-67-

Df[\cN(/(0&N(/)'D]^%J`eZ\('&('

J<IM@:<

D`k\iJcfkkf9cX[\

GXiXcc\c`jd

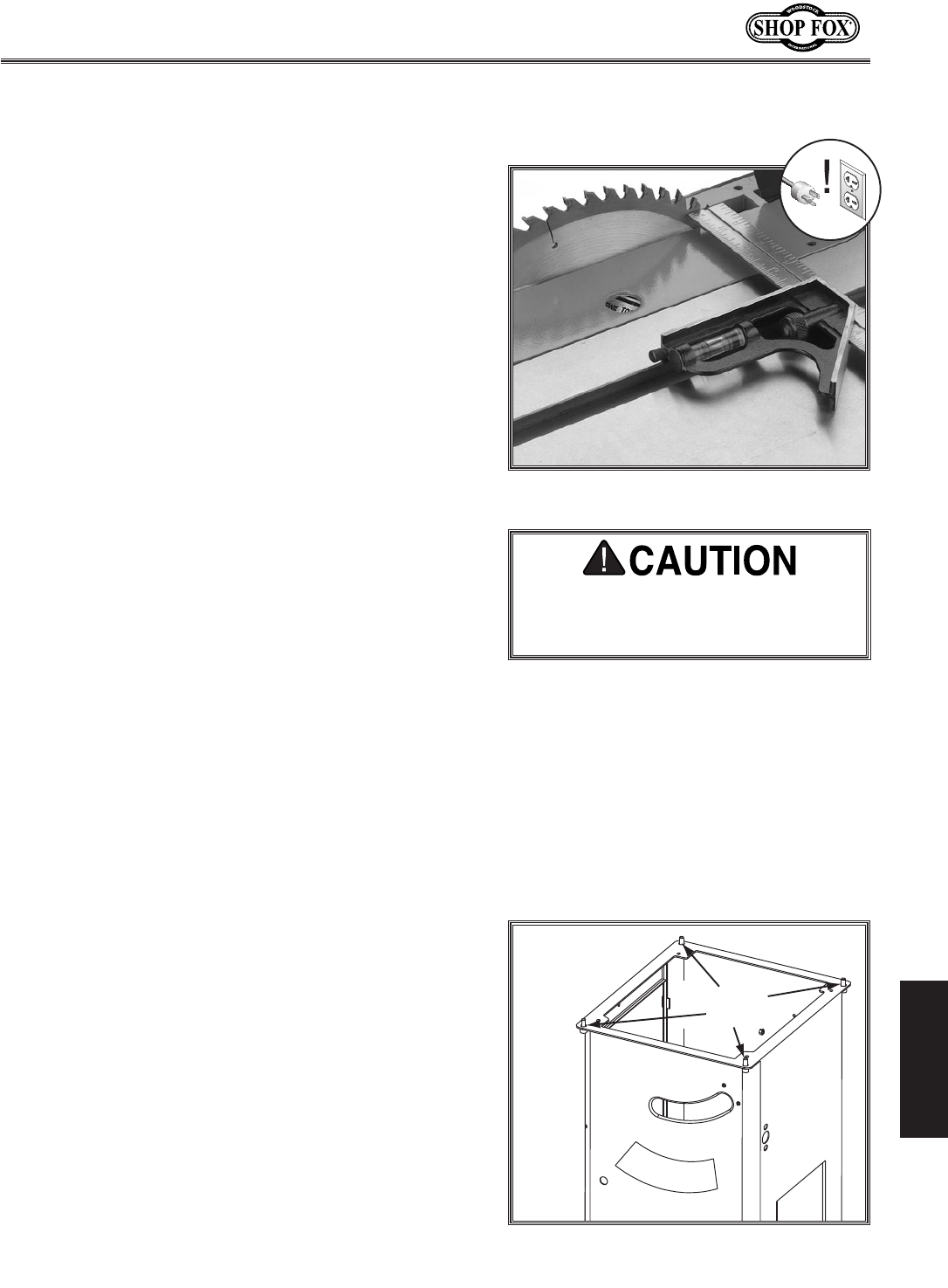

Figure 98. Example of adjusting blade to

miter slot.

Your table saw will give the best results if the miter slot

and the rip fence are parallel to the blade. If either of

these are not exactly parallel, your cuts and your fin-

ished work will be lower in quality, but more importantly,

the risk of kickback will be increased. Take the time to

adjust your table saw properly. A few minutes now will

be time well spent.

KffcjE\\[\[ Hkp

Adjustable Square ..............................................1

Marker ............................................................1

KfX[aljkk_\YcX[\gXiXcc\ckfk_\d`k\ijcfk#[fk_\j\

jk\gj1

(% DISCONNECT THE SAW FROM POWER!

)% Use an adjustable square to measure the distance

from the miter slot to a carbide tip on the blade, as

shown in =`^li\0/. Make sure that the face of the

adjustable square is even along the miter slot.

*% With the end of the adjustable square just touching

the tooth or carbide tip, lock the square in place.

Now, mark the carbide tip with a marker where you

made this measurement.

+% Rotate the marked blade tip to the other end of the

table insert.

,% Slide the adjustable square down to the other end

of the table insert, and compare the distance from

the marked blade tip to the end of the adjustable

square.

— If the blade tip measurement is not the same, the

table will need to be adjusted. Proceed to Jk\g-.

— If the blade tip measurement is the same on both

sides, go to Jk\g..

-% To adjust the table, loosen the four cap screws

in the table mounting locations (see =`^li\00)

and slightly tap the table in the needed direction.

Repeat Jk\gj )Æ,until the blade and miter slot are

parallel.

.% Tighten the table mounting cap screws in a

crisscross, alternating manner.

K_\jXnYcX[\`j[Xe^\ifljcpj_Xig%Lj\

\okiX ZXi\ fi n\Xi ^cfm\j n_\e _Xe$

[c`e^k_\YcX[\finfib`e^e\Xi`k%

Figure 99. Table mounting bolts.

Dflek`e^

9fckj