OM-842 Page 16

SECTION 4 – INTRODUCTION TO PROGRAMMING

4-1. General

Programs are created when parameters are defined in a series of displays. Up to four programs can be entered into each of the four

modes of operation, for a total of sixteen programs. In addition, programs in certain modes can be linked or combined to run in a

user-defined sequence.

This welding power source provides high frequency or scratch starting, preflow timing, start current level control and timing, initial

current level control and timing, initial slope timing, final slope timing, final current level control and timing, postflow timing, and am-

perage control of weld/peak current for either a pulsing or nonpulsing weld current. Pulsing controls include on/off selection, pulse

peak level control and timing, background current level control and timing, and pulse frequency and average current calculations.

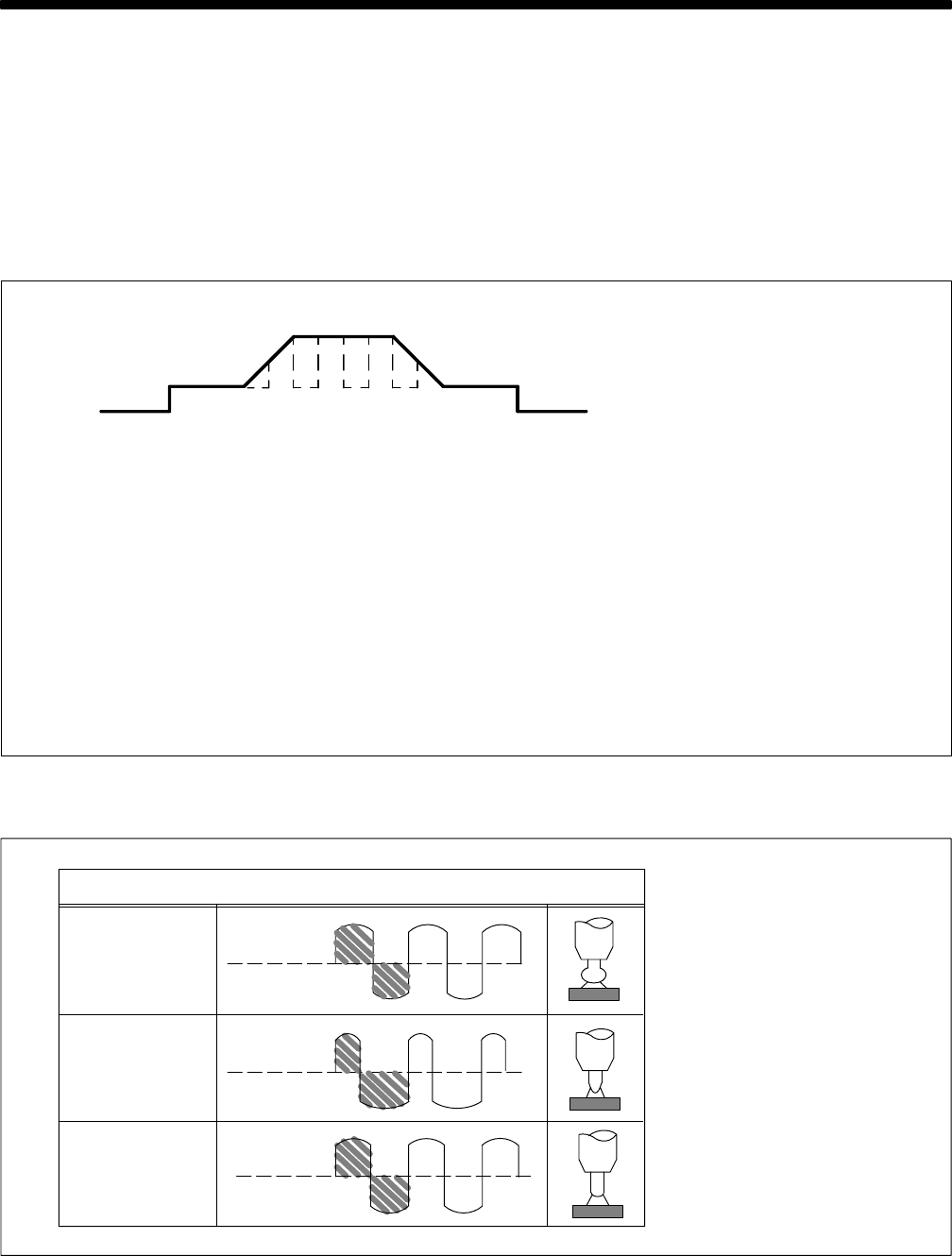

4-2. Weld Sequence

Ref. SB-139 983

In most cases, the weld sequence

shown here is used in programming

the control. Which steps are pro-

grammable and what initiates each

step varies from mode to mode.

Initial

Current

Weld/Peak

Current

Initial

Slope

Final

Slope

Final

Current

Preflow

Postflow

Preflow: The period during which shielding gas flows before an arc is

established.

Start Level (Not Shown): A current level that can be programmed to ease

arc starting.

Initial Current: The beginning maintained current level.

Initial Slope: The ramping of the initial current up to the programmed weld/

peak current level.

Weld/Peak Current: The programmed weld current level (divided into peak

and background current levels when pulsing is enabled).

Final Slope: The ramping down of weld/peak current to the programmed final

current level.

Final Current: The end current level just before the arc is extinguished.

Postflow: The period during which shielding gas flows after the arc has been

extinguished.

4-3. Balance Control

When ac output is selected on the

Process Selector switch, a balance

control value must be programmed.

The balance control value can be

used to change the weld arc charac-

teristics for either more penetration

or more cleaning. The electrode

negative (EN) value is user-

programmed, and the electrode pos-

itive (EP) value changes accordingly

so the sum always equals 100%.

50% Electrode

50% Electrode

Negative

Positive

Balance Control Waveform Examples

More Cleaning

More Penetration

Balanced

55% Electrode

45% Electrode

Positive

Negative

32% Electrode

68% Electrode

Positive

Negative