E-3

TROUBLESHOOTING

E-3

LN-742 & LN-742H

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

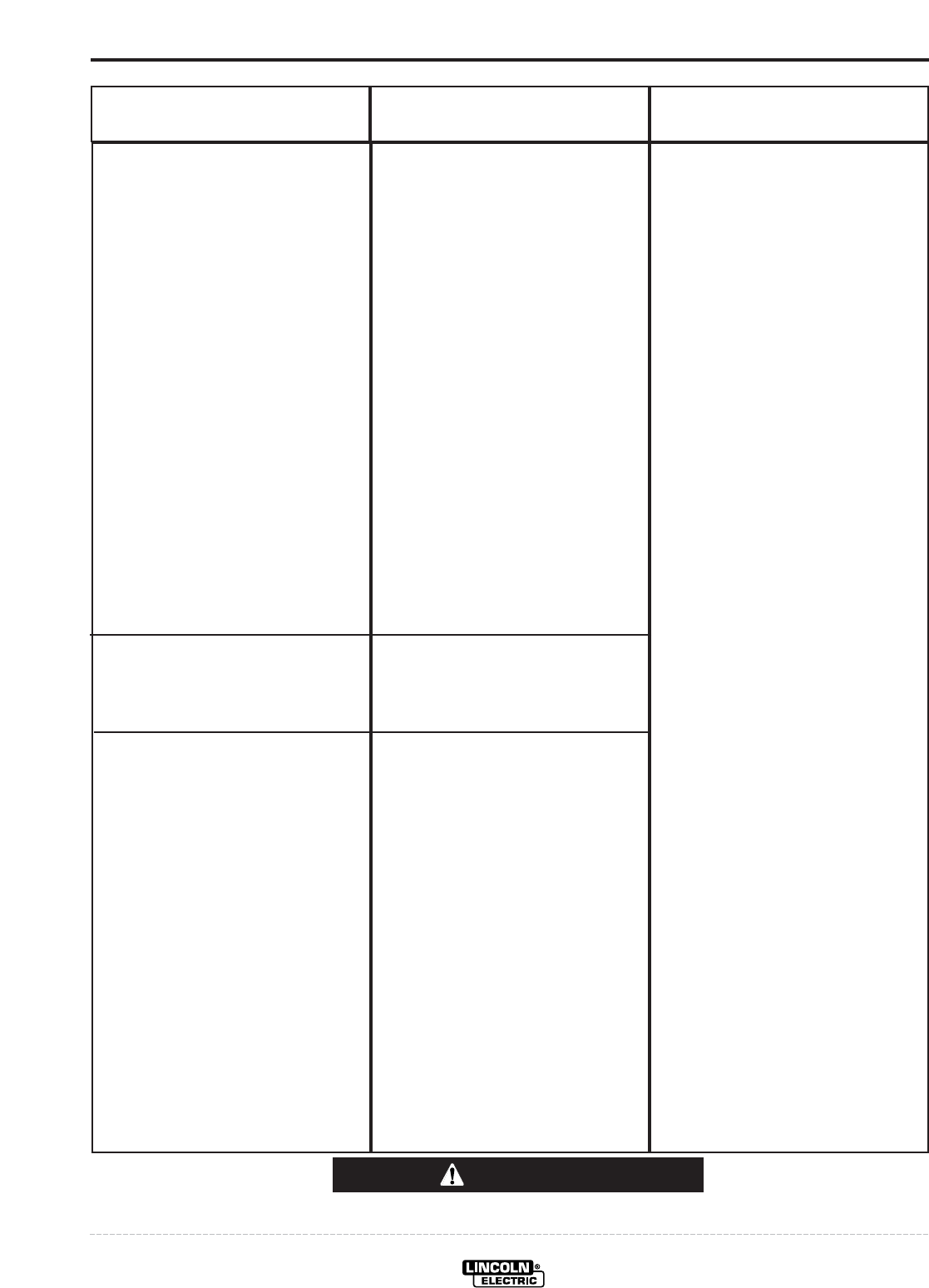

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

When the gun trigger is activated

the wire feed motor runs and the

solenoid functions but no arc volt-

age is present.

The wire feeds when the gun trig-

ger is activated but there is no con-

trol of the wire feed speed.

The wire feed speed does not

change when welding current

begins to flow.

1. Make sure the welding power

source is functioning properly.

Disconnect the control cable

from the Lincoln power source.

Place a jumper across sockets

C and D of the 14 pin amphenol

plug at the power source. Open

circuit voltage should be pre-

sent at the welder output termi-

nals. If no voltage is present at

the output terminals the power

source is faulty.

2. The control cable may be faulty.

Check leads #2 and #4 (pins C

and D) for continuity (zero

ohms).

3. The welding cables may me

faulty. Check for loose or faulty

connections.

4. The gun may be faulty. Check

or replace.

1. Check for loose or faulty con-

nections between the tach and

the control board plug J3.

1. The inch and weld speeds may

be set to the same value.

2. If the display shows the ----

symbol the inch speed has

been disabled. To enable the

inch speed press the increase

arrow key.

3. Check plug J2 on the control

board for loose or faulty con-

nections.

If all recommended possible areas of

misadjustment have been checked

and the problem persists, Contact

your local Lincoln Authorized

Field Service Facility.