SAFETY INSTRUCTIONS

Manoeuvring

General

• If several machines are used at the same workplace

there is a risk of mixing up the remote controls.

Switch on the current to the remote control and

the machine. Press the horn to see which machine

is connected to the remote control. The machine

will beep and fl ash three times. Do not activate the

remote control before you have ensured that the

correct machine is being operated.

• Wait until the remote control has been turned off

and the motor has stopped before you enter into

the machine’s risk area.

• Never leave the machine unsupervised with the

motor running.

• The machine can overturn during work. During op-

eration the machine must be positioned as level as

possible and the outriggers must be fully extended.

• In some cases it can be diffi cult to determine which

end of the machine is the front and which is the

rear. Look at the direction markings on the sides of

the machine’s tracks to avoid incorrect operation.

Outriggers

• When the outriggers are folded, the arm must be

retracted to minimize the risk of the machine over-

turning.

• The machine’s outriggers can leave the ground,

especially when working with a hydraulic hammer or

bucket. The higher the machine rises the greater the

load the rest of the support mechanism is subject

to.

• When working with a hydraulic hammer there is an

increased risk of the machine tipping or landing with

a large force on the outrigger on impact. Take this

risk into account and institute appropriate safety

measures to avoid any personal injury or mechanical

damage.

Rotation function

• If there is a breakdown in the machine’s rotation

mechanism the machine’s upper part may rotate

freely, potentially causing personal injury or me-

chanical damage. Keep your distance.

• The machine is most stable when working directly

forwards or backwards. When the machine’s upper

part rotates to the side, the outriggers should be

down and the arm system manoeuvred so that it is

as close to the ground as possible.

• In some cases it can be diffi cult to predict the

direction of rotation. Operate the turning motion

carefully until you have apprehended the direction

of rotation.

Arm system

• Do not use the arm system and the rotation func-

tion for striking, demolishing or scraping.

• Do not work with the arm if the machine’s outrig-

gers are folded. The outriggers provide stability

and reduce the risk of the machine tipping.

• When the arm system’s reach is being used, the

load increases as does the risk of tipping. Posi-

tion the machine as close to the working object as

possible.

• Never use the telescopic arm to press the tool

against the working object.

• Do not secure the machine to fi xed objects, e.g.

walls, to increase the force on the working object.

Both the machine and the tool can be subject to

overloading.

• Do not work with the machine’s cylinders in the

inner or outer end positions to avoid overloading.

Leave a few centimetres to the maximum position.

The hydraulic fl uid then has a greater capacity to

alleviate impacts and vibrations.

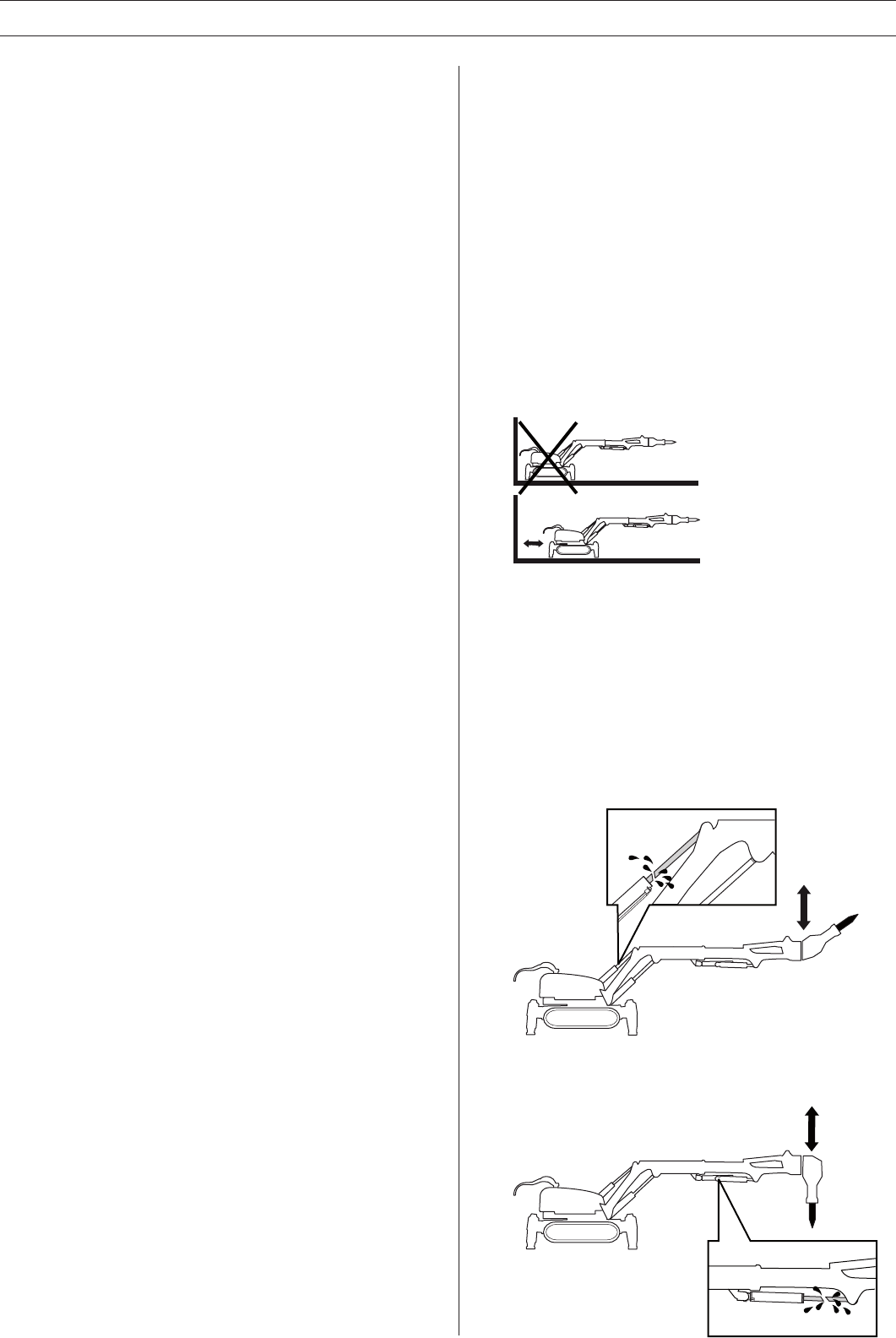

• There are two working positions that put a lot of

strain on individual cylinders.

Cylinders 1 and 2 are in their outer positions and

the hammer is working in the upward direction.

Never operate the cylinders to their end positions.

Cylinder 3 is in its outer position and the hammer is

working in the downward direction. Never operate

the cylinders to their end positions.

10 - English