-20-

Model T10687 (Mfg. Since 10/12)

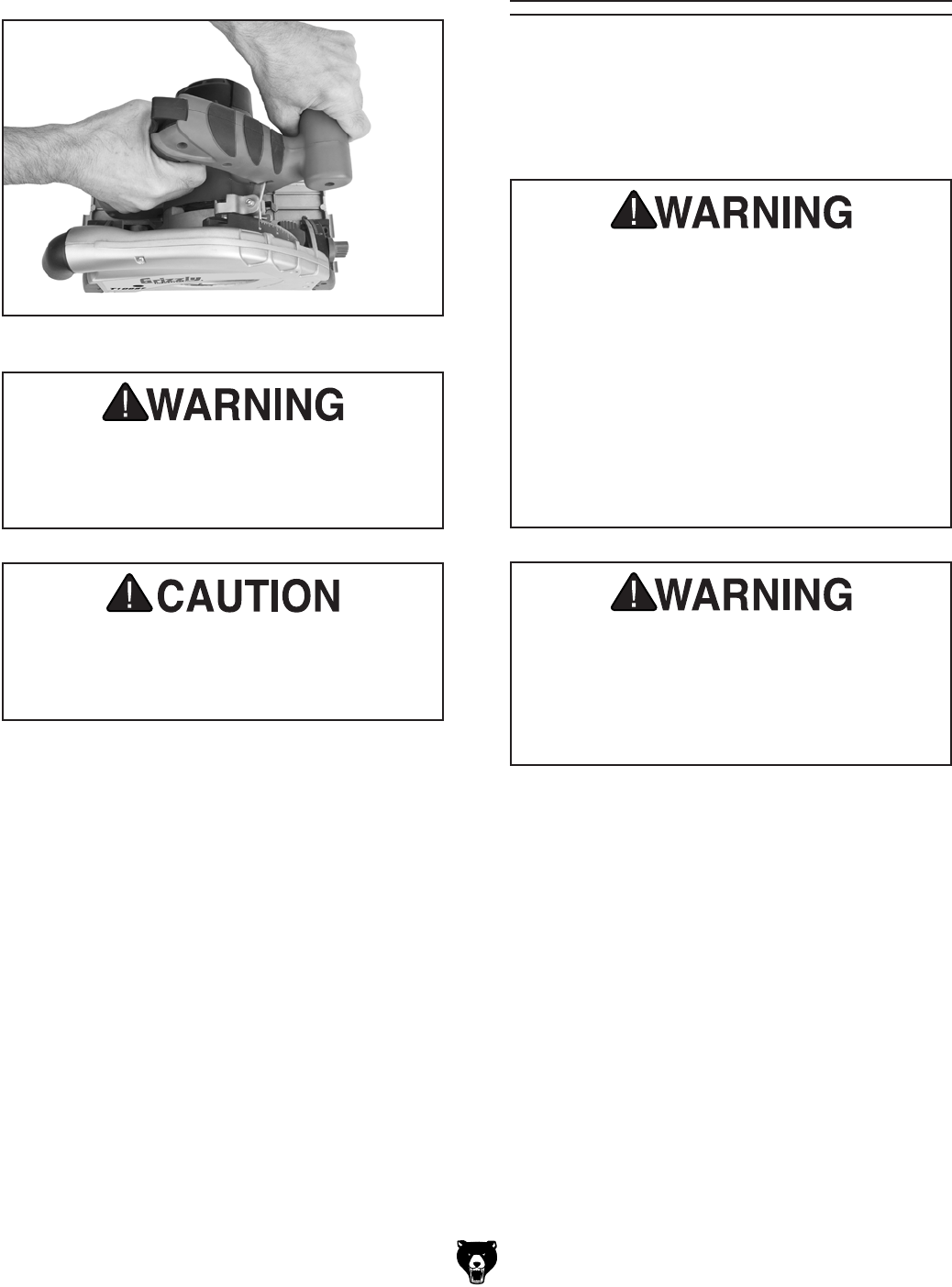

3. Hold the saw firmly with one hand on each

handle, as shown in Figure 18.

Plunge cuts are made by positioning the saw on

the workpiece so that the blade begins cutting as

soon as it is lowered. Plunge cuts work well for

removing an area within the workpiece without

sawing through the outer perimeter.

Making Plunge Cuts

Figure 18. Proper hand positions.

4.

Engage the plunge release and extend the

blade. To activate the saw, pull the power

trigger while holding the plunge release.

Note: Holding the power trigger alone will not

activate the saw. For power to be activated,

both the plunge release and the power trig-

ger must be pressed. After power has been

activated, the plunge release can be disen-

gaged.

5.

Move the saw forward over the workpiece in

an even, steady motion.

6.

When finished, release the power trigger and

allow the blade to come to a complete stop.

Return the saw to its upright position by lifting

up on the handle, allowing the blade to retract

and the saw to lock in place.

Let the saw reach full speed before contact-

ing the workpiece. Doing so will reduce the

risk of kickback, help provide the cleanest

cut, and reduce stress on the saw motor.

Keep fingers and hands away from the saw

blade and out of blade path during opera-

tion. Use clamps to hold the workpiece in

place if needed.

Making blind plunge cuts without checking

your cutting path for unseen objects could

result in injury from kickback, electrocution,

building damage or fire, gas explosions, or

death. Whenever making a blind plunge cut

into a standing structure (like a wall), always

check the cutting path for hidden wires,

nails, and other metal objects by thoroughly

scanning the area with an electric stud

finder or similar device. NEVER risk a blind

plunge cut without first checking your cut-

ting path.

Whenever operating the saw in the vicinity

of live wires, always wear insulated gloves.

Avoid unintentionally grounding yourself

when operating the saw by being in contact

with electrically-conductive materials (metal

pipes, appliances, etc.).

To make plunge cuts:

1.

Mark the desired start and stop cut-points on

your workpiece.

2. Set the depth of cut (as described in the

Setting Cutting Depth section on Page 19).