G0459 12" Drum Sander

-33-

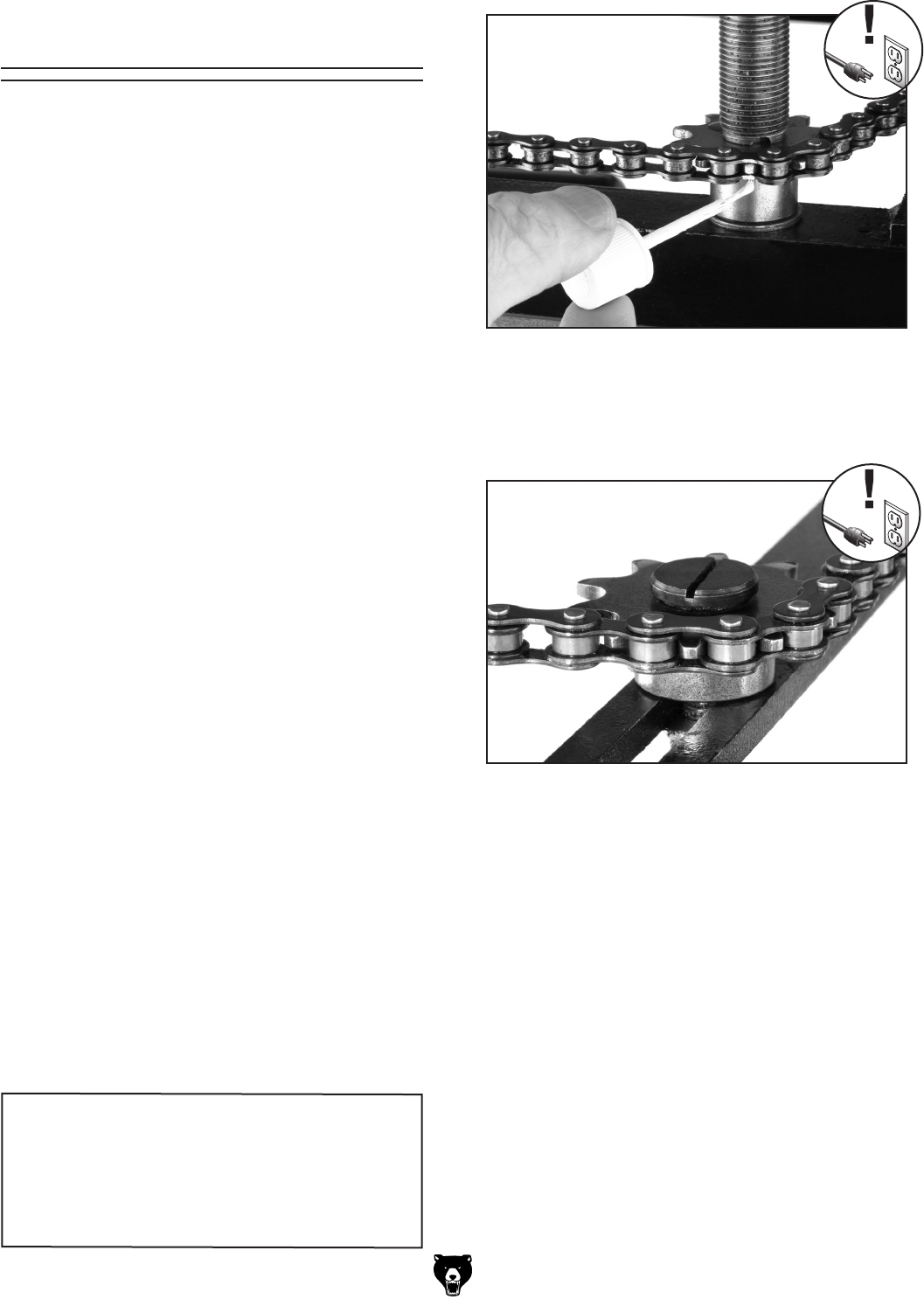

5. Loosen the chain by loosening the hex nut on

the bottom of the idler roller sprocket shown

in Figure 38.

Figure 37. Marking sprocket tooth and chain.

Tools Needed: Qty

Hex Wrench 6mm ..............................................

1

Wrench/Socket 12mm .......................................

1

Chalk, Correction Fluid, or Paint .......................

1

Phillips Head Screwdriver #2 ............................

1

Flat Head Screwdriver .......................................

1

The table lift screws are connected by a chain

and driven by the crank handle. (When the chain

is removed from a sprocket on one of the lift

screws, that lift screw can adjust that portion of

the table up/down independently to assist in set

-

ting the table parallel to the drum.)

Adjusting the table lift screws will only be neces

-

sary if you need to adjust the drum height more

than allowed at the pillow block bearing adjust

-

ments, or if you have removed the table or chain

(see Page 37

) during a service procedure and

you need to reset the drum parallel to the table

.

Each complete tooth rotation on the sprocket

represents 0.007" or .18mm of table elevation

movement. For example, if the rear of the table

was

0.007" low, rotate both rear table lift screws

to the next sprocket tooth in the same chain posi

-

tion. You can easily rotate the sprockets from

the top of the table lift screws with a flat head

screwdriver.

To adjust the table lift screws:

1. DISCONNECT POWER TO THE SANDER!

2. Open the right side and front panels.

3. Raise the table up to at least the 1" mark on

the height scale.

4. At the lift screw that needs to be adjusted,

mark the end of a sprocket tooth and the

chain hole where that tooth is meshed, as

shown in

Figure 37.

Table Lift Screws

6. Carefully move the chain off of only the

marked sprocket.

7. Keep track of the marked chain hole and

rotate the sprocket the necessary number of

teeth away from the marked one to meet the

difference in height needed.

8. Fit the chain back over the sprocket, making

sure the new sprocket tooth is inserted into

the marked chain hole.

9. Re-tension the chain and check the new

height setting.

10. Repeat Steps 5–9 as needed until the table

height is parallel to the drums in all four cor

-

ners, tighten the idler sprocket and calibrate

the scale pointer.

Figure 38. Idler roller sprocket.

NOTICE

Marking the chain and sprocket locations

will save you a substantial amount of time

when you reinstall the chain. Make sure you

have done this before removing the chain.