Troubleshooting

309298J 33

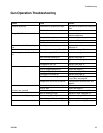

Gun Operation Troubleshooting

Problem Cause Solution

Excessive spray fog. Atomization air pressure too high. Decrease air pressure as low as pos-

sible.

Fluid too thin. Increase viscosity.

“Orange Peel” finish. Atomization air pressure too low. Increase air pressure; use lowest

pressure necessary.

Spray tip (4) too large. Use smaller tip; see page 51.

Poorly mixed or filtered fluid. Remix or refilter fluid.

Fluid too thick. Reduce viscosity.

Fluid leaks from the fluid packing

area

Worn fluid needle packings or shaft. Replace fluid needle assembly (8);

see page 41.

Air leaks from the air cap Worn piston stem o-rings (34e, 34f). Replace; see page 42.

Fluid leakage from the front of the

gun

Worn or damaged fluid needle (8). Replace; see page 41

Worn fluid seat housing (5). Replace; see page 37.

Loose spray tip (4). Tighten retaining ring (1); see page

37.

Damaged tip seal (4a). Replace; see page 37.

Gun does not spray Low fluid supply. Add fluid if necessary.

Dirty or clogged spray tip (4). Clean; see page 37.

Damaged spray tip (4). Replace; see page 37.

Damaged fluid needle (8). Replace; see page 41.

Piston (34) not actuating. Check cylinder air. Check piston

u-cup (34d); see page 48.

Actuator arm (29) is out of position. Check actuator arm and nuts. See

page 43.

Paint buildup on air cap Atomization air pressure too high. Reduce.

Dirty air cap. Clean; see page 37.

Air leaks from manifold Manifold is not tight. Tighten manifold screws (106).

Worn or missing o-rings. Replace o-rings. See page 43.

Fluid doesn’t shut off properly. Seat housing (5) too tight. Replace; see page 37.

Fluid buildup on fluid needle (8). Replace needle; see page 41.

Piston sticking. Clean or replace o-rings. See page

43.