18

Table 13 — Minimum Gpm Required for

Water-Cooled Heads and/or Oil Cooler

(Based on 30° F Rise)

SAFETY RELIEF VALVES — All 5H compressors are

equipped with built-in safety relief valves that are factory set to

relieve from discharge to suction side of the compressor at a

pressure differential of 350 psi.

Safety relief valves that relieve at a 400 psi pressure differ-

ential are factory installed on the 5F60 compressor but are not

available with smaller 5F compressors.

SUCTION STRAINERS — Each 5F,H compressor is

equipped with one or 2 suction strainers located in the suction

manifold. On new installations, felt filters should be used in

suction strainers to trap foreign material left after installation.

After 50 hours of use, these felt filters must be removed. See

5F,H Installation Instructions for further details.

OIL SAFETY SWITCH — An oil safety switch is provided

as standard with all compressors except 5F20 and 5F30. This

switch is optional equipment on 5F20 and 5F30 compressors.

This switch will shut off the compressor before high oil

temperatures or lack of oil causes loss of oil pressure which can

result in compressor failure. As a safety feature, this switch

must be reset manually after cutout.

OIL SEPARATORS — Oil separators in the hot gas discharge

line are not recommended for general use. However, there are

systems where protection afforded by a separator is desirable,

notably systems employing flooded evaporators or refrigera-

tion systems with long system piping. For a more complete

discussion see Carrier’s System Design Manual.

CRANKCASE OIL HEATERS — Crankcase oil heaters are

available for all 5F,H compressors. Heaters keep the crankcase

warm during off cycles and thus minimize refrigerant absorp-

tion in the oil. Crankcase heaters are recommended for CFC or

HCFC refrigerant applications and are required for HFC refrig-

erant applications with POE lubricants. Refer to the 5F,H

Installation Instructions for installation and wiring.

INTERCONNECTION OF COMPRESSORS — All 5F,H

compressors are furnished with removable handhole cover

plates on each crankcase. When field interconnection is desired

on 5F40 through 5H86 compressors, cover plates can be

removed and replaced by special cover plates with tapped open-

ings. These tapped cover plates have connections for both oil

and gas equalizing lines. For interconnection of 5F20 and 5F30

compressors, use the opening for the oil sight glass (see 5F,H

Installation Instructions). Cover plates for interconnection are

standard equipment on 5F120 and 126 compressors.

Many refrigeration systems utilize oil management compo-

nents such as an oil separator, oil reservoir and floats. The oil

level control float an be installed in the sight glass connection

in the 5F,H handhole cover plate.

VIBRATION ISOLATORS — A standard vibration isolation

package is available for each 5F,H compressor. This consists of

a standard rubber-in-shear and compression type mounting that

gives an average static deflection of approximately

1

/

8

in. and

provides reasonably good vibration isolation at 1750 rpm.

The use of vibration isolators is recommended for all com-

pressor and condensing units because:

1. Transfer of vibration to structure is reduced when the

units are installed on upper floors.

2. They limit drive shaft misalignment on installations

where units are bolted to an uneven concrete floor.

Vibration isolators giving approximately

3

/

8

-in. deflection

are available for superior isolation or if the compressor is run at

slower speeds. Tables 14 and 15 provide an estimated weight

distribution on legs of a compressor or condensing unit when

used with a normal horsepower motor.

MUFFLERS — Four standard mufflers cover the entire model

range of 5F,H compressors. It is recommended that these

mufflers be installed when compressors are used with remotely

located water-cooled or evaporative condensers.

Mufflers are not usually necessary with smaller 5F

compressors and their use is recommended only when quiet

operation is required.

Each piping package to convert 5H compressor units to

condensing units includes a standard muffler of appropriate

size.

Pressure drop through mufflers is about

1

/

2

psi at 40 F

suction and 105 F discharge with following loadings: 5 tons

with 5F20 muffler, 15 tons with 5F40 muffler, 35 tons with

5H40 muffler and 100 tons with 5H120 muffler.

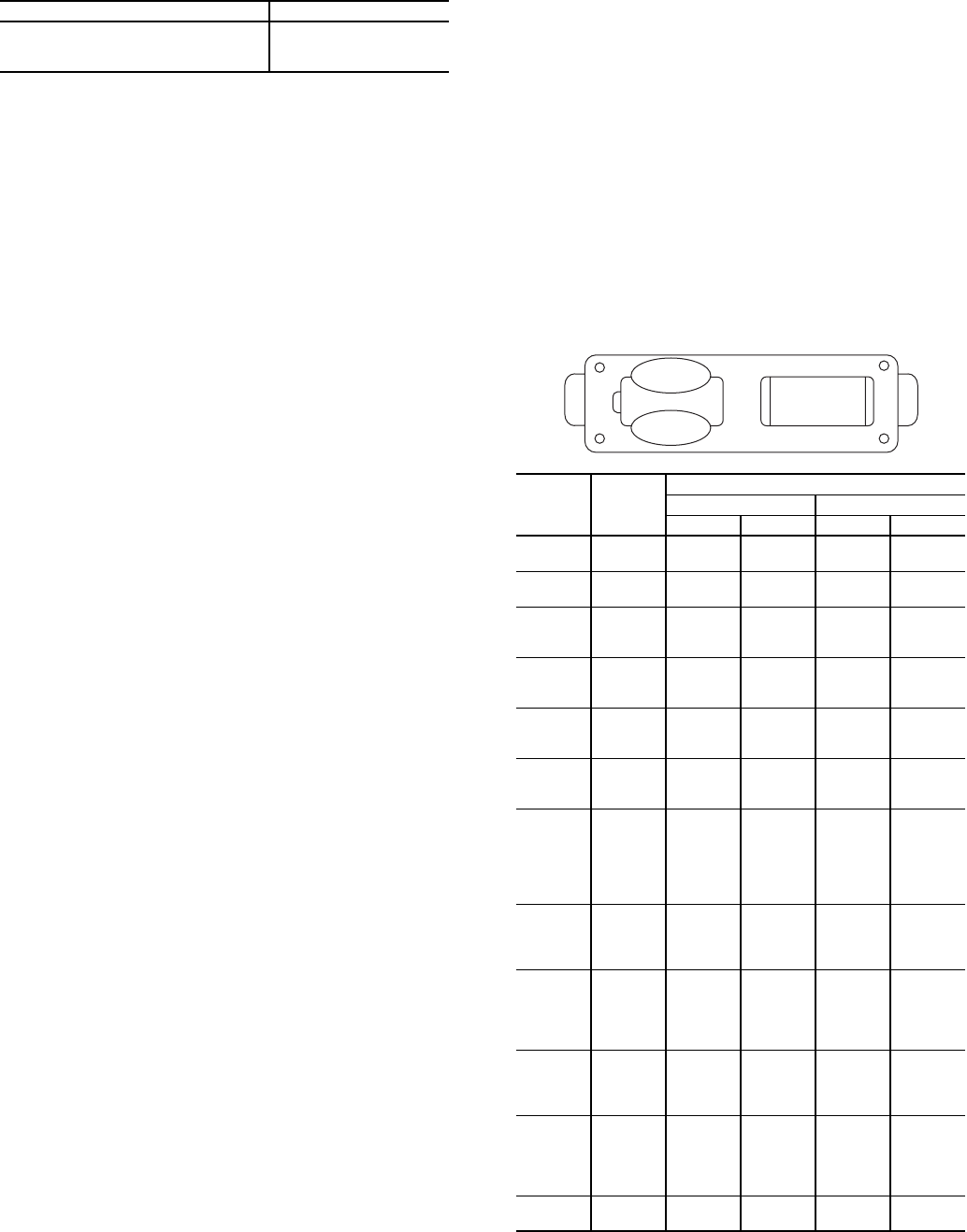

Table 14 — Weight Distribution, Condensing Units

*Oversize frame.

COMPRESSOR GPM

5F

2-3

5H (4, 6 and 8 Cylinders)

6

5H (12 Cylinders)

8

COMPR

COND

SIZE

WEIGHT DISTRIBUTION (lb)

Belt Drive Direct Drive

A or D B or C A or D B or C

5F20

20 138 115 ——

30 148 125 ——

5F30

20 163 135 ——

30 170 148 ——

5F40

30 280 220 ——

40 325 263 305 240

60 345 285 325 265

5F60

40 365 305 ——

60 406 345 360 305

027 ——470 430

5H40

60 525 423 ——

027 585 478 555 450

043 665 603 580 505

5H46

043 ——580 505

054 ——610 535

070 ——625 550

5H60

027 693 570 ——

043 745 625 710 590

054 825 818 755 635

054* 915 823 ——

070 930 833 765 645

084 ——960 865

5H66

054 ——755 635

070 ——765 645

084 ——690 865

097 ——1030 935

5H80

043 1023 803 ——

054 1065 848 985 900

070 1075 858 995 910

084 1163 943 1080 995

097 1185 1018 1150 1065

5H86

070 ——995 910

084 ——1030 995

097 ——1150 1065

127 ——1300 1215

5H120

054 1335 1008 ——

070 1350 1023 1280 1080

084 1425 1098 1340 1140

097 1493 1163 1385 1185

127 ——1535 1335

5H126

097 ——1325 1185

127 ——1535 1335

MOTOR

C

B

COMPR

D

A