21

Table 17 — Initial and Final Unloading

Oil Pressures — 5F20, 5F30

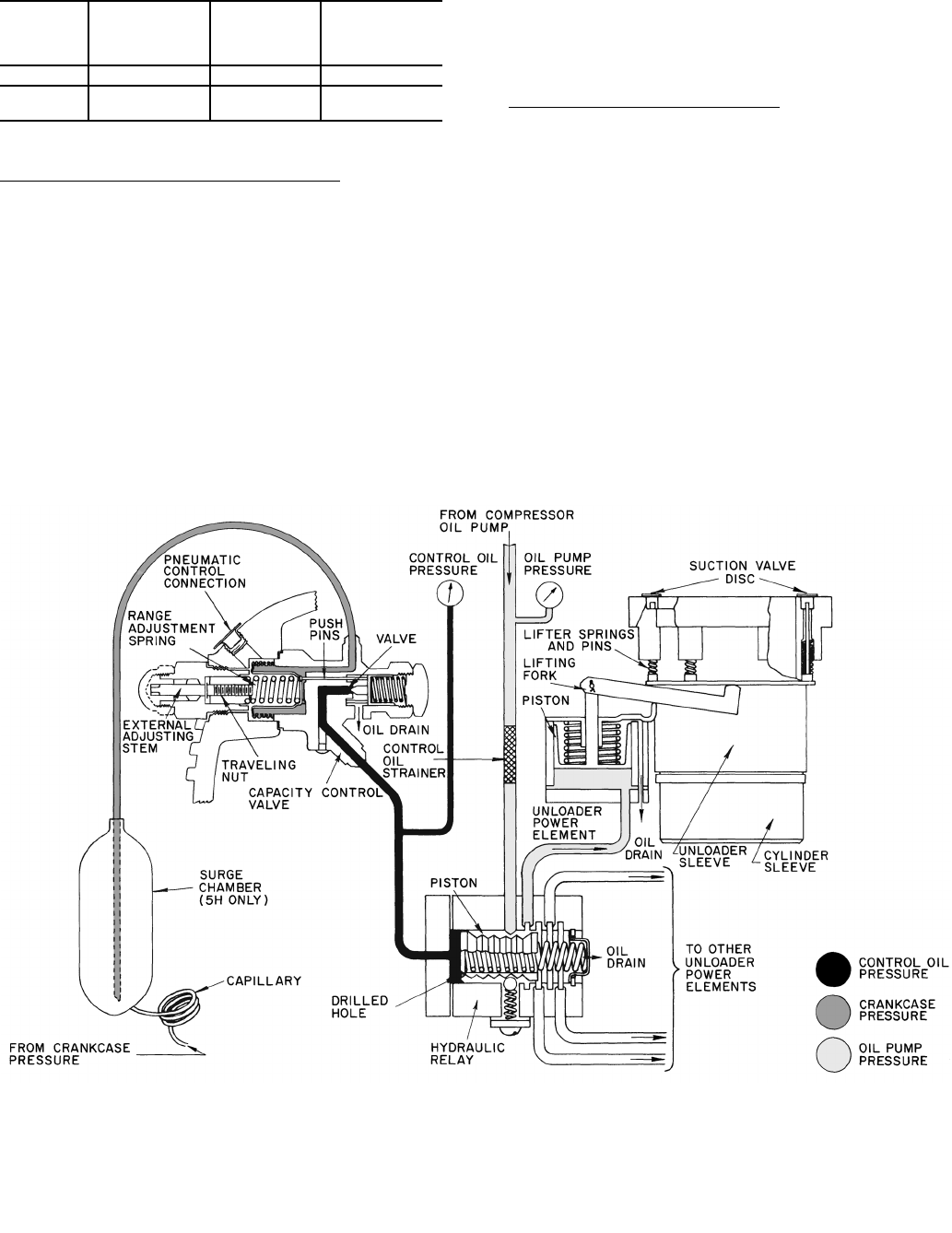

5F40 THROUGH 5H86 (Fig. 7)

Major Elements of Capacity Control Systems:

1. Capacity Control Valve: Function is to raise or lower the

control oil pressure to the hydraulic relay piston in

response to refrigerant suction pressure. Increase in

suction pressure increases control oil pressure in the hy-

draulic relay.

2. Hydraulic Relay: Function is to feed lubrication oil from

the oil pump at full pressure in sequence to one or more

power elements. Relay is activated by control oil pressure

from the capacity control valve.

3. Power Element: Supplies power to operate the valve

lifting mechanism.

4. Valve Lifting Mechanism: Consists of a sleeve and push

pin assembly around each controlled cylinder, designed

to hold the suction valve open, or to permit the valve to

remain in a normal operating position depending on its

actuation by the power element.

Principle of Operation of the System

— A decrease in suc-

tion gas pressure, which necessitates a decrease in compressor

capacity, causes the range spring to open the capacity control

modulating valve. This allows control oil to relieve from the

hydraulic relay and thus reduces control oil pressure in the

relay. With reduced control oil pressure, the spring in the

hydraulic relay moves a piston and thus lubrication oil from the

oil pump is prevented from flowing to a particular deactivated

power element. This relieves oil pressure from the power

element allowing the spring in the power element to move the

lifting fork and unload the cylinder. An increase in suction

pressure reverses action and loads cylinders.

COMPR

NO. OF

CONTROLLED

CYLINDERS

START TO

UNLOAD

OIL PRESS.

(psi)

COMPLETELY

UNLOADED

OIL PRESS.

(psi)

5F20

1 19.8 13.0

5F30

1 30.0 20.2

2 19.8 13.0

Fig. 7 — Capacity Control — 5F40, 60; 5H40, 46, 60, 66, 80 and 86