Transport and storage

Lifting the machine

• When lifting the machine there is a risk of injuring

persons or damaging the machine or the surround-

ings. Defi ne the risk area and check that nobody is

present within the area when lifting.

• Use an approved lifting device to secure and lift

heavy machine parts. Also ensure that there is

equipment to secure machine parts mechanically.

• Retract the arm system. The centre of gravity must

be as close to the machine’s centre as possible.

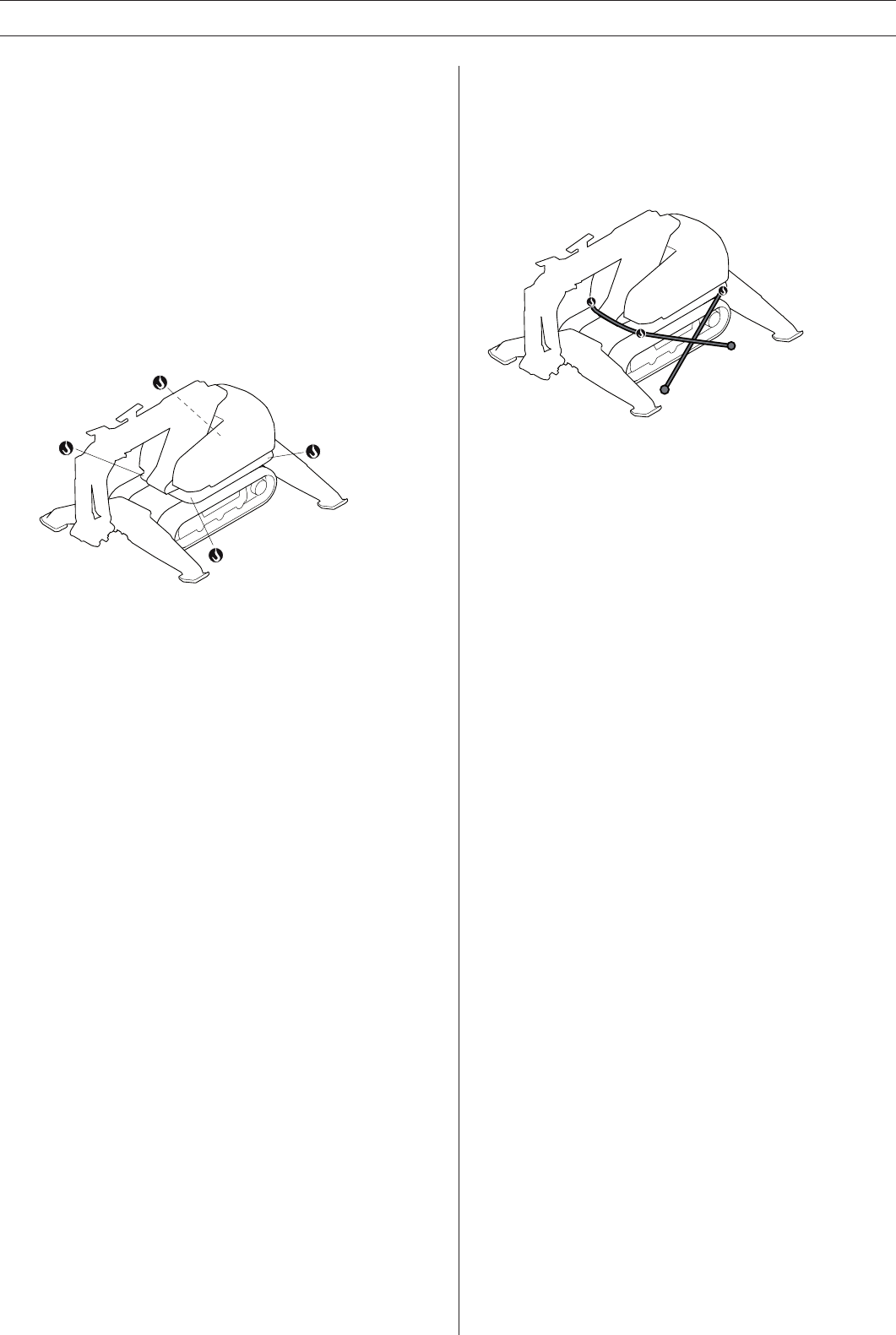

• The lifting equipment must be attached at all the

machine’s lifting eye bolts.

• Lift slowly and carefully. Make sure that the lift is in

equilibrium and if the machine starts to lean, rectify

it by using an alternative lifting device or change

the position of the arm system.

• Ensure that the machine’s parts are not crushed or

damaged when lifting and that the machine does

not hit surrounding objects.

Loading and unloading using a ramp

• Ensure that the ramp is intact and the right size for

the machine.

• Check that the ramp is free of oil, mud or anything

else that might make it slippery.

• Ensure that the ramp is properly secured to both the

vehicle and the ground. The vehicle being used for

transportation must also be secured so that it cannot

move.

Transport

• The machine may only be transported on a fl atbed

truck or a trailer that is approved for the machine’s

weight, refer to the machine’s rating plate. The

remote control must be properly protected in the

vehicle during transportation.

• Check applicable road traffi c regulations before

transporting on public roads.

The machine’s position on the loading platform

• Position the machine against the front edge of the

platform in order to reduce the risk of it sliding

forward if the vehicle brakes.

• Manoeuvre the arm system so that it is resting

against the platform, positioned as low as possible.

Extend the outriggers without lifting the machine.

Securing the machine

• Secure the machine with approved tightening

straps. Use the machine’s lifting eye bolts. Ensure

that no part of the machine are squashed or dam-

aged by the tightening straps. It is a good idea to

cover the machine.

• Tools and other equipment must be secured with

separate tightening straps.

• Regularly check that the load is secure during

transportation.

Storage

• Remove the tool from the machine.

• Retract the arm system to attain a centre of gravity

that is as low as possible and to save space.

• Store the equipment in a lockable area so that it is

out of reach of children and unauthorized persons.

• Store the machine and its equipment in a dry and

frost proof place.

Towing

The machine is not designed to be towed. When the

machine is depressurized, the drive motor’s parking

brakes are activated and the caterpillar tracks cannot

rotate. Only tow the machine if its position constitutes

a risk and there is no other solution. Tow it for the

shortest possible distance.

• If possible, retract the outriggers before towing the

machine in order to reduce the risk of them getting

stuck and being damaged.

• To minimize the load on the towing device and

mechanical components, reduce the friction by

preparing the route that the machine is going to be

towed.

• If possible tow in the direction of the tracks.

• Use the lifting eye bolts to connect to the tow-

ing device. Use a towing device intended for the

particular load.

• Parts can loosen during towing. Keep your dis-

tance!

SAFETY INSTRUCTIONS

12 - English