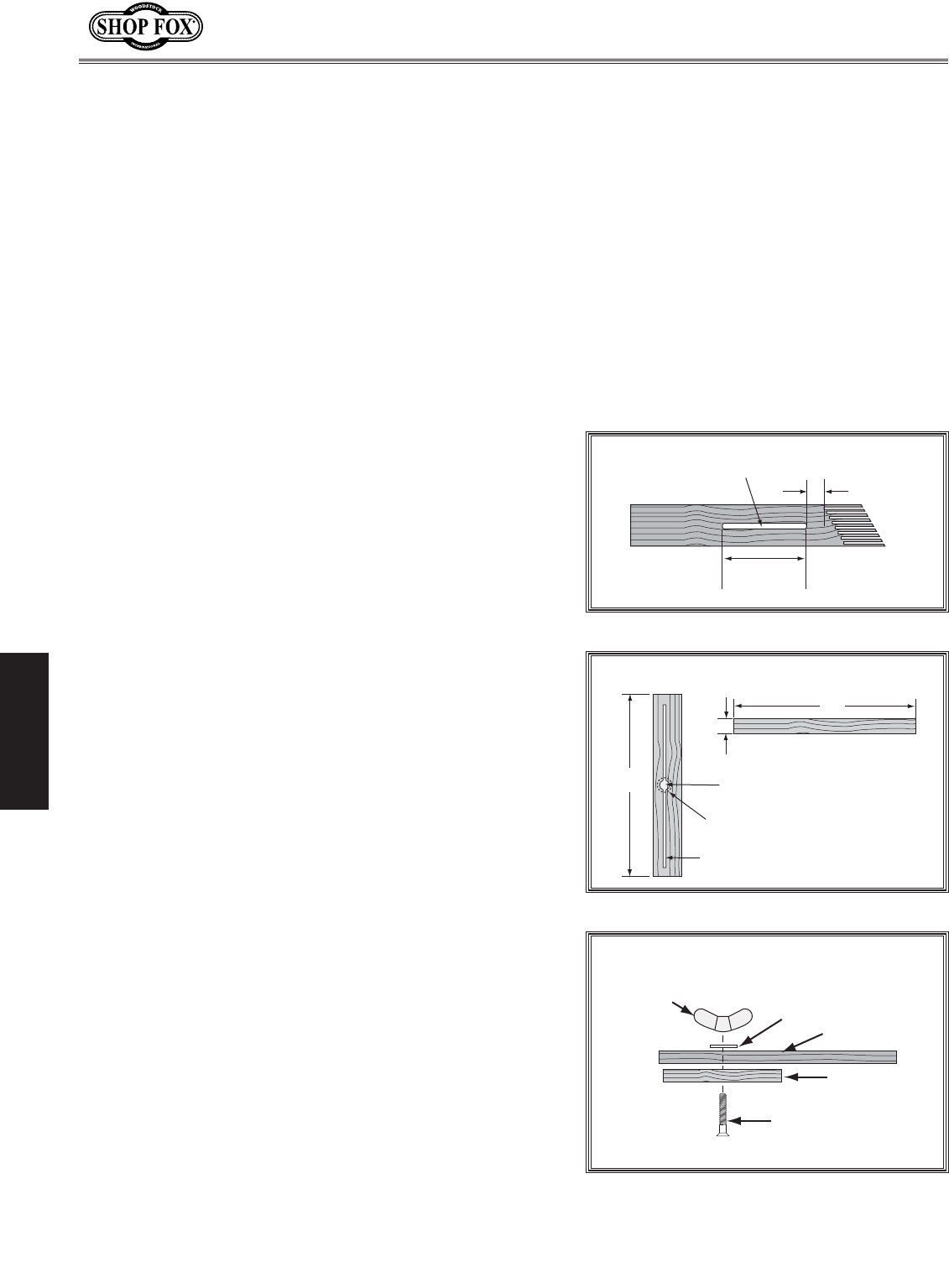

=`^li\.(% Slot routed in featherboard.

5"

5"

4" Slot

(Top View)

(Side View)

3

/

8

"

Countersink on Bottom

1

/

4

" Hole

=`^li\.)% Miter bar pattern.

(Side View)

Wing Nut

Miter Bar

Featherboard

Flat Head Screw

Flat Washer

=`^li\.*% Assembling miter slot

featherboard components.

+% Rout a

1

⁄4"–

3

⁄8" wide slot 4"–5" long in the workpiece

and 1"–2" from the short end of the featherboard

(see =`^li\.().

,% Cut a miter bar that will fit in the table miter slot

approximately 5" long, as shown in =`^li\.).

K`g1:fej`[\idXb`e^k_\d`k\iYXicfe^\i]ficXi^\i

]\Xk_\iYfXi[jÇXggifo`dXk\cp_Xc]k_\c\e^k_f]k_\

kfkXc]\Xk_\iYfXi[Çkfjlggfikk_\]fiZ\Xggc`\[kf

k_\]\Xk_\iYfXi[[li`e^lj\%

K`g1 K_\c\e^k_f]k_\]cXk_\X[jZi\n[\g\e[jfe

k_\k_`Zbe\jjf]k_\]\Xk_\iYfXi[Çk_fl^_(

(

Ð)kf)

c\e^k_jljlXccpnfib%

Now, proceed to Dflek`e^=\Xk_\iYfXi[`eD`k\i

Jcfk on GX^\,..

-% Drill a

1

⁄4" hole in the center of the bar, then

countersink the bottom to fit a

1

⁄4"-20 flat head

screw.

.% Mark a 4" line through the center of the countersunk

hole, then use a jig saw with a narrow blade to cut

it out.

/% Assemble the miter bar and featherboard with a

1

⁄4"-

20 x flat head screw, flat washer, and a wing nut or

a star knob (see =`^li\.*). Congratulations! Your

featherboard is complete.

*% Make a series of end cuts with the grain,

approximately

3

⁄8"–

1

⁄4" apart and 2"–3" long, as shown

in =`^li\.'(A).

Alternatively, start cuts at 2"-3" deep, then make

them progressively deeper, as shown in =`^li\.'

(B).

@DGFIK8EK1 Cuts made across the grain will result

in weak fingers that easily break when flexed. When

made correctly, the fingers should withstand flexing

from moderate pressure. To test the finger flexibility,

push firmly on the ends with your thumb. If the

fingers do not flex, they are likely too thick (the

cuts are too far apart).