22

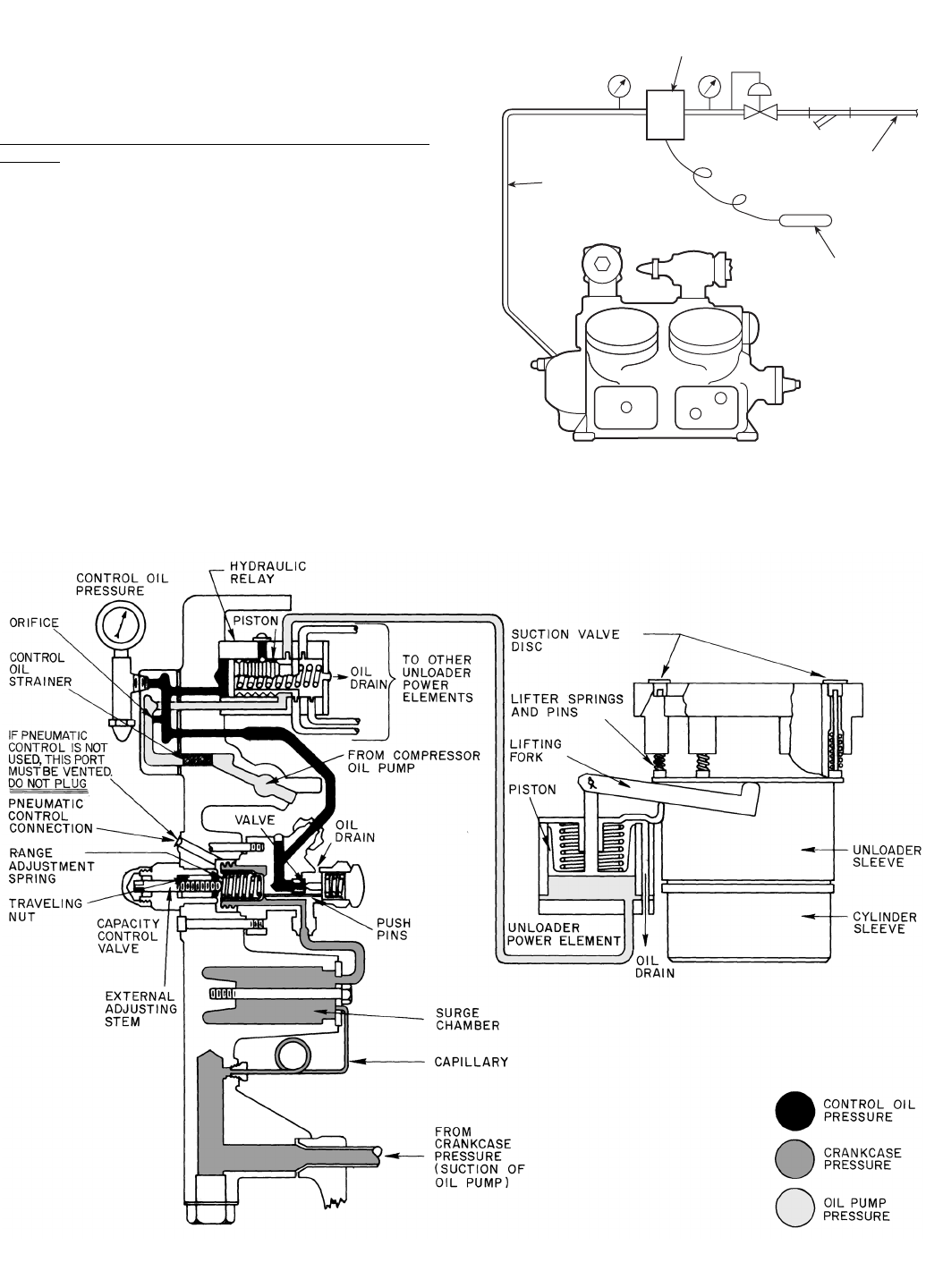

5H120, 5H126 CAPACITY CONTROL (Fig. 8) — This ca-

pacity control system is slightly different from the system on

5F40 through 5H86 compressors. Unloaded starting and capac-

ity reduction is obtained by holding open the suction valves of

a number of cylinders. For capacity control purposes, a

suction-pressure-actuated capacity control valve pilots a

hydraulic relay that loads or unloads cylinders in pairs.

Major Difference from the 5F40 through 5H86 Capacity

Control:

1. The hydraulic relay design provides a wider pressure

differential between cylinder cut-in and cutout points.

The relay is a small, easily removed cartridge rather than

an integral part of pump end cover.

2. The surge chamber on 5H120 and 5H126 is an integral

part of the bearing head casting.

PNEUMATIC COMPENSATION OF COMPRESSOR

CAPACITY CONTROL — Adding a control air line to the

external pneumatic control connection permits pneumatic

resetting of the control point in accordance with changes in

operating conditions. Each pound of change in air pressure

resets the control one pound in the same direction. Thus, a one-

pound rise in air pressure will cause unloading to begin at a

suction pressure one pound higher than the original control

point, etc. Figure 9 shows a typical pneumatic control arrange-

ment. All components and installation instructions are field

supplied.

Fig. 8 — Capacity Control — 5H120, 5H126

CONTROL

AIR

SENSING

BULB

3 TO 15 PSI

SIGNAL TO

COMPRESSOR

PNEUMATIC CONTROLLER

OUTPUT TO INCREASE ON

DECREASE IN CONTROLLED

TEMPERATURE

Fig. 9 — Pneumatic Compensation