Leakage

General

NB! Leakage can cause serious mechanical break-

downs and an increased risk of slipping. Wash the

machine regularly to increase the chance of detecting

leakage at an early stage. Deal with leaks as quickly as

possible and refi ll if necessary.

Hydraulic fl uid

Leakage of hydraulic fl uid leads to an increased risk of

dirt getting into the hydraulic system which can lead

to breakdowns and mechanical damage. If you detect

hydraulic fl uid underneath the machine or on the base

plate it is probably due to leakage.

• Check for leakage at the hose connectors, cou-

plings and cylinders. Leakage can also occur at

other hydraulic components and can manifest itself

with a strip of dirt.

Cracks

General

A clean machine makes it easier to detect cracks.

The greatest risk of crack formation is:

• At weld seams

• At holes or sharp corners

Lower part

• Check in particular whether cracks have appeared

around outrigger mountings both on the lower part

and on the outriggers, gear ring mounting and weld

seams between the machine body and the track

sides.

Arm system

• Check in particular whether cracks have appeared

on the arm system’s joints, cylinder mountings and

weld seams.

MAINTENANCE AND SERVICE

Welding work on the machine

Only qualifi ed welders should carry out welding opera-

tions on the machine.

WARNING!

Risk of fi re. The machine contains fl ammable

liquids and components. Do not undertake any

welding in direct connection with fl ammable

liquids, e.g. in the vicinity of tanks, fuel lines or

hydraulic pipes. Ensure that there is a fi re-extin-

guisher on site at the workplace.

Risk of inhaling harmful substances. Toxic gases

can be formed. When welding indoors, use

equipment to extract welding fumes. Never weld

in the vicinity of rubber or plastic material. Use a

breathing mask.

Components that should not be welded

The following components should not be repaired but

replaced:

• Tool attachment

• Link

• Cotters

• Mounting plate

• Cylinders

• Hydraulic tank

• Cast parts

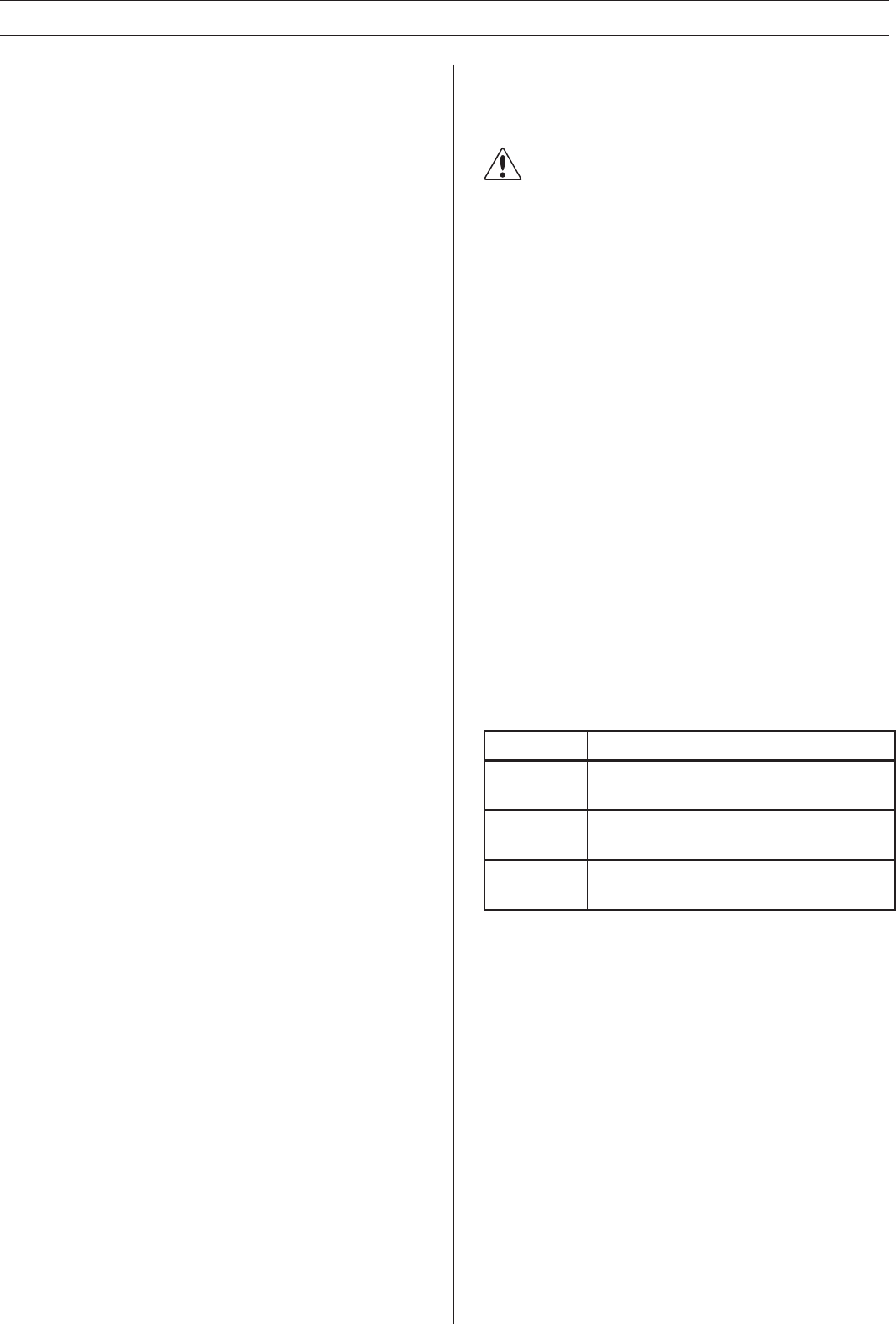

Recommended welding wire

Type Recommended material

Flex cored

wire

Esab OK 14.03 Tubrod

Class: AWS A5.28 E110C-G

Solid Elgamatic 100

Class: AWS A5.18 ER70S-6

Rod Esab OK 75.75

Class: AWS A5.5 E11018-G

English - 43