-19- G1015 Knife Belt Sander/Buffer

For buffing and polishing, Grizzly offers a broad

selection of buffing wheels and polishing com-

pounds that are very well suited for use with the

Model G1015. Please refer to our current catalog.

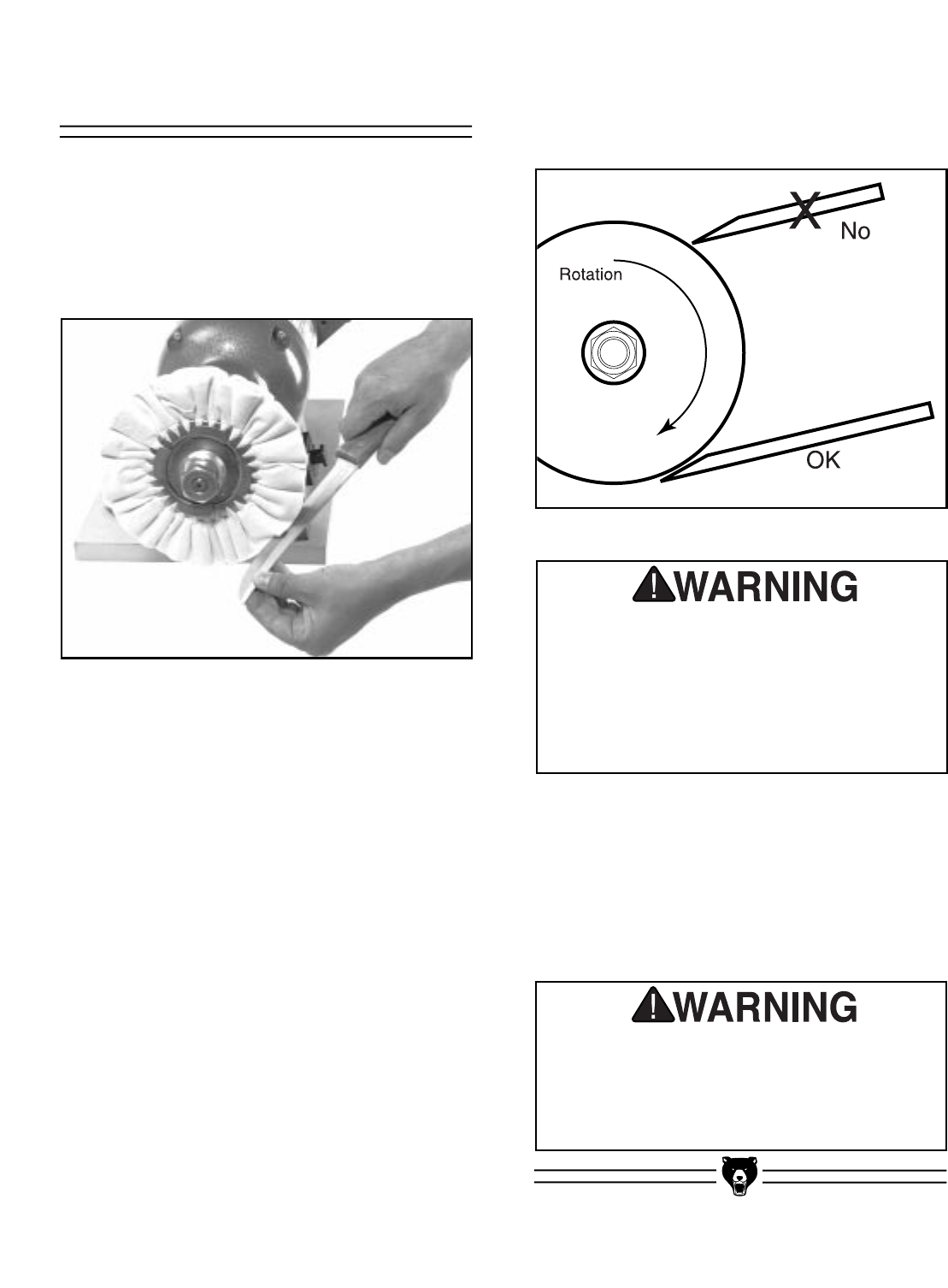

The auxiliary motor shaft arbor accepts buffing

wheels with a

5

/8'' bore. See Figure 20.

Buffing & Polishing

Pieces of the buffing wheel or buffing com-

pound can be expelled from the machine at

extremely high speeds. Always wear ANSI-

approved safety glasses to avoid injury to

your eyes.

Never introduce a sharp edge of a work-

piece into the direction of rotation.

Always work with the rotation direction.

Workpieces can be pulled from your grasp

if forced into the wheel, or if too much pres-

sure is used while buffing. Serious person-

al injury could result.

Figure 20. Optional buffing wheel attached.

Figure 21. Buffing on the bottom of the wheel.

6. Firmly grasp the item to be polished with

both hands. Lightly and evenly move the

item across the face of the wheel until the

surface is polished. Use extra care when

polishing plated materials. Over-buffing can

completely remove plating when exposed

to the abrasive wheel for too long.

To buff and polish:

1. Make sure the machine is off and the power

cord is unplugged. Remove the left-handed

nut at the end of the shaft.

2. Sandwich an optional buffing wheel

between two wheel flanges and slide onto

the shaft.

3. Tighten the nut with one hand while holding

the shaft with the other. The left-handed

rotation will ensure that the nut stays tight

during operation.

4. With a brand new buffing wheel it is neces-

sary to charge the wheel with compound

before the first use. Follow the directions

which come with the buffing wheel and

compound.

5. If facing the front of the machine, buffing

and polishing should be done on the bot-

tom of the wheel. See Figure 21.