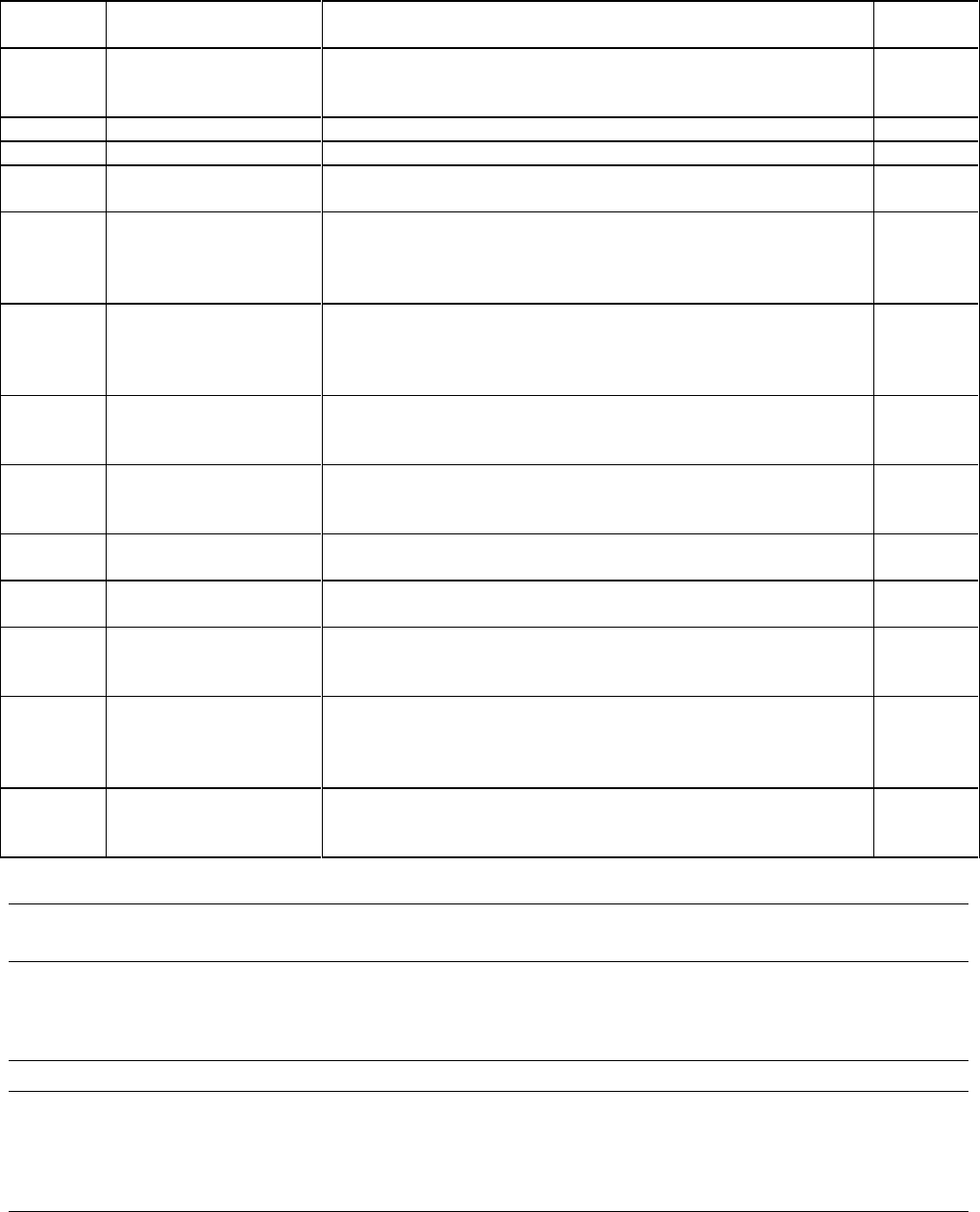

26 Operating Instructions

Table 3-1. Controls and Indicators

Number Controls/Indicators Description Page

1 LINE Switch Pressing at the top of the switch applies ac mains voltage to the units

bias and power circuits. Unit is operational approximately 3 seconds

after power on.

27

2 VOLTAGE CONTROL Clockwise rotation increases the output voltage, 0 to full scale Vdc. 27

3 CURRENT CONTROL Clockwise rotation increases the output current, 0 to full scale Adc. 27

4 OVP ADJUST The recessed, single-turn screwdriver control sets the overvoltage

protection trip voltage

30

5 Voltage Display A 3-1/2-digit display with automatically positioned decimal point

that can indicate output voltage, output voltage setting or

overvoltage shutdown setting. During an error condition, the output

may exceed the display range and the display will indicate + OL.

27

6 Current Display A 3-1/2 digit display with automatically positioned decimal point

that can indicate output current or output current setting. During an

error condition, the output may exceed the display range, and the

display will indicate + OL.

27

7 DISPLAYS SETTINGS

Pushbutton Switch

Causes numeric displays to indicate programmed voltage and current

values, rather than actual output values; allows both settings to be

made without the necessity of opening or shorting load.

33, 34

8 DISPLAY OVP

Pushbutton Switch

Causes VOLTS display to indicate OVP trip voltage, AMPS display

is blanked; allows setting to be made without changing output

settings or load connections

33, 34

9 CV Status Indicator CV (Constant Voltage) indicates that the power supply is regulating

its output at a constant voltage.

33

10 CC Status Indicator CC (Constant Current) indicates that the power supply is regulating

its output at a constant current.

34

11 UNREGULATED Status

Indicator

UNR (Unregulated) indicates that the power supply is operating

beyond its maximum output power specification and that the output

is not regulated or has been shutdown by a protective circuit.

31, 32

12 OVERVOLTAGE Status

Indicator

OV (Overvoltage) indicates that the power supply output has been

shut down and latched by the occurrence of an overvoltage

condition. Removing the cause of the overvoltage and turning the

supply off and back on will reset the unit.

31

13 OVERTEMPERATURE

Status Indicator

OT (Over temperature) indicates an overheating condition on either

the diode or FET boards. OT automatically resets when the

temperature drops to a safe operating level.

31

Turn-On Checkout Procedure

WARNING: Before the instrument is turned on, all protective earth terminals, extension cords, and devices

connected to the power supply should be connected to a protective earth ground. Any

interruption of the protective earth grounding will cause a potential shock hazard that could

result in personal injury.

Caution: This instrument can be damaged by electrostatic discharge into the control connectors, or the switches

on the rear panel even while the unit is turned on. Do not cause an electrostatic discharge into these

connectors and switches (which may occur when they are touched). Also, consistent with good

engineering practice, leads attached to customer accessible signal/monitoring ports should be twisted

and shielded to maintain the instruments specified performance.

The following procedure ensures that the supply is operational, and may be used as an incoming inspection check.