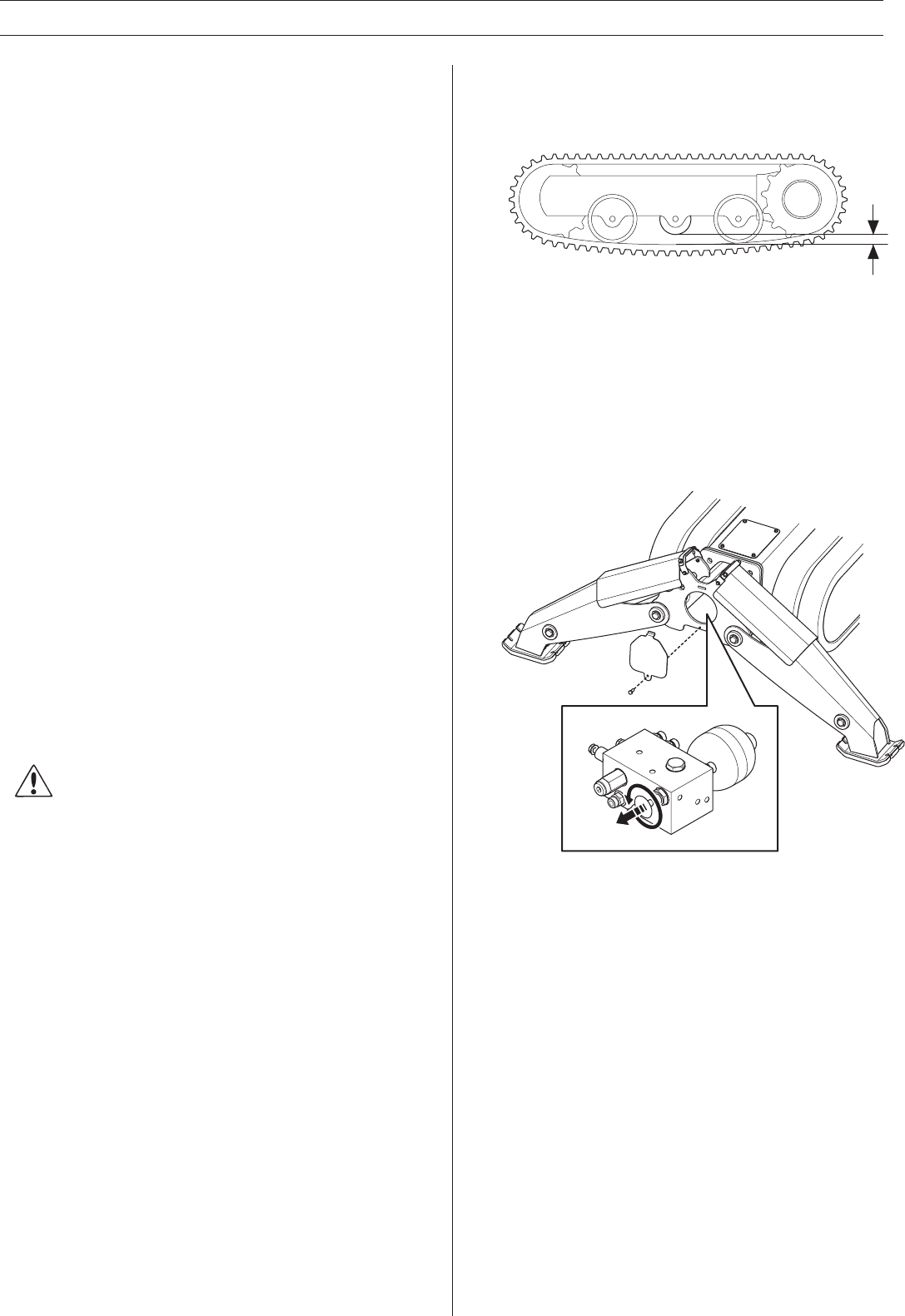

Checking track tension

• The track must not slacken by more than 10-15

mm. Operate the outriggers up and then down.

Wait 15 minutes and then check.

• If the tracks become slack it can be due to one of

the track tensioning function’s non-return valves

being blocked or broken.

Cleaning non-return valves

The non-return valves can be cleaned by discharging

the pressure in the accumulator and thus loosening

the tension of the tracks.

• Pull out the valve and rotate it a quarter turn to lock

it in open position.

• Operate the outriggers up and down. Hydraulic

fl uid is then pumped around and cleans the non-

return valve.

• Rotate and release the valve back into position.

Operate the outriggers up and down to tension the

track.

Hammer lubrication

Check that grease is reaching the hammer by dis-

mantling the grease hose at the hammer. Start the

machine and activate the hammer function. Exercise

great caution during the inspection to ensure that

nobody is injured.

Tools

Check that the tool can be used in such a way that

neither the operator nor people in the vicinity are

exposed to unnecessary risks. Refer to the supplier’s

Operator’s Manual for other checks.

Functional inspection

General

Functional inspections must ensure that the machine’s

functions are intact.

Brake functions

• Check the drive brake’s function by operating the

machine on a slope. Release the joysticks. The ma-

chine should then be braked and remain stationary.

• Check the slew brake’s function by rotating the arm

on a slope. Release the joysticks. The arm should

then be braked and stop gently.

Cooler

Overheating has a negative effect on the service life

of the machine’s components. Clean the cooler when

necessary. Refer to “Cleaning the machine” in the

“Maintenance and service” section.

Cylinders

Checking cylinder tubes and piston rods must be

done with the cylinders extended to the end position.

Replace damaged components immediately.

• Check that the cylinder tubes are not dented or

cracked.

• Check that the piston rods are undamaged and

straight. A damaged piston rod causes contamina-

tion in the hydraulic system, resulting in mechani-

cal damage.

Tool attachment

Warning!

The tool attachment’s cotter and pin are impor-

tant safety components. A worn or damaged

cotter must be replaced with an original spare

part, manufacturing your own cotters is not

permitted.

• Check that the tool attachment is complete and

that all parts are intact and correctly mounted.

Automatic track tensioning

The caterpillar tracks are tensioned automatically

when the outriggers are up.

Should demolition material or suchlike enter into the

side of the tracks during operation, their spring func-

tion should prevent breakdowns and stoppages. The

spring function consists of a hydraulic accumulator.

MAINTENANCE AND SERVICE

44 - English