-11-

Motor

Place the motor over its mounting holes as

shown in Figure 4 and secure with

5

⁄16" machine

bolts or

5

⁄16" lag bolts.

Figure 4. Motor secured to base.

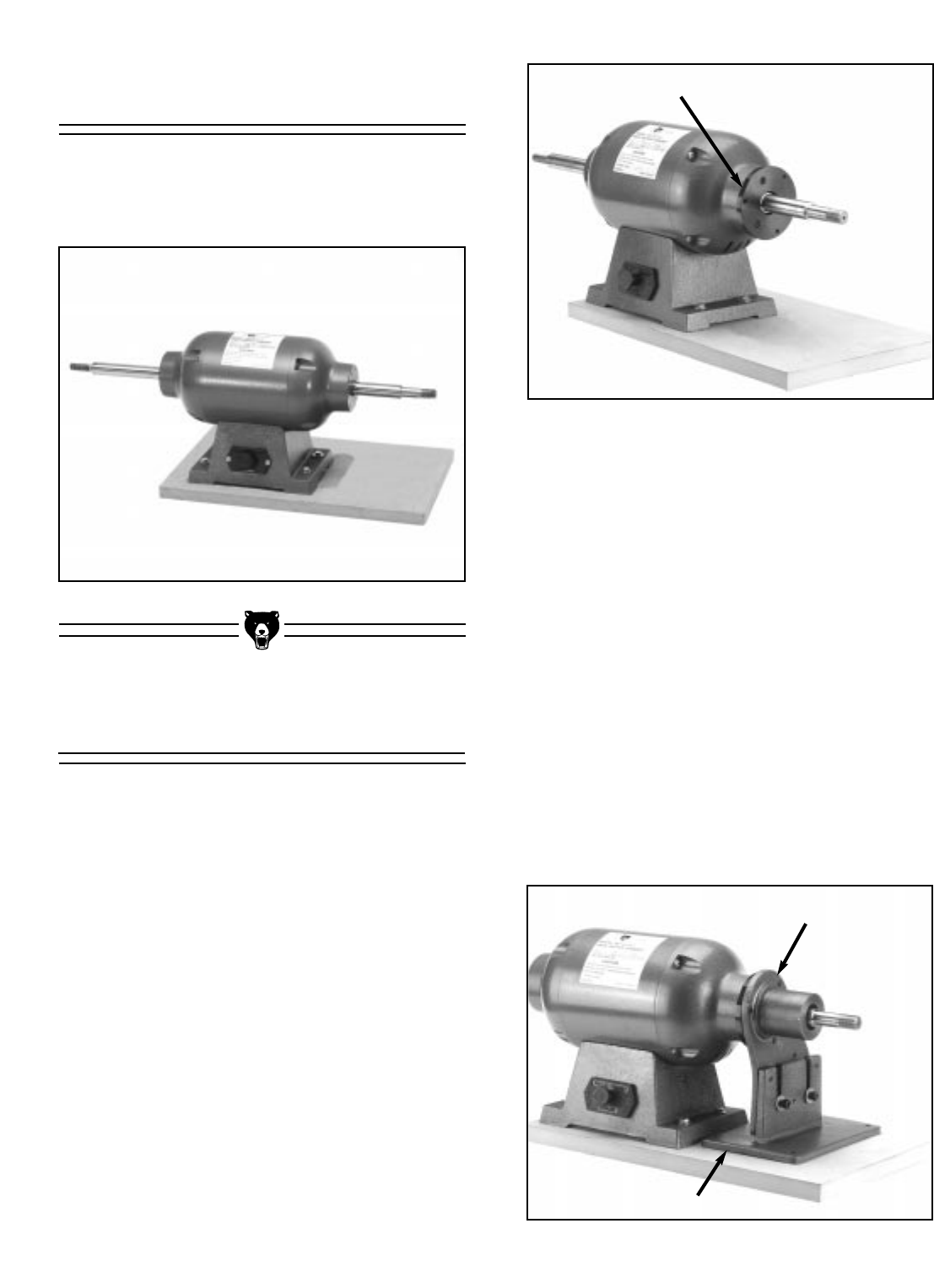

Pivot Arm

1. Secure the round mounting spacer to the

end bell of the motor using three (3)

1

⁄4 - 20

x

1

⁄2'' cap screws. See Figure 5. Make sure

the cap screws go into the countersunk

side of the spacer plate. The flat edge of

the spacer should be positioned at the 10

o’clock position if you are looking directly at

the end of the motor.

Figure 5. Mounting spacer to end bell.

Flat Edge

Figure 6. Bracket assembly attachment.

2. Back off the two setscrews at the bottom of

the pivot arm and remove it from the pivot

arm bracket. This is a tight fit and it may

require moving the arm back and forth to

get it to come off of the bushing. Assemble

the pivot arm bracket to the mounting

bracket as shown in Figure 6. Align the

open ended slots with the three (3)

5

⁄16" - 18

x 1" cap screws which are already threaded

into place on the two brackets. Leave these

cap screws loose for now. If there are

setscrews installed on the two brackets,

these may be removed, they are no longer

used for the current method of assembly.

Slide this assembly over the shaft on the

right hand side of the motor. Use three (3)

1

⁄4'' - 20 x

1

⁄2'' cap screws to attach the pivot

arm bracket to the spacer.

Pivot Arm

Bracket

Mounting Bracket

G1015 Knife Belt Sander/Buffer