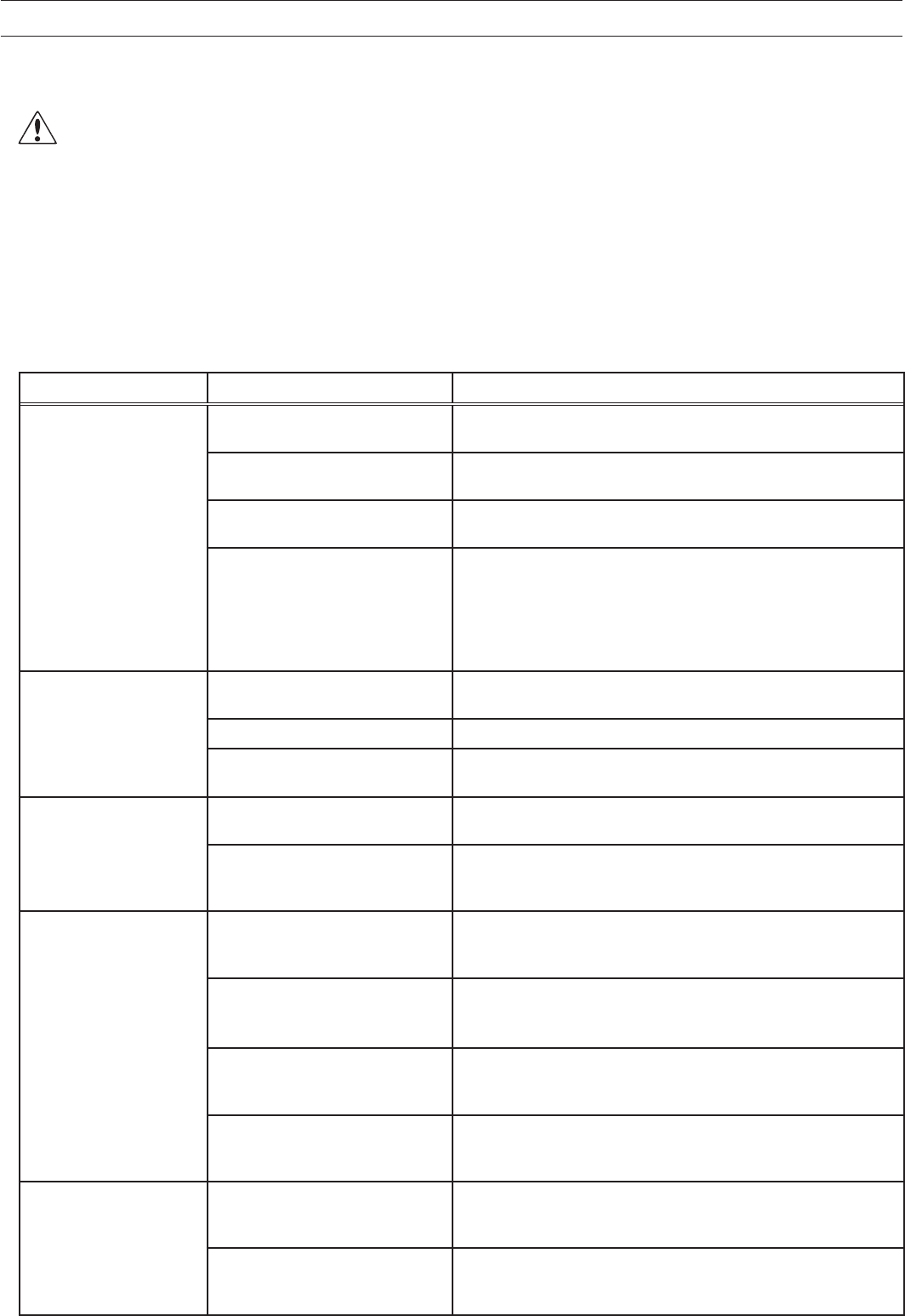

TROUBLE SHOOTING

Trouble shooting guide

WARNING!

Most accidents involving machines occur during trouble shooting, service and maintenance as staff have to

locate themselves within the machine’s risk area. Prevent accidents by being alert and by planning and prepar-

ing the work. You can also refer to ’Preparations for maintenance and service” in the ’Maintenance and serv-

ice” section.

If service operations or trouble shooting does not require the machine to be switched on, the power cable

must be removed and positioned so that it cannot be connected by mistake.

Following the trouble shooting guide will provide you with tips to facilitate the trouble shooting process. You can also

perform simpler trouble shooting operations. The operator may only carry out the maintenance and service opera-

tions that are described in this Operator’s Manual. More extensive interventions must be carried out by an authorized

service workshop.

Always start by checking any error messages on the remote control. Follow the instructions for the respective mes-

sage in accordance with the error messages section.

Fault Cause Possible action

The electric motor

does not start

Emergency stop/machine stop

is pressed.

Check that the emergency stop or machine stop button

are not pressed by turning them clockwise.

Too low mains voltage to the

machine.

Check power supply and ensure correct voltage.

A fuse has blown. Check that the mains voltage is compatible with the ma-

chine and that the correct fuses are used.

No radio communication

between remote control and

machine.

Green symbol in the display indicates contact. If the symbol

does not light up, check that the battery for the remote con-

trol is charged and correctly inserted. Ensure that the cor-

rect remote control is being used. Check that the commu-

nication cable and aerial cable on the machine are properly

secured. Test run the machine using cable control.

Fuses for the mains

connection blow when

starting.

The machine’s fuses have too

low a rating.

Check that the mains voltage is compatible with the ma-

chine and that the correct fuses are used.

Electric motor blown. Contact your service agent.

The hydraulic pump has cut

out.

Contact your service agent.

The machine works

but the motor speed

decreases substantial-

ly during operation.

Too low mains voltage to the

machine.

Check power supply and ensure correct voltage.

Incorrectly dimensioned

power cable.

Ensure that the power cable is correctly dimensioned.

Refer to “Guide values for mains connection” in the

“Technical data” section.

The motor runs but

the hydraulic functions

have no power or do

not work at all.

Not enough hydraulic fl uid

in the tank. (Knocking noise

coming from the tank.)

Stop the motor at once. Investigate and rectify any leaks

there might be. Replenish hydraulic fl uid.

Pump around valve open. Check the diode on the valve cap at the bottom of valve

block 1. If the pump around valve is open the diode does

not light up. Check the cable to the control module.

Fault in the pump regulator. Extend an unloaded cylinder to its end position and

check the pump pressure in the display (under “Service”).

If you get maximum pressure the pump regulator is OK.

Pressure at rest set too low. Activate the remote control without running any functions

and check the setting for pressure at rest in the display.

The pressure should not exceed 16 Bar.

Arm movements

and tool function run

slowly.

The potentiometer that con-

trols mechanical movements/

tools is screwed down.

Unscrew the knob(s).

Pressure at rest set too low. Activate the remote control without running any functions

and check the setting for pressure at rest in the display.

The pressure should not exceed 16 Bar.

48 - English