A-5

INSTALLATION

LN-742 & LN-742H

A-5

WORK CABLE

Connect a work lead of sufficient size and length

(Table A.1) between the proper output stud on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal electrical contact.

TABLE A.1 – WORK LEAD SPECIFICATIONS

Copper Work Cable Size, AWG

Current 60% Up To 50 Ft 50 Ft-100 Ft

Duty Cycle (15.2 m

2

) (15.2-30.4 m

2

)

300 Amps 0 (53 mm

2

) 00 (67 mm

2

)

400 Amps 00 (67 mm

2

) 000 (85 mm

2

)

500 Amps 00 (67 mm

2

) 000 (85 mm

2

)

600 Amps 000 (85 mm

2

) 0000 (107 mm

2

)

GUN AND CABLE ASSEMBLIES

The LN-742 can be used with several guns. In most

cases, Lincoln guns and cables are shipped

assembled, ready to weld. Use the gun and cable

assembly for the electrode type (solid, Outershield , or

Innershield) and electrode size to be used. Refer to

Section C, Accessories, for different gun types.

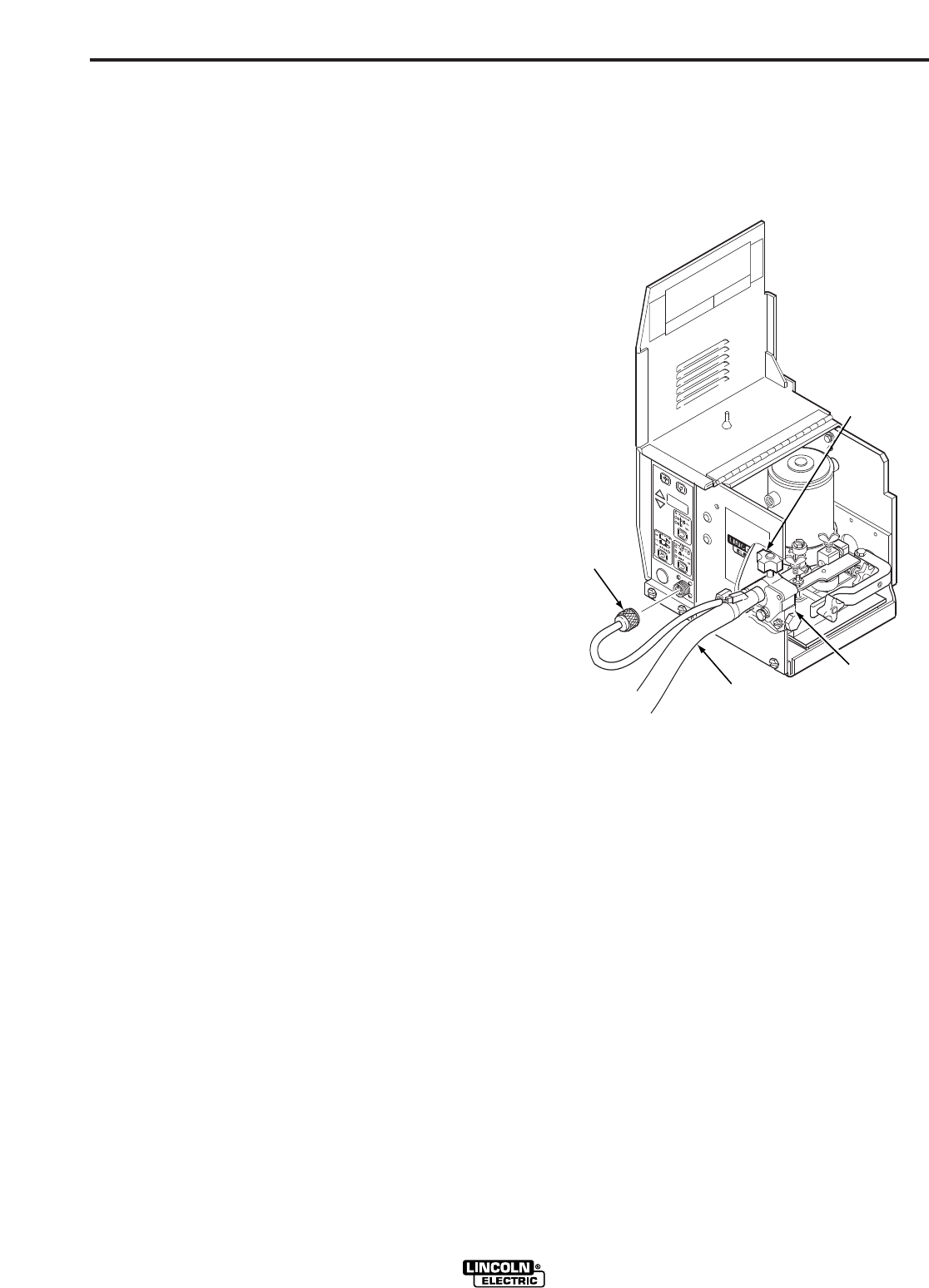

GUN CABLE CONNECTIONS

Lay the cable out straight. Insert the connector on the

welding conductor cable through the large hole in the

front panel of the LN-742 and into the brass conductor

block on the front of the gearbox. Refer to Figure A.4.

Make sure it is all the way in and tighten the locking

knob. Keep this connection clean and bright.

Connect the control cable amphenol plug into the

mating 5-cavity receptacle on the front of the control

section below the keypad.

FIGURE A.4 – GUN CABLE CONNECTIONS.

AMPHENOL

PLUG

GUN CABLE

ASSEMBLY

CONDUCTOR

BLOCK

LOCKING

KNOB