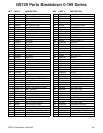

G9729 Combination Lathe/Mill

-55-

Symptom Possible Cause Possible Solution

Motor will not start.

1. Low voltage.

2. Open circuit in motor or loose connec-

tions.

3.

Faulty start capacitor.

1. Check power line for proper voltage.

2. Inspect all lead connections on motor

for loose or open connections.

3. Replace start capacitor.

Motor will not start; fuses or circuit break-

e

rs blow.

1. Short circuit in line cord or plug.

1. Repair or replace cord or plug for dam-

aged insulation and shorted wires.

Motor fails to develop full power (output

of motor decreases rapidly with decrease

in voltage at motor terminals).

1. Power line overloaded with lights, appli-

ances,

and other motors.

2. Undersized wires or circuits too long.

1. Reduce load on power line.

2. Increase wire sizes or reduce length of

the circuit.

Motor overheats. 1. Motor overloaded.

2. Air circulation through the motor

restricted.

1.

Reduce load on motor.

2. Clean out motor to provide normal air

circulation.

Table

hard to move. 1. Table locks are tightened down.

2. Chips have loaded up on bedways.

3. Bedways are dry and in need of lubri-

cation.

4.

Longitudinal stops are interfering.

5. Gibs are too tight.

1. Check to make sure table locks are

fully released.

2. Frequently clean away chips that load

up during milling operations.

3. Lubricate bedways and handles.

4. Check to make sure that stops are

floating and not hitting the center stop.

5. Loosen gib screw(s).

Breaking tools, cutters. 1. RPM and or feed rate is too fast.

2. Cutter getting too hot.

3. Taking too big of a cut.

1. Use tables to set correct RPM and feed

rates.

2.

Use cutting fluid or oil for appropriate

application.

3.

Lessen depth of cut and allow chips to

clear.

Workpiece

vibrates or chatters during

operation.

1.

Table locks not tight.

2. Spindle lock not tight.

3. Workpiece not securely clamped to

table or into mill vice.

4. RPM and feed rate too high.

1. Tighten down table locks.

2. Tighten spindle lock.

3. Check that clamping is tight and suf-

ficient

for the job. Make sure mill vice

is tight to the table.

4. Use appropriate RPM and feed for the

job.

L

oud repetitious noise coming from

machine.

1. Pulley set screws or keys are missing

or loose.

2. Motor fan is hitting the cover.

3. V-belts are defective.

1. Inspect keys and set screws. Replace

or tighten if necessary.

2. Adjust fan cover mounting position,

tighten fan, or shim fan cover.

3. Replace V-belts.

Bad surface finish. 1. Wrong RPM or feed rate.

2. Dull cutter or poor cutter selection.

3. Wrong rotation of cutter.

1. Adjust for appropriate RPM and feed

rate.

2.

Sharpen cutter or select a better cutter

for the intended operation.

3. Check for proper cutting rotation for

cutting tool.

Troubleshooting