RW30 USER MANUAL - 19

If VALID key is pressed, torch will move to the starting point

of the next bead.

Torch return to starting point and start welding of the next

bead.

When resurfacing is over, the following message proposes

to set a new resurfacing cycle:

If VALID key is pressed, you will have to set a new welding

area. (As previously seen).

If RESET key is pressed:

Allow to place the torch in « Parking » position.

If VALID key is pressed, torch will move to « Parking » posi-

tion.

If RESET key is pressed, back to message:

Note: This is also effective during all welding cycle.

To go to the next step press the VALID key.

To step back to the previous, press the RESET key.

Welding speed displayed cm/min (1 cm/min equals to 0.4

inch/min) (adjustable value in the parameter menu).

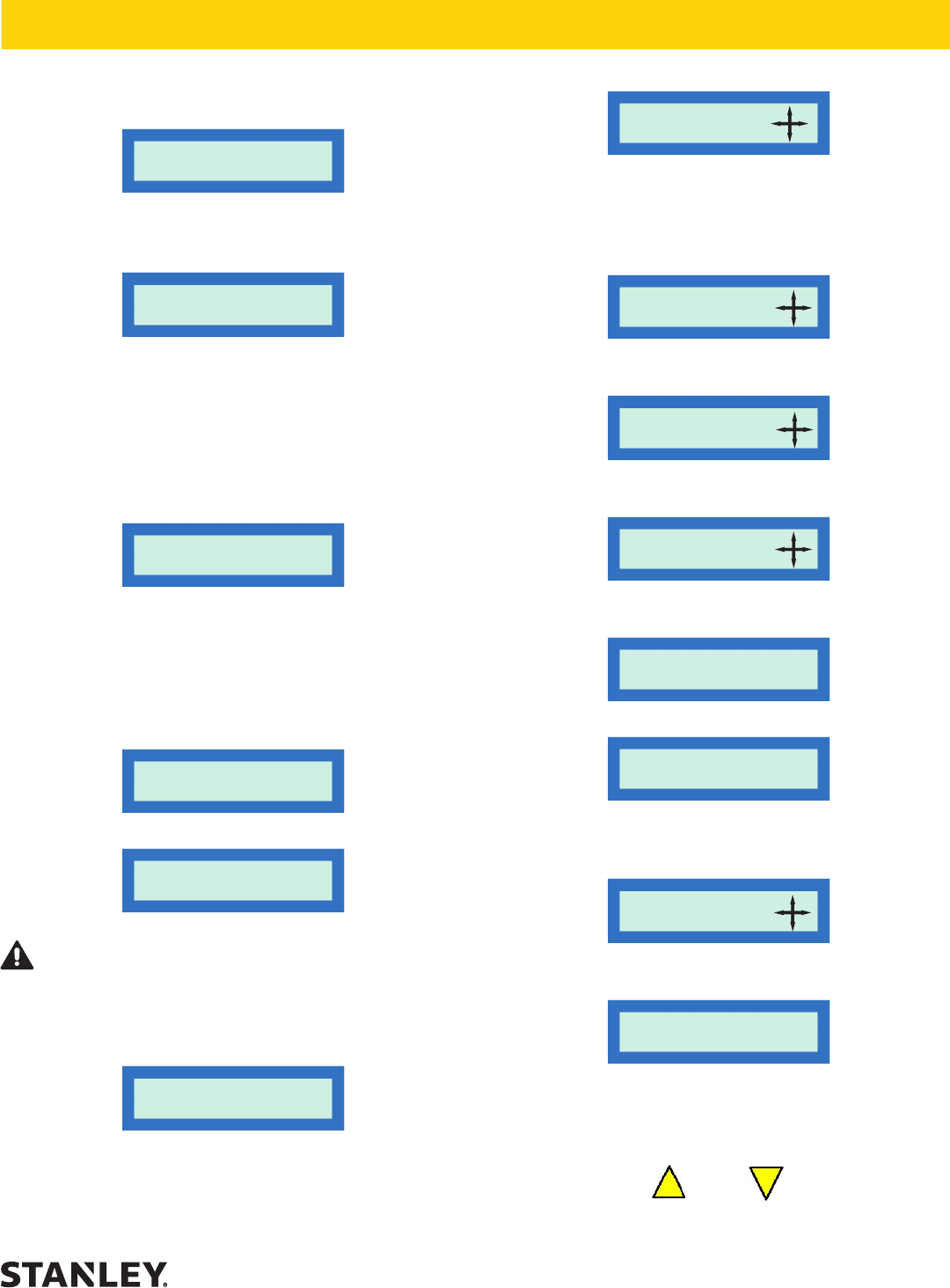

RETURN TORCH TO

INITIAL POINT

END LAYER N : 1

LAYER N : 2 - VAL

NEUTRAL POINT ?

TRANSPORT - VALID

HELLO

NO ALIGNMENT

SPEED : 30

cm/mn

Selection of Torch position after the welding of each bead

(evacuation point).

The setting is done as:

Set point position O1.

Set point position O2.

Set point position O3.

Triangle can be weld: if « NO », set point Position O4. If «

YES », needed number of beads will be display.

Set point position O4.

Display the number of beads that will be made during the

resurfacing (the surrounding is not included in this number).

It is possible to modify this number if needed by pressing:

RETRACTING

POINT

PO1

TORCH:

PO2

TORCH:

PO3

TORCH:

TRIANGLE ?

NO - VALID

TRIANGLE ?

YES - VALID

or

PO4

TORCH:

NUMBER BEADS:

xx

or

OPERATION