Change

IMPORTANT!

Chemicals such as degreasing agent, grease,

fuel, glycol and hydraulic fl uid can give rise to

allergies in conjunction with repeated skin con-

tact. Avoid contact with the skin, use protective

equipment.

General

Changing liquids and fi lters must be done in such a

way that the machine’s hydraulic system and the sur-

rounding environment are not damaged. Dispose of

residual products according to local laws.

Position the machine on a fl at surface. Discharge the

machine and allow it to cool. Clean the component

before opening it for refi lling in order to prevent dirt

getting in. If the level is low, fi ll in accordance with the

following instructions.

Hydraulic fl uid

IMPORTANT!

Allow the machine to cool. Hot oil can cause

severe burn injuries.

General

The quality of hydraulic fl uid that the machine was

supplied with is indicated on the sticker on the ma-

chine’s hydraulic tank. Refer also to ’Technical data”

for choice of suitable hydraulic oils.

OBS! The machine can be damaged if different types

of hydraulic fl uid are mixed. Check which quality of

hydraulic fl uid the machine’s hydraulic system contains

before refi lling or changing. Do not use hydraulic fl uid

that is not recommended.

Draining hydraulic fl uid

• Manoeuvre the machine so the arm system’s cyl-

inders are retracted and the outriggers are com-

pletely folded.

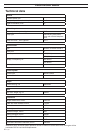

• Undo the air fi lter so that the overpressure in the

tank is discharged.

MAINTENANCE AND SERVICE

• Place a collecting vessel under the tank’s drain

plug and open the plug.

• Screw on the drain plug when all the liquid has

drained out.

• Changing oil fi lters. Refer to ’Oil fi lter” in the ’Main-

tenance and service” section.

• Tighten the air fi lter.

NB! Do not start the motor when the hydraulic tank is

empty, the hydraulic pump will be damaged.

Replenishing hydraulic fl uid

The machine is equipped with a refi ll pump.

• Manoeuvre the machine so the arm system’s cyl-

inders are retracted and the outriggers are com-

pletely folded.

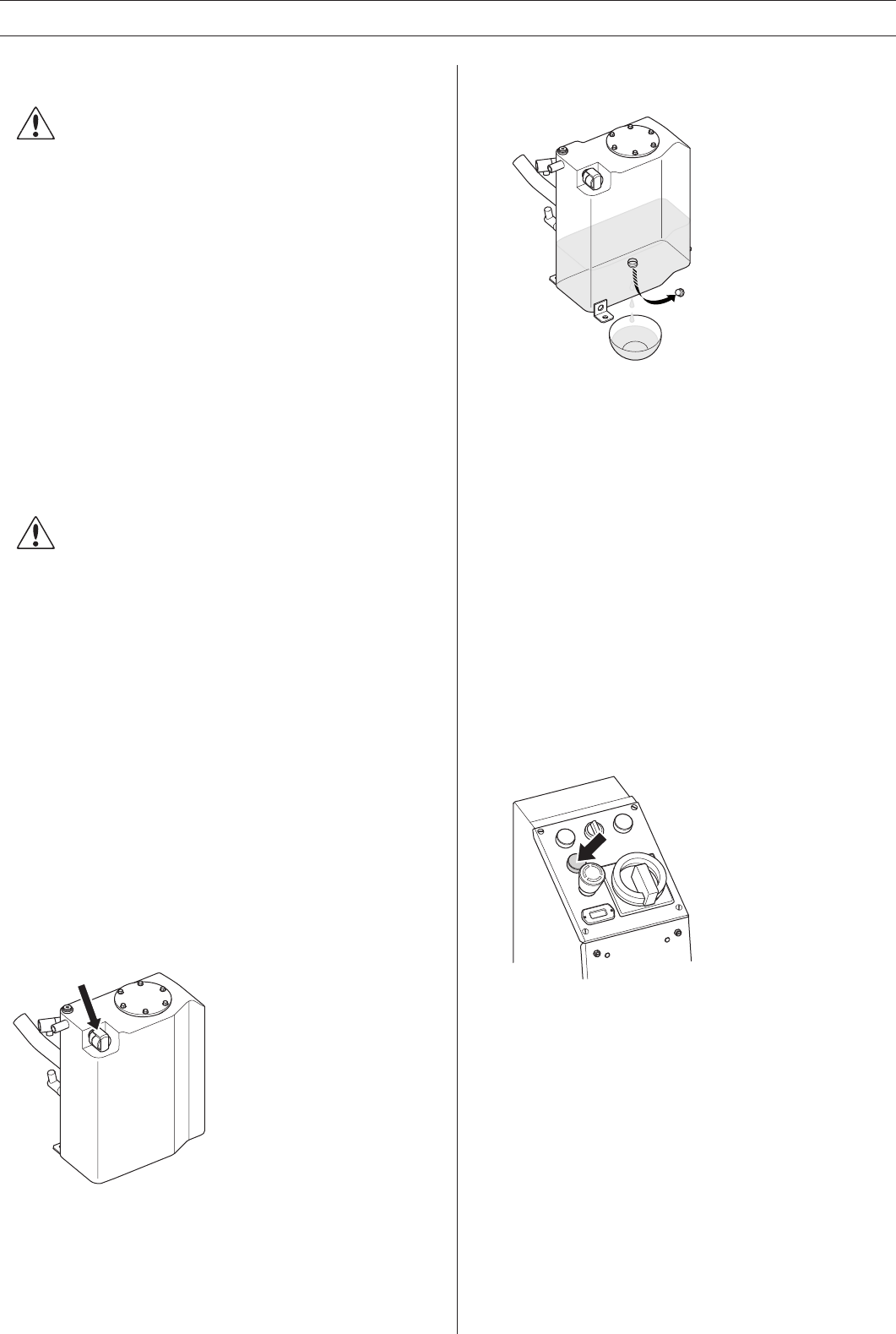

• Clean the refi ll pump’s suction hose. Remove the

plug and put the hose into the fl uid container.

• Press in the refi lling button to start the pump.

• Use the sight gauge to check the oil level when

refi lling.

• Start the machine and operate the cylinders be-

tween outer and inner end position a number of

times to remove air that might have entered the

hydraulic system while refi lling.

English - 45