OM-842 Page 10

2-3. User Relay Contacts

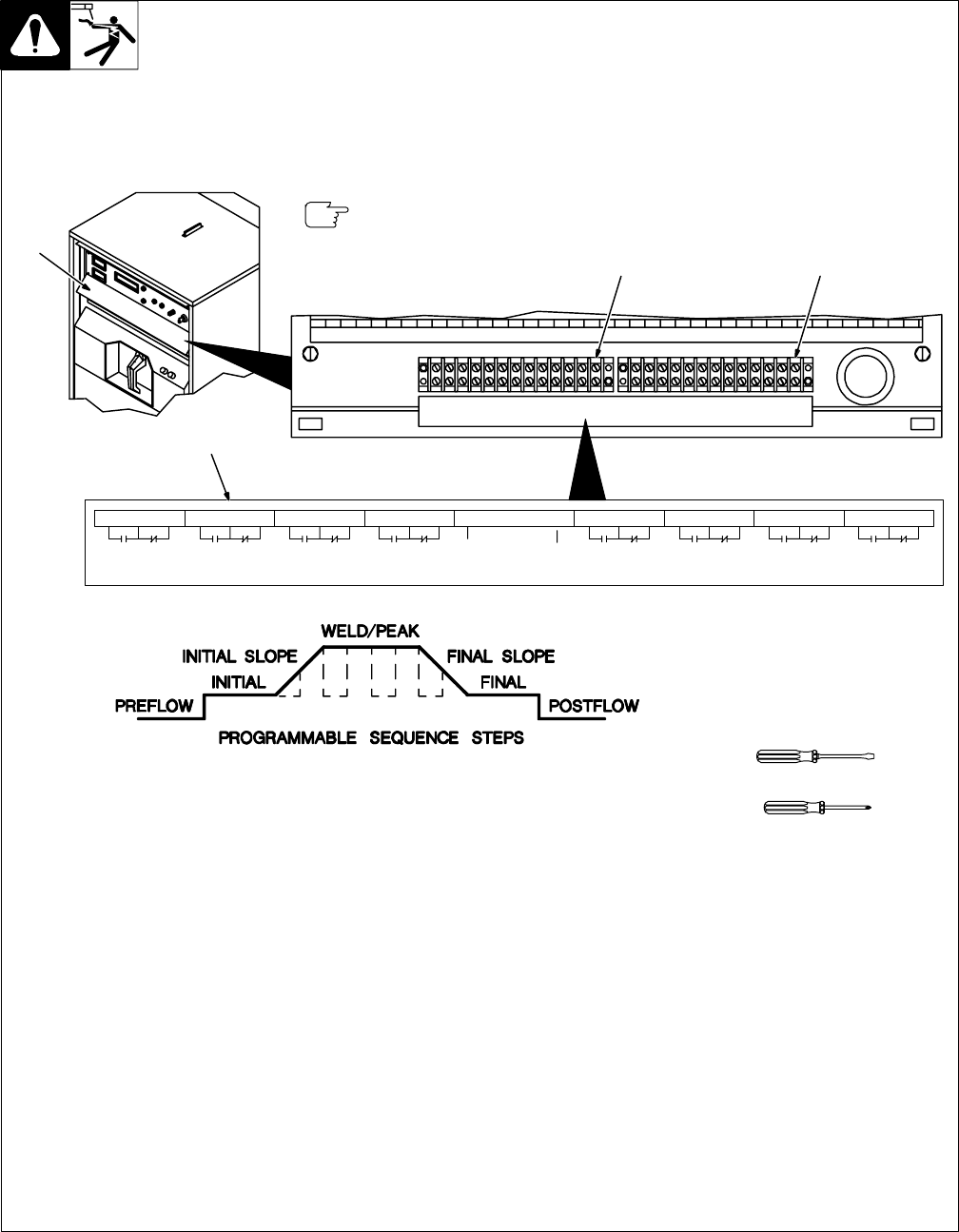

Ref. ST-162 477-A / ST-162 841 / Ref. SC-159 862

1 Access Door

Access door is hinged at top, and held

closed with industrial interlock strips. To

open, grasp bottom and pull out firmly.

2 Terminal Strip 3T

3 Terminal Strip 4T

4 Connection Label

Use 3T and 4T to connect external equip-

ment to internal relay contacts. Pairs of nor-

mally closed and normally open contacts are

provided for each weld sequence step, the

pulse signal, and for a wire feeder.

Each set of weld sequence contacts

changes state at the beginning of the match-

ing part of the weld sequence, and resets at

the end of postflow. For example, the initial

slope contacts change state when initial

slope begins, and reset at the end of post-

flow. The user relay contacts change state

regardless of the time value programmed for

the matching portion of the weld sequence.

If 0.0 seconds was entered as a time value

for final slope, the user relay contacts match-

ing final slope and final current would change

states at the same time.

The pulse signal contacts change state as

pulsed output goes between peak and back-

ground amperage.

The wire feed contacts operation is program-

mable, and is explained where needed in

Section 5.

To make connections, route leads through

openings in either side of access door, and

make connections to terminals according to

the connection label.

Close access door.

1

ABCDEFGHJKLMN PRSTUVWXYZAABBCC

INITIAL TIME INITIAL SLOPE WELD PEAK FINAL SLOPE FINAL TIME POST FLOW PULSE SIGNAL WIRE FEED

WELD

TIME

CONTACTS

S-157 815

2 3

4

Tools Needed:

Or

The internal control relay

contacts accessible through

terminal strips 3T and 4T are

rated at 20 amperes, 250 volts.