-78-

Df[\cN(/(0&N(/)'D]^%J`eZ\('&('

J<IM@:<

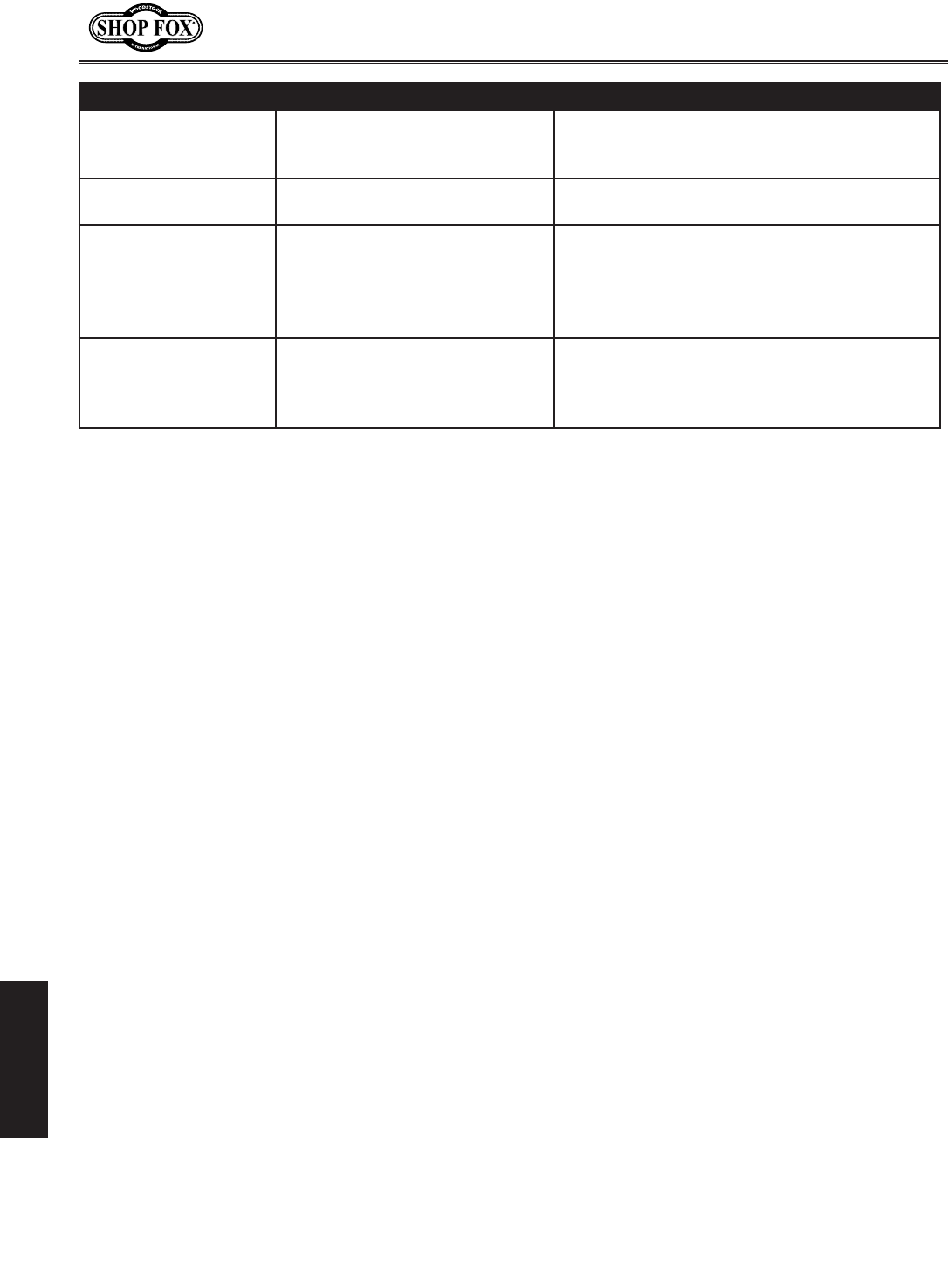

Symptom Possible Cause Possible Solution

Blade is not aligned with

miter slot or fence.

1. Blade is warped.

2. Table top is not parallel to blade.

3. Fence is not parallel to blade.

1. Replace blade (GX^\*,).

2. Make table parallel to blade (GX^\-.).

3. Make fence parallel to blade (GX^\.').

Blade does not reach 90°. 1. 90° stop bolt is out of adjustment.

2. Sawdust stuck on stop bolt.

1. Adjust 90° stop bolt (GX^\-,).

2. Clean sawdust off stop bolt.

Blade hits insert at 45°. 1. 45° stop bolt is out of adjustment.

2. Sawdust stuck on stop bolt.

3. Hole in insert is inadequate.

4. Table out of alignment.

5. Blade position is incorrect.

1. Adjust 45° stop bolt (GX^\-,).

2. Clean sawdust off stop bolt.

3. File or mill the hole in the insert.

4. Align blade to the table (GX^\-.).

5. Adjust blade position.

Board binds or burns when

feeding through table saw.

1. Dull blade.

2. Blade is warped.

3. Fence is not parallel to blade.

4. Table top is not parallel to blade.

1. Replace blade.

2. Replace blade (GX^\*,).

3. Make fence parallel to blade (GX^\.').

4. Make table parallel to blade (GX^\-.).