TP-6880 10/1460 Section 5 Scheduled Maintenance

The fuel system. Explosive fuel vapors can cause severe

injury or death. Vaporized fuels are highly explosive. Use

extreme care when handlingand storing fuels. Store fuels in a

well-ventilated area away from spark-producing equipment

and out of the reach of children. Never add fuel to the tank

while the engine is running because spilled fuel may ignite on

contact with hot parts or from sparks. Do not smoke or permit

flames or sparks to occur near sources of spilled fuel or fuel

vapors. Keep the fuel lines and connections tight and in good

condition. Do notreplaceflexiblefuel lineswithrigid lines. Use

flexible sections to avoid fuel line breakage caused by

vibration. Do not operate the generator set in the presence of

fuel leaks, fuel accumulation, or sparks. Repair fuel systems

before resuming generator set operation.

Gas fuel leaks. Explosive fuel vapors can cause severe

injuryor death. Fuel leakagecan cause a nexplosion. Check

the LP vapor gas or natural gas fuel system for leakage by

using a soap and water solution with the fuel system test

pressurized to 6--8 ounces per square inch (10--14 inches

water column). Do not use a soap solution containing either

ammonia or chlorine because both prevent bubble formation.

A successful test depends on the ability of the solution to

bubble.

LP liquidwithdrawal fuelleaks. Explosivefuel vaporscan

cause severe injury or death. Fuel leakage can cause an

explosion. Check the LP liquid withdrawal gas fuel system for

leakage by using a soap and water solution with the fuel

system test pressurized to at least 90 psi (621 kPa). Do not

use a soap solution containing either ammonia or chlorine

because both prevent bubble formation. A successful test

depends on the ability of the solution to bubble.

See the Safety Precautions and Instructions at the

beginning of this manual before attempting to service,

repair,or operatethe generatorset. Have anauthorized

distributor/dealer perform generator set service.

RoutineMaintenance. Refer tothe followinggenerator

set service schedule, the engine service schedule, and

the runtime hours d isplayed on the generator set

controller to determine when to schedule routine

maintenance. Service the generator set more

frequently if it is subject to extreme weather, long

operating hours, or dusty or dirty conditions.

Maintenance Reminders. The RDC2 and DC2

controllersdisplaya remindermessageevery100hours

of engine run time. Change the oil and perform other

maintenance tasks listedon theservice schedule. Then

reset the reminder. See Section 5.2.5 for instructions to

reset the maintenance reminder.

Service Schedule. Perform maintenance on each item

in the service schedule at the designated interval for the

life of the generator set.

Tools. Tools and instruments used to perform some

maintenance items are not generally available to the

generator set owner. Therefore, have service

performed by an authorized distributor/dealer.

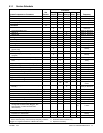

5.1 Scheduled Maintenance

Refer tothe followingservice schedulesand the runtime

hours displayed on the controller display to schedule

routine maintenance. Intervals are shown in hours of

operation and/or time intervals (i.e. weekly, monthly,

quarterly, etc.) Have an authorized distributor/dealer

service the generator set at the designated intervals in

the service schedule for the life of the generator set.

Serviceunits subjecttoextremeweather,longoperating

hours, or dusty or dirty conditions more frequently.

Contact an authorized distributor/dealer for parts.