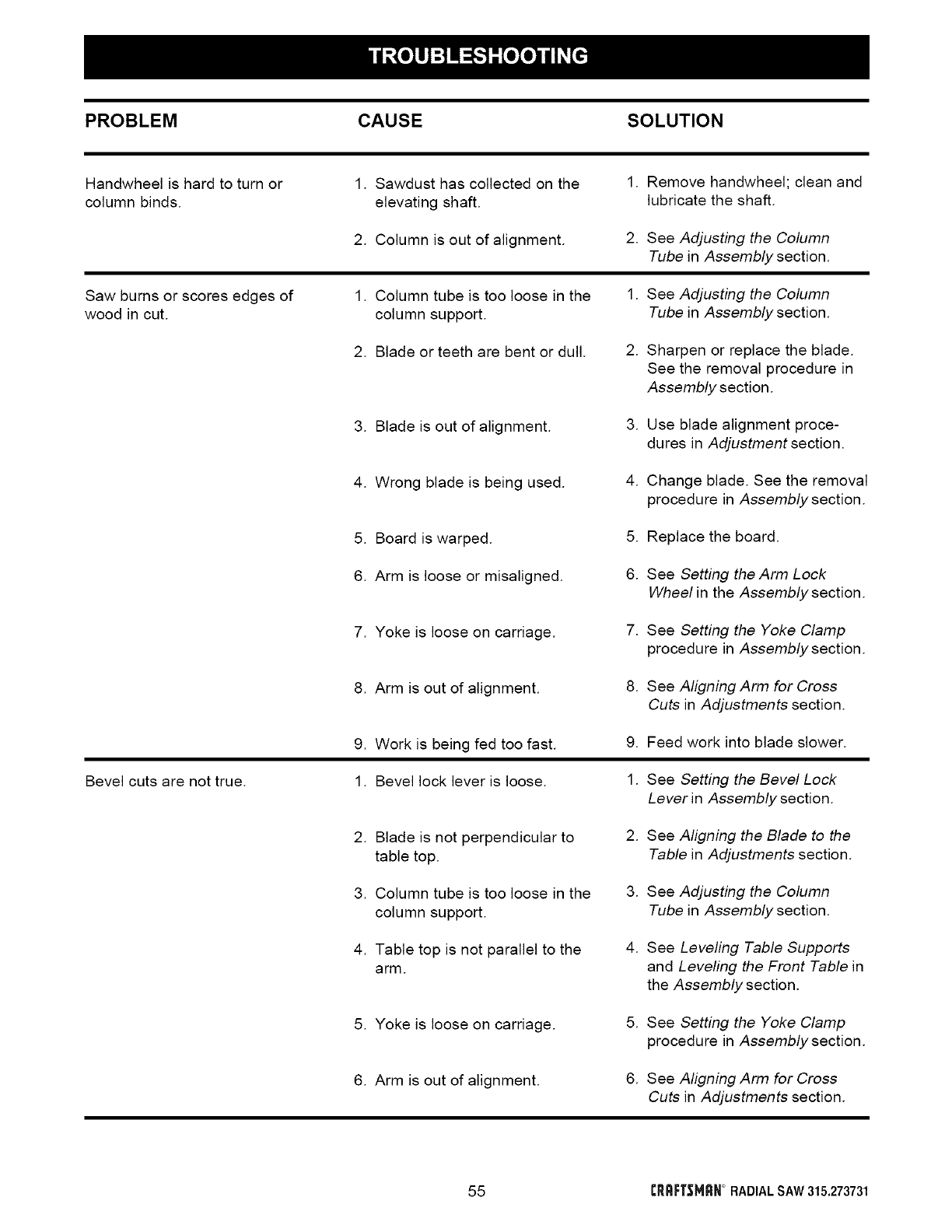

PROBLEM CAUSE SOLUTION

Handwheel is hard to turn or 1. Sawdust has collected on the 1.

column binds, elevating shaft.

Saw burns or scores edges of

wood in cut.

Bevel cuts are not true.

2. Column is out of alignment. 2.

1. Column tube is too loose in the

column support.

2. Blade or teeth are bent or dull. 2.

3. Blade is out of alignment. 3.

4. Wrong blade is being used. 4.

5. Board is warped. 5.

6. Arm is loose or misaligned. 6.

7. Yoke is loose on carriage. 7.

8. Arm is out of alignment.

.

9. Work is being fed too fast. 9.

1. Bevel lock lever is loose. 1.

2. Blade is not perpendicular to 2.

table top.

3. Column tube is too loose in the 3.

column support.

4. Table top is not parallel to the 4.

arm.

5. Yoke is loose on carriage. 5.

6. Arm is out of alignment.

.

Remove handwheel; clean and

lubricate the shaft.

See Adjusting the Column

Tube in Assembly section.

See Adjusting the Column

Tube in Assembly section.

Sharpen or replace the blade.

See the removal procedure in

Assembly section.

Use blade alignment proce-

dures in Adjustment section.

Change blade. See the removal

procedure in Assembly section.

Replace the board.

See Setting the Arm Lock

Wheel in the Assembly section.

See Setting the Yoke Clamp

procedure in Assembly section.

See Aligning Arm for Cross

Cuts in Adjustments section.

Feed work into blade slower.

See Setting the Bevel Lock

Lever in Assembly section.

See Aligning the Blade to the

Table in Adjustments section.

See Adjusting the Column

Tube in Assembly section.

See Leveling Table Supports

and Leveling the Front Table in

the Assembly section.

See Setting the Yoke Clamp

procedure in Assembly section.

See Aligning Arm for Cross

Cuts in Adjustments section.

55 CRRFTSMRN_ RADIALSAW315.273731