Level check

Position the machine on a fl at surface. Clean the

component before it is opened for reading or fi lling

in order to prevent dirt entering the system. If the oil

level is low, refi ll with the type and quality as per the

’Hydraulic fl uid and lubrication” table in the ’Technical

data” section.

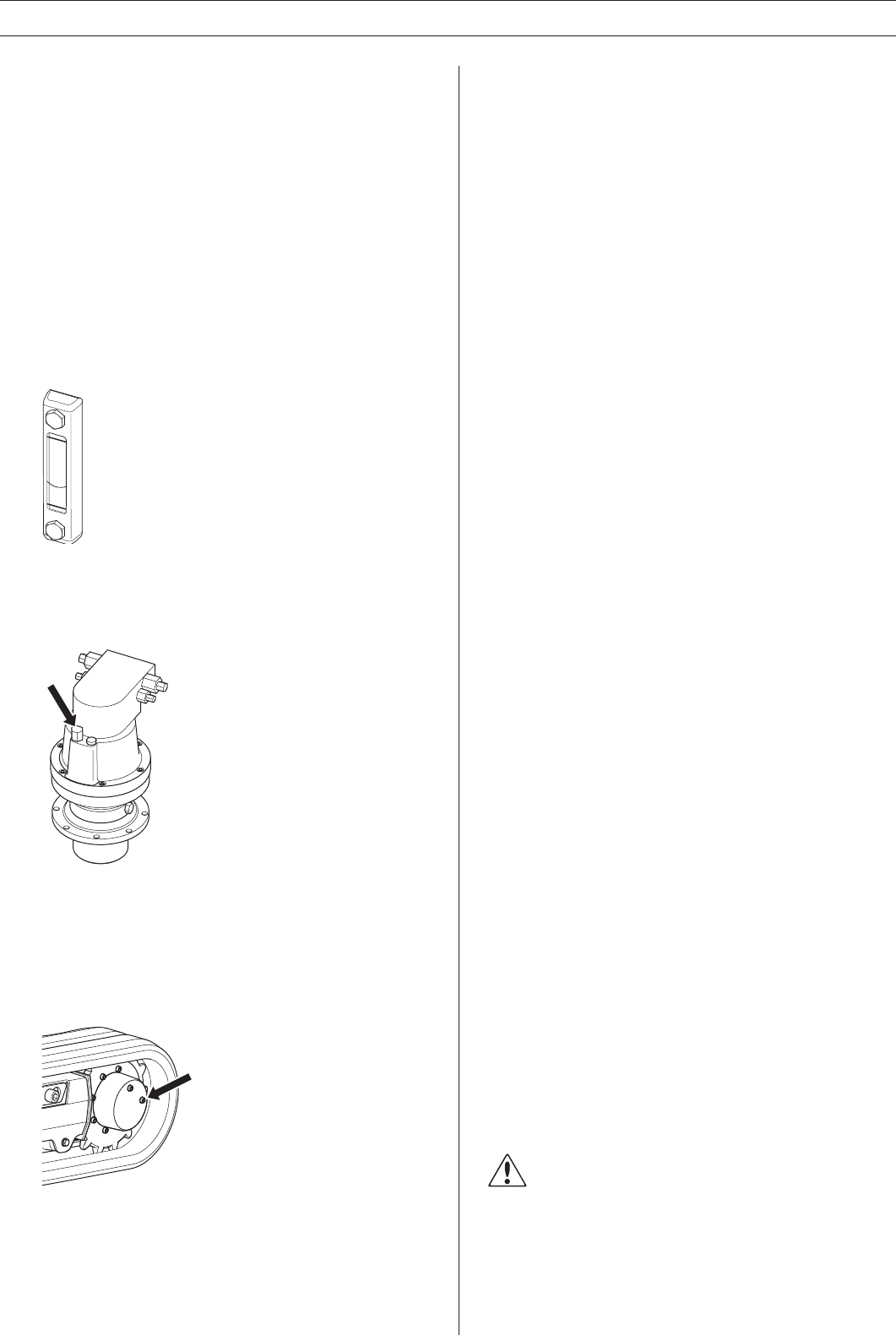

Hydraulic oil

• Manoeuvre the machine so the arm system’s cyl-

inders are retracted and the outriggers are com-

pletely folded.

• Refi lling is needed if the level is more than one cm

below the max mark.

Slew reduction gear unit

• Locate and loosen the dipstick. Wipe it clean, lower

it and read off the level.

Drive motor, drive gear

• Manoeuvre the machine until one of the plugs is

level with the middle of the hub and the other one

is at the top position.

• Unscrew the level plug. The oil level should reach

up to the hole.

Hammer lubrication

• Check that there is grease in the receptacle.

MAINTENANCE AND SERVICE

Wear and damage

General

NB! Deal with worn components as quickly as pos-

sible. There is an increased risk of mechanical break-

down if the machine is used despite damaged or worn

components.

Wear of shafts and slide bearings

Bearings and any shafts necessary must be replaced

in the event of play in joints and cylinder mountings.

Replace or repair damaged components.

• If there is play in joints the bearings must always

be replaced.

• Shafts must be replaced if they have wear damage.

If there is wear damage on an expanding sleeve it

indicates that it has not been suffi ciently tightened.

• Swing joints must be kept lubricated in order to

be able to press out dirt that enters and to reduce

wear on shafts and bearings.

Wear to rubber components

Check that caterpillar tracks and outrigger feet are

intact. If they are so worn that the metal is visible they

should be replaced.

Wear to hydraulic hoses

Do not use hoses that are distorted, worn or dam-

aged. Make sure that the cords are not visible. Always

have a spare hose on hand. Damaged hoses must be

replaced immediately.

• Check that none of the hoses are rubbing against

sharp edges. Be alert to the risk of abrasive jets.

• Adjust the length of hydraulic hoses so that they

are never entirely stretched.

• Ensure that the hose is not twisted during mount-

ing.

• Avoid severe bends in the hose.

Hydraulic couplings

• Check that the couplings are not damaged. Dam-

aged couplings can damage hoses with the result

that they come off. Change damaged couplings

immediately.

• The hydraulic couplings should be lubricated be-

fore tightening to reduce friction.

Wear to electric cables

WARNING!

The power cable must be disconnected when

electric cables are checked. Check that the

cables’ insulating casings are not damaged.

Change damaged cables immediately.

42 - English