-17- G1015 Knife Belt Sander/Buffer

SECTION 6: Operations

Before you put your Belt Sander/Buffer into use,

give it a quick inspection. Before inspecting,

ensure that the machine is switched off and dis-

connected from its power source.

1. Are all mounting fasteners tight?

2. Is the sanding belt properly tracked and

tensioned?

3. Rotate the drive wheel slowly by hand.

Look and listen for any scraping noises or

anything that impedes smooth movement.

Make appropriate adjustments before

attempting to run the machine.

4. If the sander appears to be free of prob-

lems that might affect its operation, plug it

in to its power source and start the

machine. Be sure to keep a finger on the

OFF button, just in case of a problem with

the machine. Run the machine briefly to

allow inspection of belt tracking.

5. Turn off the machine, disconnect it from its

power source, and re-inspect for loose fas-

teners. If the tracking is not correct, refer to

the tracking adjustment guidelines in the

Adjustments section.

Never use the Model G1015 for applications

other than those for which it was made. DO

NOT overload the machine or use excess

force when sanding. Severe personal

injury, damage to the machine, or damage

to your workpiece could occur.

Test Run

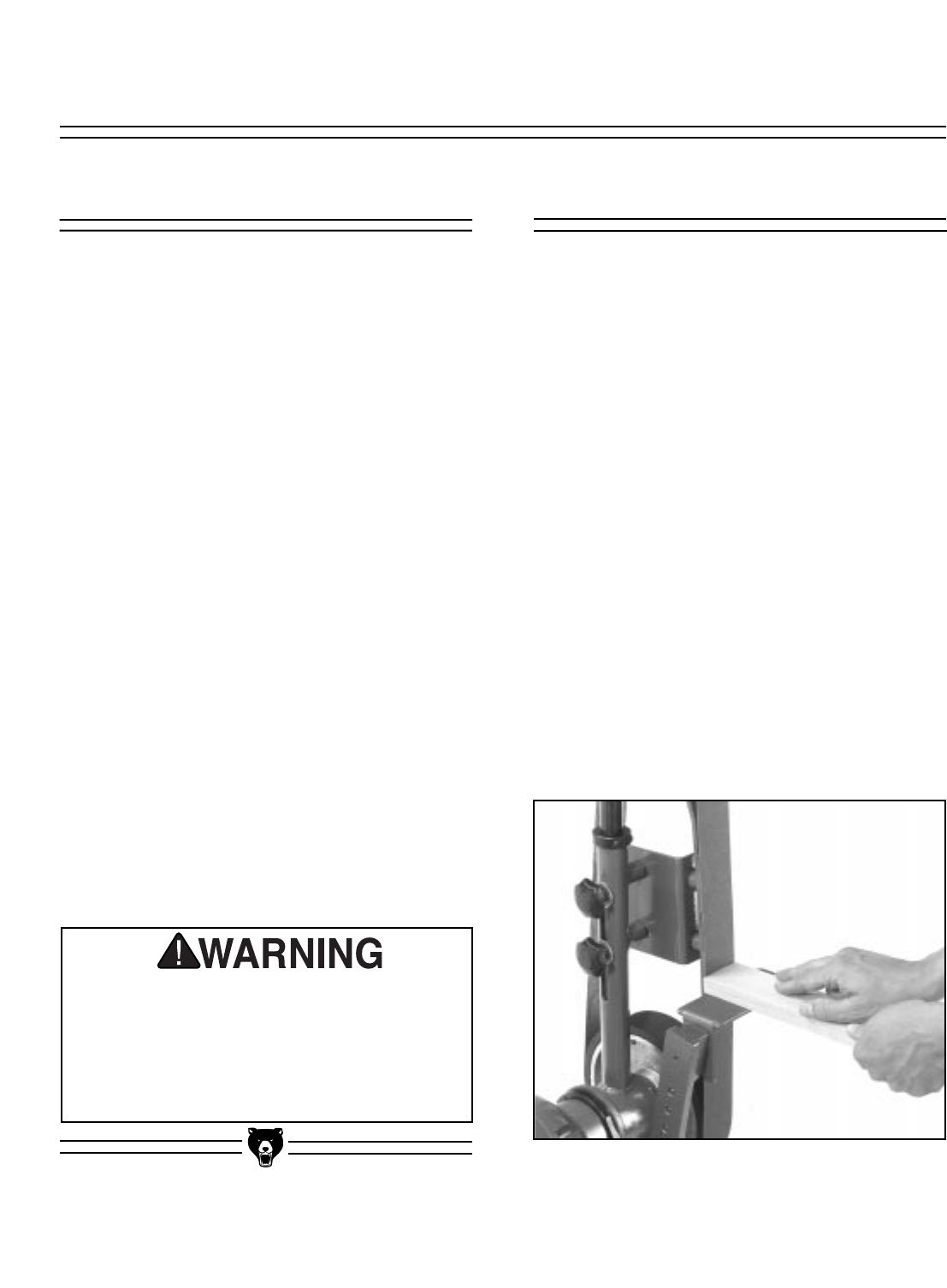

Figure 16. Belt sanding wood.

The sanding belt can be used to sand wood or

metal. We recommend aluminum oxide sanding

belts for wood and silicon carbide for metal.

Always be sure the belt is properly installed so

the direction of rotation arrows follow the direction

of rotation of the drive wheel. This keeps the

seam in the belt oriented so it will not catch on the

workpiece. The 2" belt width, used in conjunction

with the graphite-faced sanding shoe provides an

excellent surface for angular sanding or polish-

ing.

The tool rest should always be adjusted so it is no

more than

1

⁄8" away from the belt surface. This

helps to assure that nothing can get trapped

between the rest and the belt.

Figure 16 shows a typical wood sanding opera-

tion with the tool rest perpendicular to the belt

surface. The tool rest can be checked for square-

ness to the belt by placing a machinist’s square or

try square on the tool rest and adjusting the angle

of the rest.

Belt Sanding