16 Dealer Service

MAN0155 (Rev. 2/16/2007)

DEALER SERVICE

The information in this section is written for dealer ser-

vice personnel. The repair described here requires

special skills and tools. If your shop is not properly

equipped or your mechanics are not properly trained in

this type of repair, you may be time and money ahead

to replace complete assemblies.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service person-

nel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gan-

grene, serious injury, or death will result. CON-

TACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Never perform service or maintenance with

engine running.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

GEARBOX MAINTENANCE

NOTE: Read this entire section before starting any

repair. Many steps are dependent on each other.

Fill gearbox with 6 pints of SAE 80W or 90W gear lube.

NOTE: Repair to this gearbox is limited to replacing

bearings, seals, and gaskets. Replacing gears, shafts,

and a housing is not cost effective. Purchasing a com-

plete gearbox is more economical.

Inspect gearbox for leakage and bad bearings. Leak-

age is a very serious problem and must be corrected

immediately.

Bearing failure is indicated by excessive noise and

side-to-side or end-play in gear shafts.

Remove Hub

1. Position stump grinder on a hard level surface with

foot pads and jack stand firmly on the ground.

2. Remove hardware and side shield from the right

side of the cutter frame.

3. Remove hardware and cutting wheel from hub.

4. Remove cotter pin (23) and slotted hex nut (14)

from end of horizontal gearbox shaft.

5. Remove hub.

NOTE: You will need to use a heavy duty puller to

remove tapered hub from gearbox shaft.

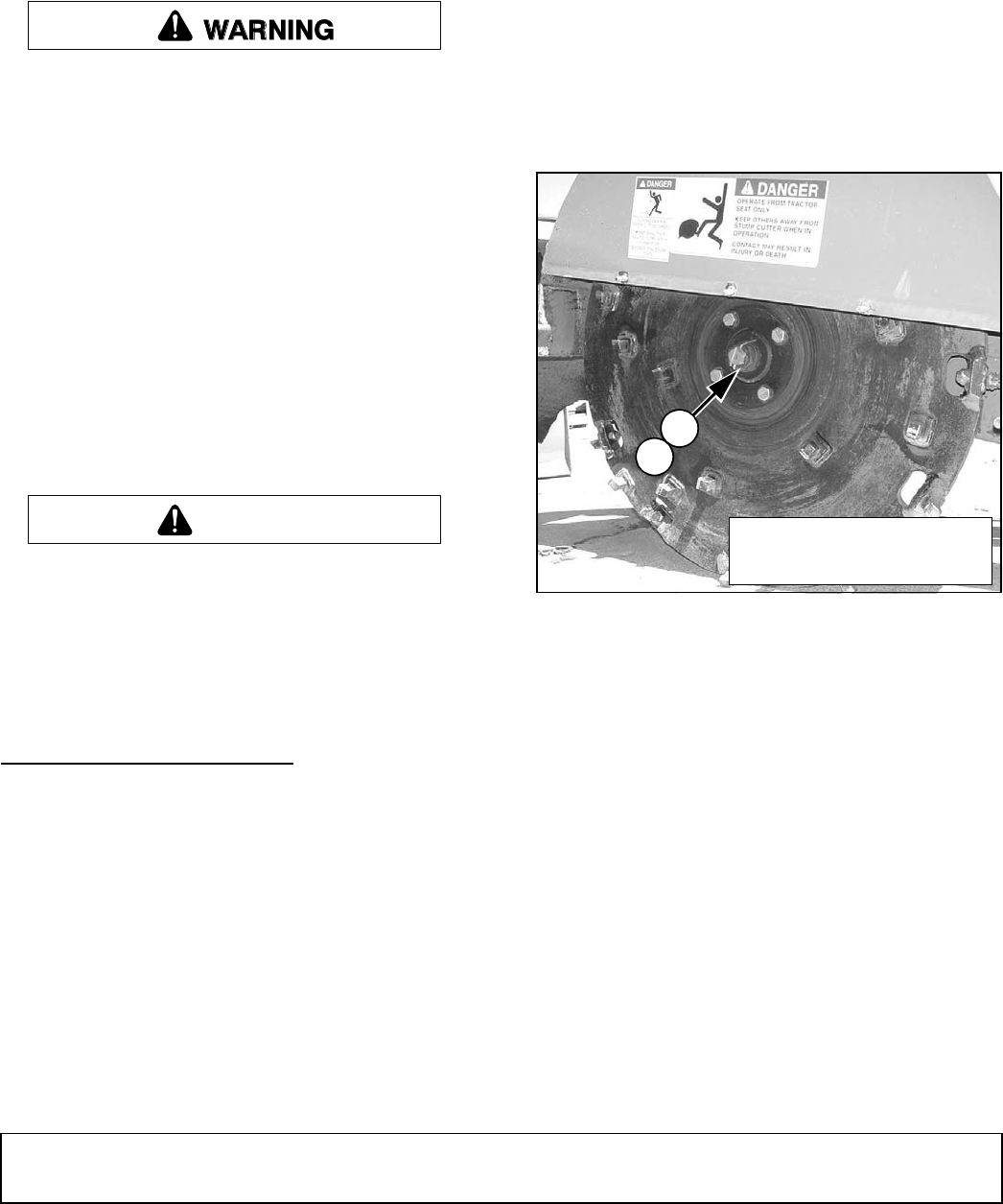

Figure 10. Cutting Wheel and Hub Assembly

(Side Shield Removed)

Remove Gearbox from Stump Grinder

1. Disconnect and remove the driveline from the

tractor.

2. Remove safety pin and clevis pin from top cylinder

mount.

3. Rotate top cylinder out of work area.

4. Disconnect and remove the driveline from the

gearbox.

5. Remove vent plug and siphon gear lube from

housing through this opening.

6. Remove the four bolts that attach gearbox to stump

grinder.

7. Remove gearbox.

CAUTION

DP4

14

23

14. Slotted hex nut M30 x 2

23. Cotter pin B6 x 60