G1015 Knife Belt Sander/Buffer -10-

SECTION 4: ASSEMBLY

Mounting Base

All die-cut metal parts have a sharp edge

(called “flashing”) on them after they are

formed. This is generally removed at the

factory. Sometimes a bit of flashing might

escape inspection, and the sharp edge may

cause cuts or lacerations when handled.

Please examine the edges of all die-cut

metal parts and file or sand the edge to

remove the flashing before handling them.

Failure to do so could result in injury.

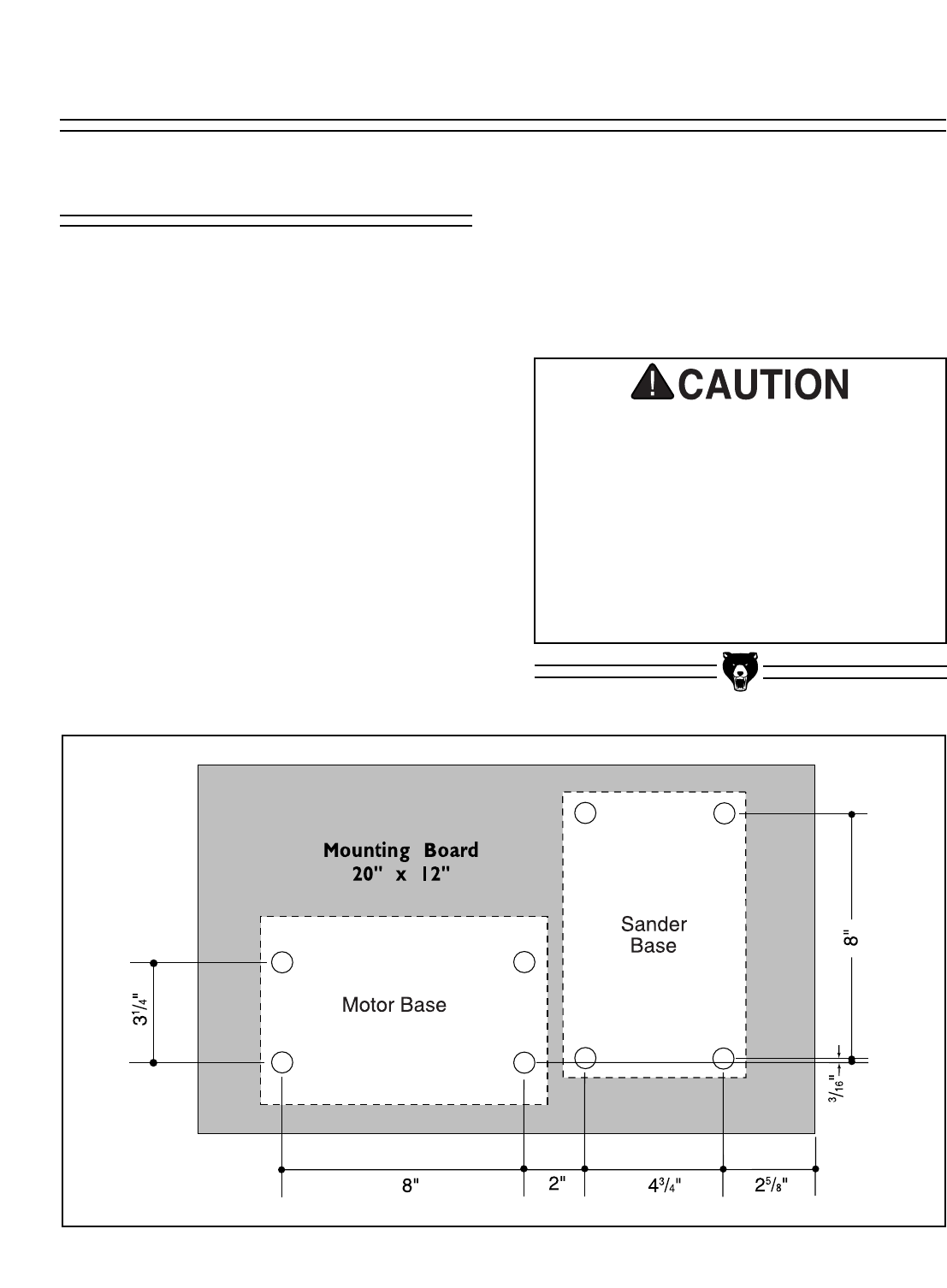

Figure 3. Bolt pattern for base. All dimensions are measured at hole centers.

Before assembly can be completed, the Model

G1015 motor base and belt sander base must

both be mounted to a bench, or a wooden base,

to provide the stability necessary for safe opera-

tion. If you choose to create a wooden base for

more portable operation, we recommend laminat-

ing two 20" x 12" x

3

⁄4" pieces of plywood togeth-

er, or use 1'' thick MDF (medium density fiber-

board). For a wooden base, you may also want to

countersink the underside to accommodate the

hex nut and washers so the base will sit flat.

The layout in Figure 3 provides the recommend-

ed pattern for both motor base and sander base

mounting. Because of variation in the castings,

you may want to drill only the holes for the motor

base, then drill the sander base holes later after

you have mounted the pivot arm assembly.

Holes should be drilled for

5

⁄16" lag bolts (

1

⁄4" pilot

hole) or

5

⁄16" machine bolts (

1

⁄2" diameter will allow

some minor adjustment). Mounting hardware is

not included. If using machine bolts, use a lock

washer secured between a flat washer and the

nut to ensure the bolt will not loosen during oper-

ation. Continue with the mounting procedure as

described in the following pages.