-15- G1015 Knife Belt Sander/Buffer

SECTION 5: Adjustments

Belt Tension

The Model G1015 features a self-tensioning

mechanism which automatically applies tension

to the sanding belt. If you are using a different

length belt than the one supplied (72'') you will

need to adjust the distance between the two

wheels. To adjust the tensioning:

1. Pull down the tensioning knob and remove

the sanding belt.

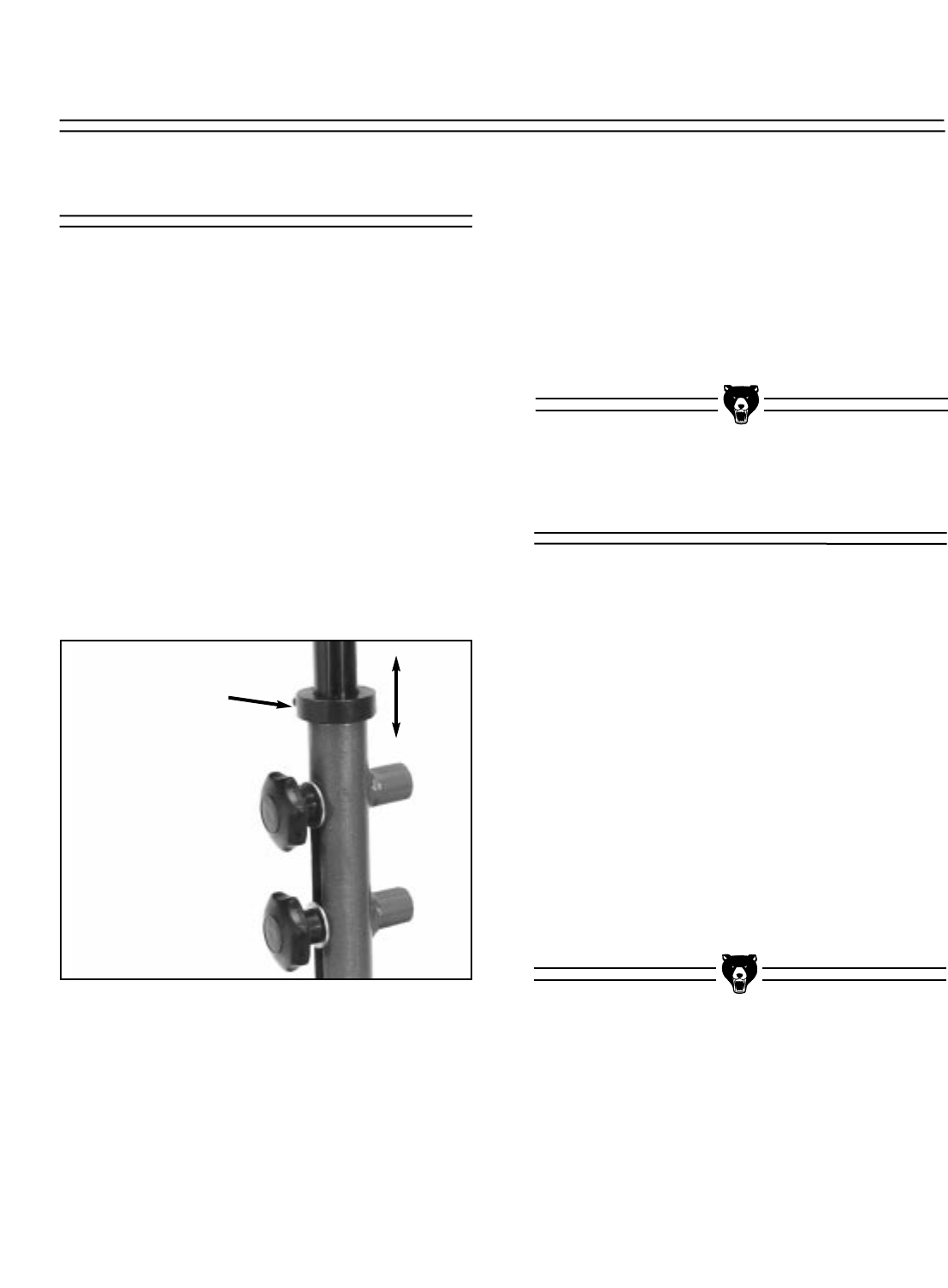

2. Loosen the hand knobs on the pivot arm

and raise or lower the upper assembly to

increase or decrease the distance between

the wheels. See Figure 13. You may need

to loosen the stop collar to allow the neces-

sary movement.

Figure 13. Length adjustment for upper arm.

Stop Collar

3. Replace the sanding belt onto the wheels

and inspect for tension. Be sure the track-

ing adjustment is set so the upper wheel

shaft is almost perpendicular. The belt

should deflect approximately

1

⁄2'' inch when

you press against it. Check it on the back

loop of the belt where it comes up from the

drive wheel to the upper wheel. This way

the deflection will not be affected by the

sanding shoe. Repeat step 2 if needed.

Tool Rest

The tool rest should be adjusted so it is posi-

tioned in front of the sanding belt shoe’s graphite

surface. The clearance between the tool rest and

the belt should be no more than

1

⁄8'' to ensure that

nothing can become trapped between the belt

and the rest. The angle of the rest relative to the

belt surface can be adjusted by loosening the cap

screw, adjusting the rest angle and re-tightening

the cap screw.

The height of the tool rest can also be adjusted

by removing the two (2)

5

⁄16" - 18 x 1

1

⁄4" cap screws

holding the two halves of the tool rest bracket

together. Selection of different hole combinations

results in varying lengths. The tool rest should be

set high enough so that it is located over the

graphite pad portion of the sanding shoe.