OM-842 Page 18

Ref. SB-139 983

In this mode, time values are not de-

fined for initial current, weld/peak

current, and final current. The micro-

processor control operates in a mo-

mentary-contact, single button for-

mat. The operator presses the Start/

Increase push button to start the pro-

gram, presses it again to signal the

end of initial current, presses it again

to signal the end of weld/peak cur-

rent, and presses it for a last time to

signal the end of final current.

The weld amperage cannot be in-

creased or decreased once the se-

quence has started.

If Stop Button Detect is enabled in

the weld program, pressing the Stop

push button stops program execu-

tion and starts postflow. If Stop But-

ton Detect is disabled, pressing the

Stop push button has no affect.

Postflow starts if the arc is manually

broken.

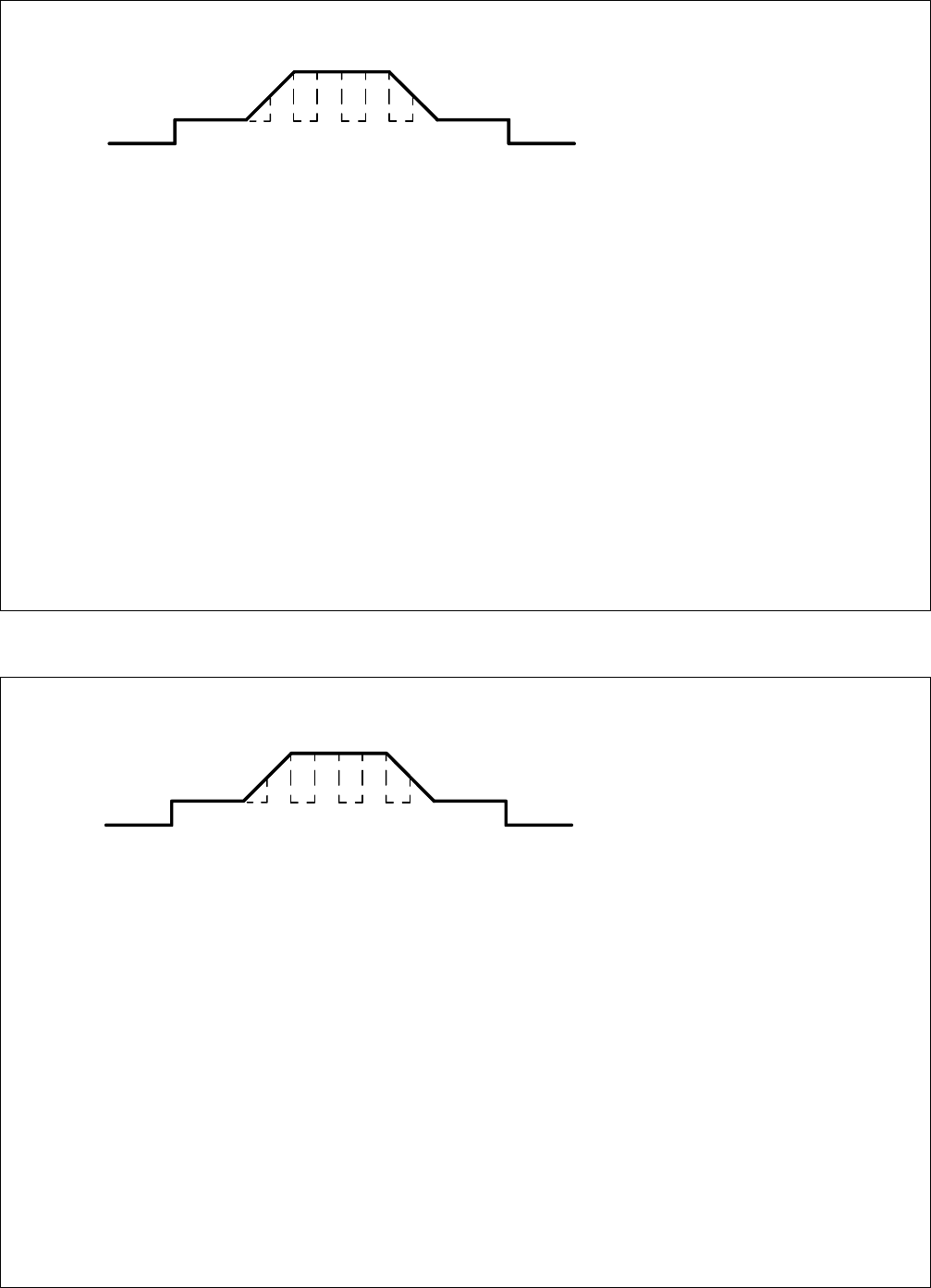

A: Momentary closure of Start/Increase push button starts sequence.

B: Momentary closure of Start/Increase push button ends initial current.

C: Momentary closure of Start/Increase push button ends weld/peak cur-

rent.

D: Momentary closure of Start/Increase push button ends final current.

Preflow: Time programmed/Volume set by gas meter.

Start Level (Not Shown): Time & level programmed.

Initial Current: Time undefined/Level programmed.

Initial Slope: Time programmed/Slope calculated by microprocessor

control.

Weld/Peak Current: Time undefined/Level programmed.

Final Slope: Time programmed/Slope calculated by microprocessor

control.

Final Current: Time undefined/Level programmed.

Postflow: Time programmed/Volume set by gas meter.

Weld/peak current cannot be increased or decreased during welding.

Stop push button functions throughout sequence if Stop Button Detect is en-

abled in the program.

A

Initial

Current

Weld/Peak

Current

Initial

Slope

Final

Slope

Final

Current

Preflow

Postflow

C

B

D

Figure 4-2. Semi-Automatic 2 Mode Sequence

Ref. SB-139 983

In this mode, time values are not de-

fined for initial current, weld/peak

current, and final current. The micro-

processor control operates in a

maintained-contact, single button

format. The operator presses and

holds the Start/Increase push button

to start the sequence. The Start/In-

crease push button is released to

signal the end of initial current. The

sequence will then cycle through to

weld/peak current. The operator

presses and holds the Start/In-

crease push button to signal the end

of weld/peak current. The sequence

will then cycle through to final cur-

rent. The Start/Increase push button

is released to signal the end of final

current.

The weld amperage cannot be in-

creased or decreased once the se-

quence has started.

If Stop Button Detect is enabled in

the weld program, pressing the Stop

push button stops program execu-

tion and starts postflow. If Stop But-

ton Detect is disabled, pressing the

Stop push button has no affect.

Postflow starts if the arc is manually

broken.

A: Maintained closure of Start/Increase push button starts sequence.

B: Release of Start/Increase push button ends initial current.

C: Maintained closure of Start/Increase push button ends weld/peak cur-

rent.

D: Release of Start/Increase push button ends final current.

Preflow: Time programmed/Volume set by gas meter.

Start Level (Not Shown): Time & level programmed.

Initial Current: Time undefined/Level programmed.

Initial Slope: Time programmed/Slope calculated by microprocessor

control.

Weld/Peak Current: Time undefined/Level programmed.

Final Slope: Time programmed/Slope calculated by microprocessor

control.

Final Current: Time undefined/Level programmed.

Postflow: Time programmed/Volume set by gas meter.

Weld/peak current cannot be increased or decreased during welding.

Stop push button functions throughout sequence if Stop Button Detect is en-

abled in the program.

A

Initial

Current

Weld/Peak

Current

Initial

Slope

Final

Slope

Final

Current

Preflow

Postflow

C

B

D

Figure 4-3. Semi-Automatic 3 Mode Sequence