2

OPEN-DRIVE COMPRESSORS

These compressors are designed to operate with Refriger-

ants 12, 22, 134a, 502, or 507/404A. See Table 1.

Operating Requirements —

Satisfactory operation of

a reciprocating compressor depends on 3 fundamental

requirements:

1. Prevention of excess discharge temperature.

2. Adequate compressor lubrication.

3. A clean and dry system.

Discharge Temperature —

The temperature at the

discharge valves within the cylinders is a controlling factor.

Some cooling of the discharge gas occurs before reaching the

discharge stop valve, thus when water-cooled heads are used,

this cooling is greater than it is without water cooling. To pre-

vent excessive temperature at the compressor discharge valves,

the following temperatures, when measured immediately

following the discharge stop valve, must never be exceeded:

For nonwater-cooled heads . . . . . . . . . . . . . . . . . . 275 F max

For water-cooled heads . . . . . . . . . . . . . . . . . . . . . 250 F max

The approximate discharge gas temperature can be found

by using the following equation:

Where:

T

2

= Discharge temperature, F absolute

T

1

= Suction temperature, F absolute (including

superheat)

P

2

= Discharge pressure, psia

P

1

= Suction pressure, psia

N = Compression exponent of the gas (see Table 2)

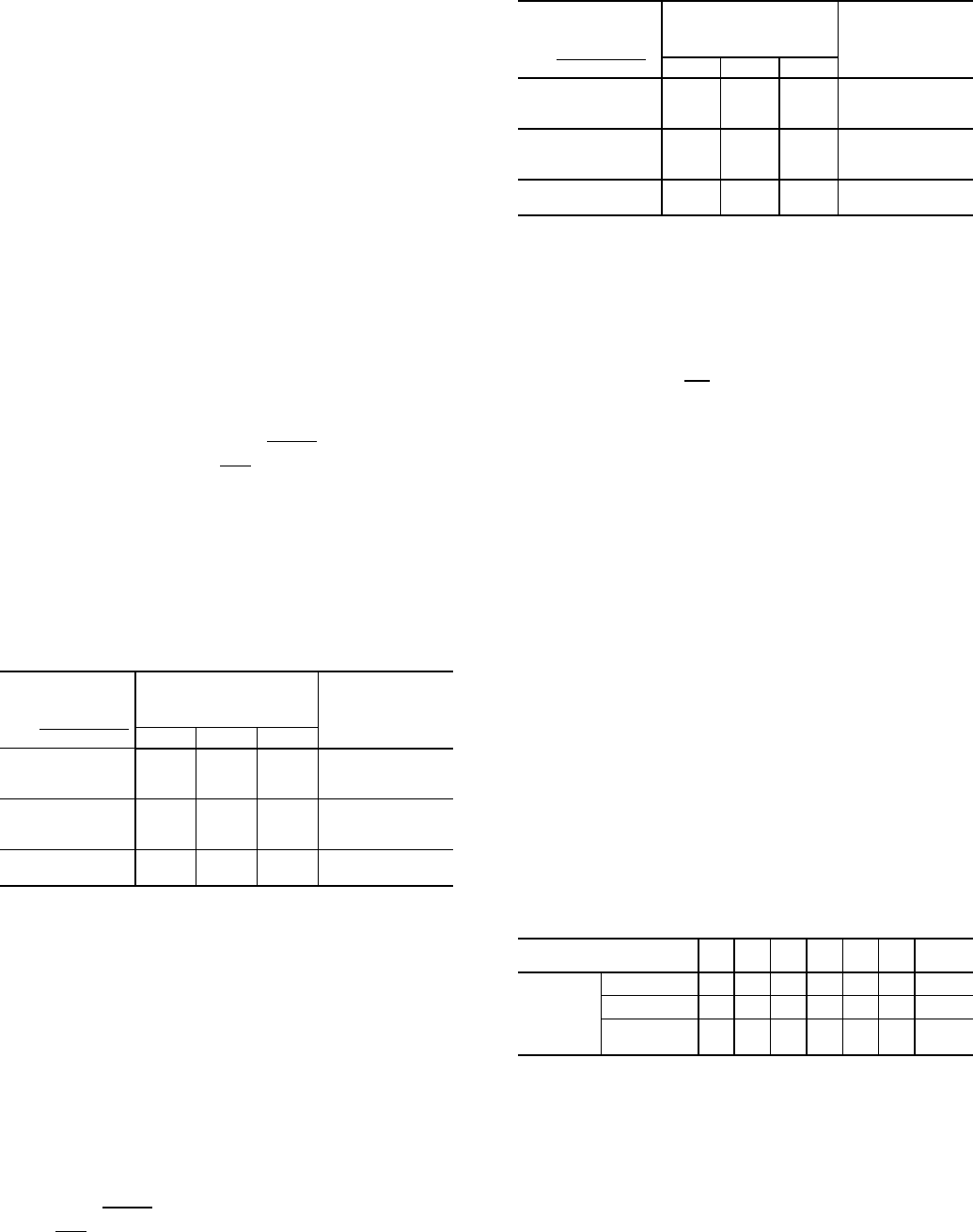

Table 2 — Compression Exponent “N”

*For R-134a and R-507/404A refer to the Carlyle Compressor Selection

program (http://www.carlylecompressor.com/TechnicalInfo/Carwin.htm) to

determine discharge temperature. The selection program can also be

used for R-22 and R-502 in place of the discharge temperature formulas.

The value of compression exponent “N” depends upon the

properties of gas compressed, degree of cooling in compressor

jacket, leakages, etc.

To simplify discharge temperature calculations, the preced-

ing formula may be stated in the following form:

T2 = [(460 + T1) x C] – 460

Where:

T2 = Discharge temperature, F actual

T1 = Suction gas temperature, F actual (including

superheat)

Values for “C” at various compression ratios are listed in

Table 3.

Table 3 — “C” Factors

*For R-134a and R-507/404A refer to the Carlyle Compressor Selection

program (http://www.carlylecompressor.com/TechnicalInfo/Carwin.htm) to

determine discharge temperature. The selection program can also be

used for R-22 and R-502 in place of the discharge temperature formulas.

Example:

Refrigerant 12

Factor C = 1.33

Suction Temperature, T1 = 0° F saturated, superheated

to 65 F

Solution:

T2 = [(460 + 65) x 1.33] – 460

= 698 – 460

= 238 F

Although exponents are shown for high compression ratios,

these are for information only. Rating tables define allowable

selection and operation limits.

High Compression Ratio —

Avoid compressor oper-

ation at compressor ratios exceeding those covered in the rating

tables. For operating conditions outside the limits shown in

these tables, use 2-stage compression. Care must be taken to

prevent the compressor from pulling down to levels outside the

rating tables.

Suction Gas Superheat —

Excessive suction gas super-

heat will result in abnormally high discharge temperatures,

which must be avoided. When using Refrigerants 12, 134a, 502,

and 507/404A it is recommended that the actual suction gas

temperature not exceed the values in Table 4.

Table 4 — Actual Suction Gas Temperature

Limits (F) Refrigerants 12, 134a, 502, and

507/404A*

*With Refrigerant 22, the suction gas superheat should never exceed

25 F for continuous operation.

Keeping Liquid Refrigerant Out of Compres-

sor —

Liquid refrigerant, or excessive amounts of entrained

liquid particles in suction gas must be kept out of the compres-

sor by proper system design and compressor control. Under

operating conditions, presence of unevaporated liquid refriger-

ant in the compressor tends to break down oil film on cylinder

walls, resulting in increased wear and loss of machine capacity.

During compressor operation, proper adjustment of the

expansion valve will prevent excessive amounts of liquid from

entering the compressor.

N – 1

T

2

= T

1

(

P2

)

N

P1

COMPRESSION

RATIO

WITHOUT

WATER-COOLED

HEADS*

WITH

WATER-COOLED

HEADS

R-22

=

Discharge

Suction psia

R-12 R-22 R-502

2

1.216 1.325 1.234 1.240

3

1.191 1.258 1.216 1.218

4

1.177 1.240 1.206 1.205

5

1.172 1.234 1.197 1.199

6

1.166 1.232 1.190 1.196

8

1.160 1.228 1.178 1.192

10

1.155 1.225 1.169 1.187

12

1.150 1.224 1.161 1.182

N – 1

C =

(

P2

)

N

P1

COMPRESSION

RATIO

WITHOUT

WATER-COOLED

HEADS*

WITH

WATER-COOLED

HEADS

R-22

=

Discharge psia

Suction psia

R-12 R-22 R-502

2

1.14 1.17 1.13 1.15

3

1.19 1.25 1.22 1.22

4

1.23 1.31 1.27 1.27

5

1.26 1.36 1.30 1.31

6

1.29 1.40 1.33 1.34

8

1.33 1.47 1.37 1.40

10

1.36 1.53 1.40 1.44

12

1.38 1.57 1.41 1.47

Compression Ratio

P

2

= 8

P

1

SATURATED SUCTION

GAS TEMP

–60 –50 –40 –30 –20 –10

0 AND

ABOVE

Actual

Suction

Gas Temp

R-12

— — 35 45 55 65 65

R-134a

—————— 65

R-502

R-507/404A

25 35 45 55 65 65 65