G9729 Combination Lathe/Mill

-25-

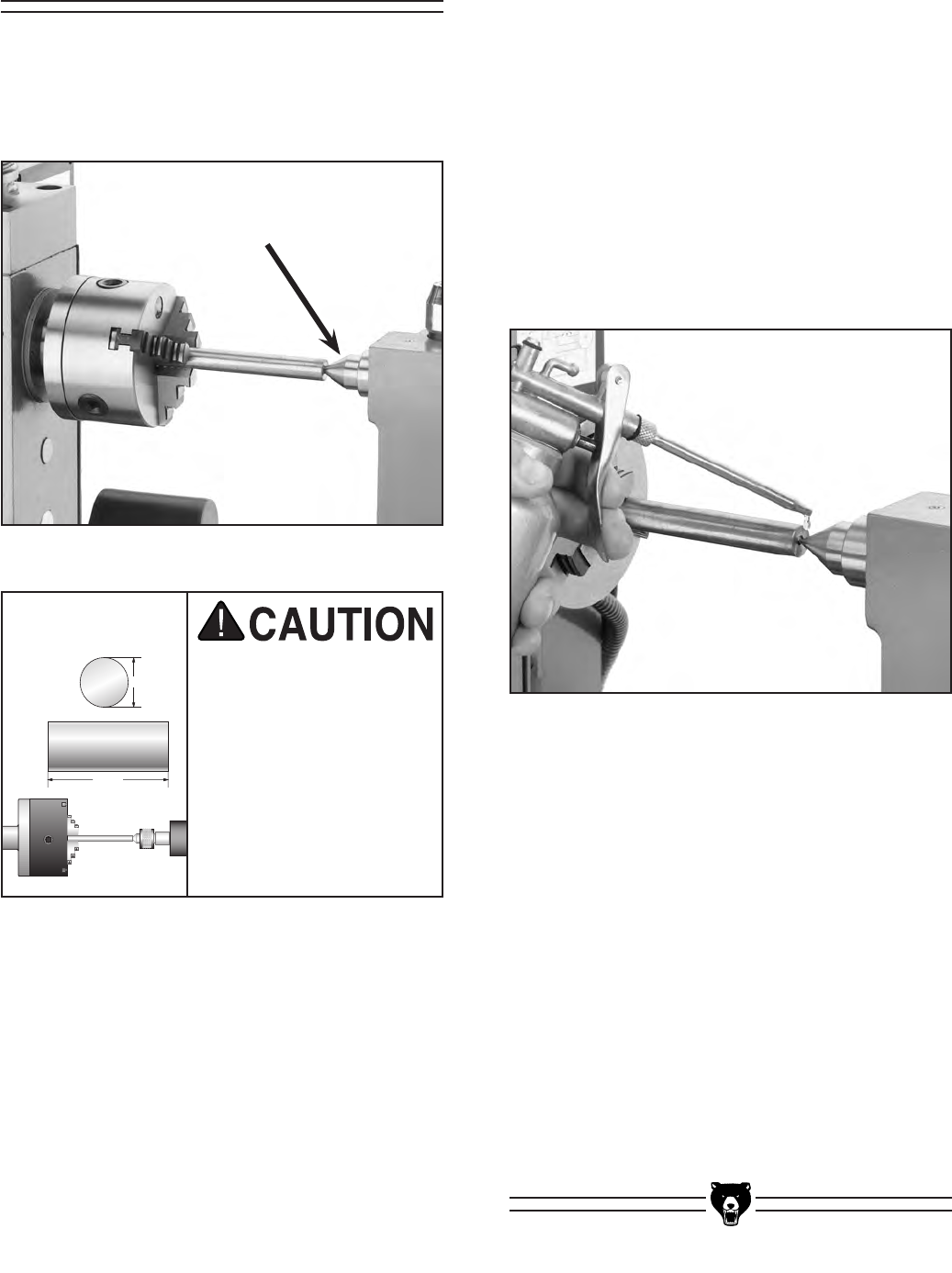

Dead Center

The dead center is used to support stock that

is too long to be supported by the chuck alone.

Stock protruding more than 2

1

⁄2 times its diameter

should be supported by a dead or live center.

The tailstock quill and the dead center have

a Morse Taper #3. Before assembling these,

ensure that the mating surfaces are very clean.

Clean the mating surfaces so they are free of dirt

and oil. These parts will last longer and remain

accurate when properly cleaned before assem-

bly.

Morse tapers will not interlock when dirt or oil

are present on the mounting surfaces.

Figure 16. Dead center installed in tailstock.

Figure 17. Oil center hole before seating the

dead center.

Always use a center to

support the end of any

workpiece that protrudes

out of the chuck further

than 2

1

⁄2 times its own

diameter. A workpiece

not supported this way

could bend suddenly

and cause serious per-

sonal

injury.

D

2

1

⁄

2

x D

Insert the end of the dead center into the tailstock

bore until it seats. The force of the dead center

contacting a mounted workpiece will fully seat the

taper when the handwheel is tightened.

When using a center, the tailstock quill should

protrude about

1

⁄2'' and not more than 1

1

⁄4'' out of

the tailstock body (Figure 16).

To

minimize wear and maximize smooth opera-

tion,

oil the tip of the dead center before seating

it in the workpiece as in Figure 17. Heat from fric-

tion

will reduce the life expectancy of the center,

and may cause chatter in the workpiece and spoil

the center hole.

To remove the dead center, back the tailstock

quill all the way into the tailstock casting by turn-

ing

the handwheel counterclockwise. The dead

center will pop out. Be sure to hold it before it

comes out, preventing the dead center from fall-

ing

and causing any damage to the lathe or the

dead center.

The dead center is used with the idea of achieving

a more accurate finished product while keeping

the spindle RPM low. Failure to do this will burn

up the dead center. For a slight bit of accuracy

loss and large gain in time, the live center can be

used. The live center has bearings letting the cen-

ter

and the workpiece rotate together, instead of

the workpiece rotating around the dead center.