G5959Z 12" Left-Tilting Table Saw -5-

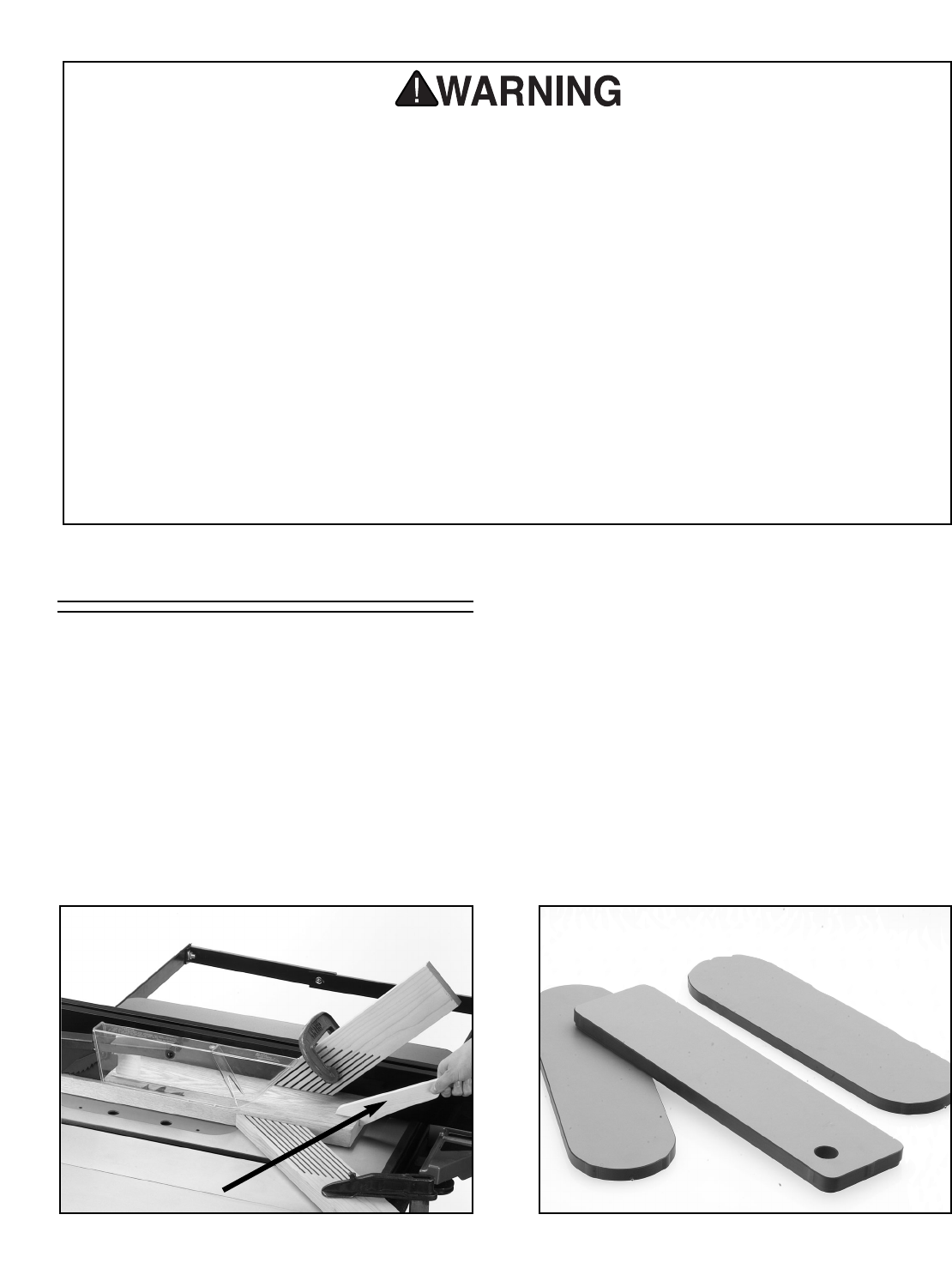

Push Sticks

The use of push sticks (shown in Figure 1), par-

ticularly when cutting small or narrow workpieces,

provides a double benefit for saw operators. The

push stick provides added leverage, enabling the

operator to keep the workpiece firmly supported

against the fence and table. At the same time, the

push stick keeps the operator’s hand safely away

from the rotation of the saw blade. See the tem-

plate at the end of the manual for construction

details, or purchase one from the Grizzly catalog.

Zero Clearance Table Inserts

Ideal for use when ripping thin strips or making

bevel cuts, these prevent tearout and jammed

blades by supporting material close to the blade.

Use the standard table insert as a template when

creating additional inserts from wood or plywood.

Blade slot inserts can be custom cut for specific

blade angles by raising the running blade into an

uncut insert at the angle you desire. Be sure to

make an additional slot for the blade splitter. We

also carry a wide selection of table inserts (shown

in Figure 2) in the Grizzly catalog. Be sure to hold

the insert firmly in place with a piece of wood

when creating slots. Never hold the table insert

with your hand while cutting new slots.

Safety Accessories

Statistics prove that most common accidents among table saw users can be linked to kickback.

Kickback is typically defined as the high-speed expulsion of stock from the table saw toward its

operator. In addition to the danger of the operator or others in the area being struck by the fly-

ing stock, the operator’s hands may be forced into the blade during the kickback. The following

can help minimize kickbacks.

1. Use your blade guard and splitter.

2. Never for any reason place your hand behind the blade. Should kickback occur, your hand will

be pulled into the blade.

3. Make sure the splitter and the blade are aligned.

4. Never use the fence as a guide for crosscutting.

5. Always use either the fence or the miter gauge to position and guide the work.

6. Use a pushstick or featherboard to maintain control of your workpiece.

7. Feed cuts through to completion.

8. Stand to the side when ripping.

9. Ensure your fence and miter slot are parallel to the blade.

If you do not clearly understand kickback and how it occurs, do not operate this table saw.

Figure 1. Push Stick.

Figure 2. Zero Clearance Table Inserts.