Owner Service 15

MAN0155 (Rev. 2/16/2007)

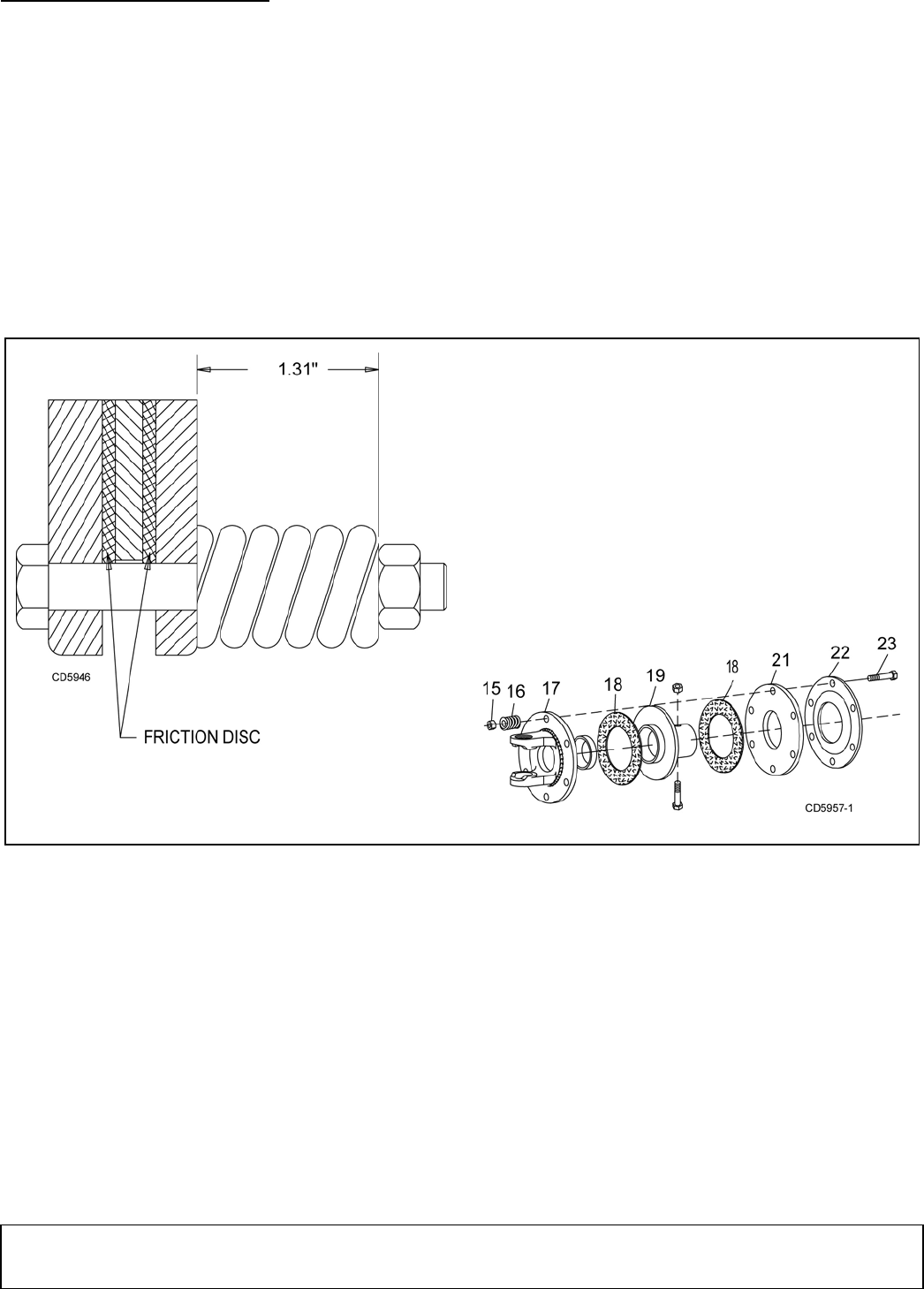

ADJUSTING SLIP CLUTCH

The slip clutch is designed to slip so that the gearbox

and driveline are protected if the cutter strikes an

obstruction.

A new slip clutch or one that has been in storage over

the winter may seize. Before operating the grinder,

make sure it will slip by performing the following opera-

tion:

1. Turn off tractor engine and remove key.

2. Remove driveline from tractor PTO.

3. Loosen eight 10 mm cap screws (23) to remove all

tension from pressure plate (22).

4. Hold clutch support (19) solid and turn shaft to

make sure clutch slips.

5. If clutch does not slip freely, disassemble and clean

the inner clutch plate faces (21), flange yoke (17),

and clutch support (19).

6. Reassemble clutch.

7. Tighten springs (16) until they are compressed to

the 1.31 inches shown in Figure 9.

8. If a clutch continues to slip when the springs are

compressed to the 1.31 inch dimension, check

friction discs (18) for excessive wear. Discs are

1/8" when new. Replace discs after 1/16" wear.

Minimum disc thickness is 1/16".

Figure 9. Slip Clutch Assembly

15. Nut

16. Clutch spring

17. Flanged yoke

18. Friction disc

19. Clutch support

21. Inner clutch plate

22. Pressure plate

23. M10 x 85 mm Cap screw