39

Water Circuiting Arrangements —

The water cir-

cuiting arrangement selected for 5F and 09RH condensers

depends on available condenser water pressure, temperature,

quantity and source. Refer to Table 32.

Refer to the Carrier System Design Manual for specific

information and recommendations for refrigerant and water

piping.

Economics —

Selection of a condenser requires balancing

of certain economic variables, including:

1. First cost of compressor-condenser combination.

2. Operating costs.

3. Ratio between power costs and water costs.

Where first cost is the most important consideration, the

best combination of compressor and condensers has the lowest

total equipment cost.

If owning and operating costs are important, combination

must be selected on basis of both considerations.

A condenser selection that permits operation of the system

at a low condensing temperature, results in the lowest compres-

sor motor brake horsepower and consequently, lowest operat-

ing cost. A condenser selection that is heavily loaded requires

the compressor to operate at a higher condensing temperature

and results in higher compressor motor brake horsepower and

operating cost.

For a given compressor-condenser combination, selection

of a condensing temperature may depend on a ratio between

power costs and water costs, on quantity of water available,

on condensing temperature required to achieve compressor

capacity, or a requirement to remain within allowable loading

on a given motor size.

Condenser Performance with Ethylene Gly-

col —

Increased use of closed circuit cooling towers has led

to a corresponding increase in the need for shell and tube con-

denser ratings for use with ethylene glycol. When towers are

installed outdoors, a brine solution is required for freeze protec-

tion during winter operations.

In most outdoor installations, specifications will call for a

percentage of concentration of ethylene glycol or other brine

solution. If concentration is not specified, it may be the choice

of the contractor to determine a percentage of glycol concentra-

tion to ensure against freeze-up during winter minimum design

ambients.

To perform simplified selection, use Fig. 22 to convert a

condenser water rating to a brine rating.

EXAMPLE:

Assume that a building with a year-round cooling load has a

cooling requirement of 120 tons during summer design condi-

tions. Chilled water design temperatures are 54 F entering to

44 F leaving, and for summer duty, the condenser water is

based on 85 F and a 10 degree rise.

From product literature, selected unit will deliver 121 tons

at 105.8 F saturated discharge temperature (SDT) and has

153 tons of heat rejection.

Determine condenser loading factor by use of following

formula:

Where: EWT — Entering Water Temperature

LF — Loading Factor

THR — Total Heat Rejection

The 85 F value is return water temperature from closed cir-

cuit cooler.

Entering condenser rating data at loading factor of 7.9,

300 gpm are required to maintain design condensing tempera-

ture. Next, determine the rise by:

If a more precise rise is desired, go back and assume a

slightly different condensing temperature, recalculate the load-

ing factor and rise and repeat the procedure until a final balance

is found.

For this example, condenser water pressure drop is approxi-

mately 9.4 ft for the design 300 gpm flow rate. Using Fig. 22,

flow rate correction can be determined for any glycol concen-

tration versus water in shell and tube condensers.

Continuing with example, assume specifications required

protection against freeze-up at an ambient of 0° F. (A glycol

concentration that provides protection between 10 and 15 de-

grees below expected minimum ambient has been the design

criteria for many years.)

In a condenser system, the use of proper ethylene glycol

brine concentration is important because of the phenomenon

that commonly published freeze points are not freeze points but

are the point of crystallization where the first crystals begin to

form. Actual freezing into a solid occurs at much lower

temperatures. For example, freeze point of 20% ethylene

glycol is given as +16 F but does not become a solid until it

reaches –50 F; 35% ethylene glycol with a freeze point of –6 F

does not become solid until it reaches –120 F. Consequently,

20% glycol solution will take care of most domestic applica-

tions and 35% brine should satisfy the rest. The lowest con-

centration of brine will be the most efficient and result in

considerable energy conservation.

Entering Fig. 22 at 0° F crystallization point, necessary

concentration of glycol is either 32.5% by weight or 30% by

volume. Next, determine glycol flow rate:

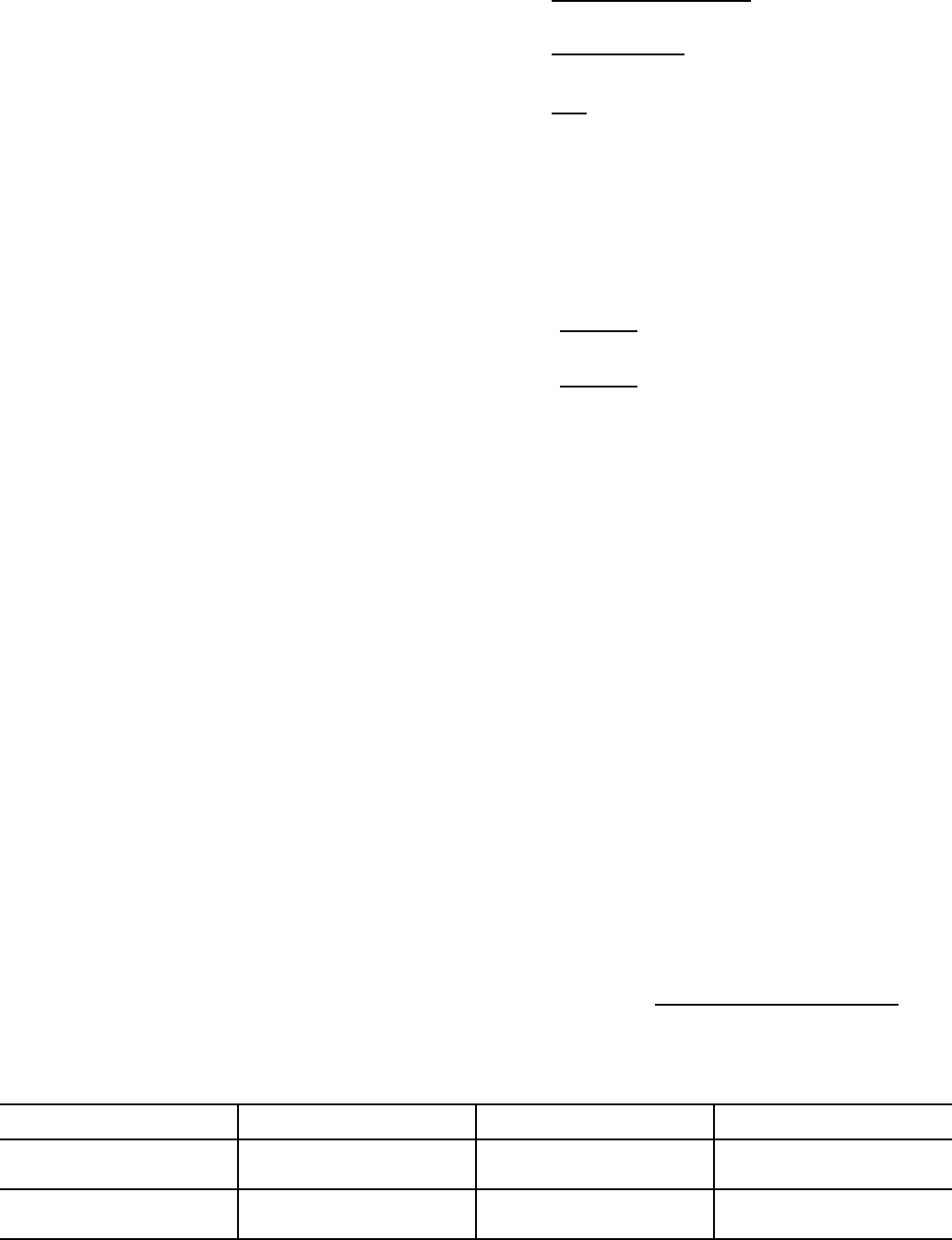

Table 32 — Condenser Water Circuiting

LF =

THR

SDT – 1.5 line loss – EWT

=

153

(105.8 – 1.5) – 85

=

153

= 7.9

19.3

Rise =

THR x 24

Gpm

=

153 x 24

= 12.2 degrees

300

Glycol Flow Rate =

THR (tons) x Glycol Factor (GF)

Rise

WATER CIRCUITING

ARRANGEMENTS

CONDENSER SIZE

CONDENSER

CHARACTERISTICS

NORMAL USE

Double Circuit

4 Passes

3 Passes

5F20, 5F30

5F40, 5F60

All 09RH

High Water Quantity

Low Pressure Drop

Cooling Tower

Single Circuit

8 Passes

6 Passes

5F20, 5F30

5F40, 5F60

All 09RH

Low Water Quantity

High Pressure Drop

City or Well Water