DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #4 (05/28/09) PAGE 16

ASSEMBLY INSTRUCTIONS/OPERATIONS

INSTALLING THE SG24-1000 SAFETY AND DUST

SHIELD ASSEMBLY KIT.

Application: All Models.

Tools Required:

1 each, 5/32 inch Allen wrench.

1 each, 7/16 inch wrench.

2 each, 1/2 inch wrenches.

1 each, flat blade screwdriver.

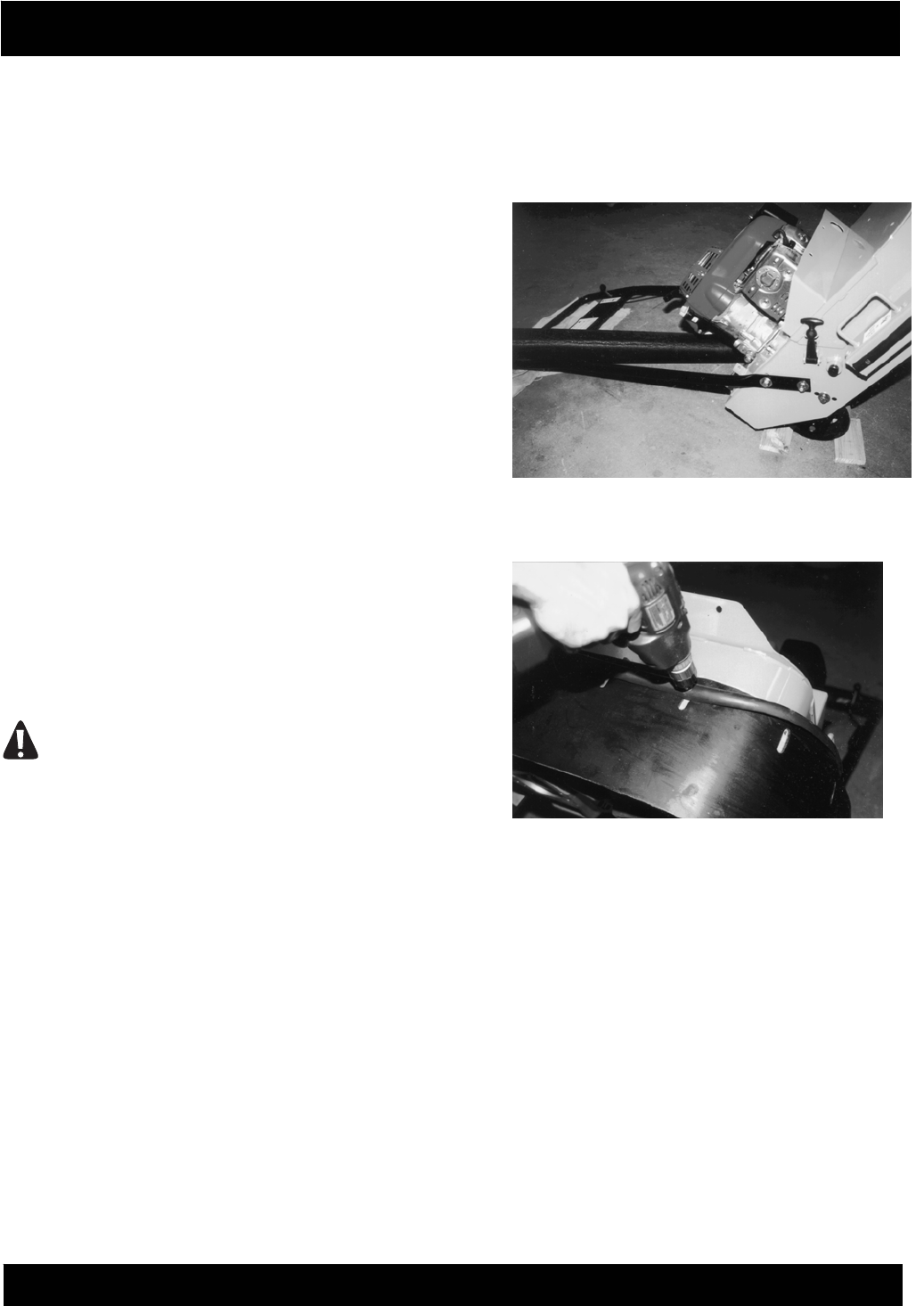

1) If the SURFACE GRINDER is powered by an

engine, disconnect the spark plug wire. If

powered by an electric motor, properly

disconnect the extension cord or SURFACE

GRINDER from the power source.

2) Using the allen wrench, remove the bumper

guard P/N 29018-016 from the machine.

3) Tilt the SURFACE GRINDER back until the

operator handle comes in contact with the

surface. The SURFACE GRINDER may not be

in a stable position in this configuration. To

minimize the possibility of property damage

and/or personnel injury, properly secure an

appropriate weight to the handle for added

stability. Other means can be utilized to support

the frame and provide proper machine sta

bility.

Appropriate wheel chocks are also

recommended. FIGURE 1.

DANGER

EXERCISE EXTREME CAUTION WHEN

WORKING NEAR OR UNDER THE SURFACE

GRINDER WITH THE OPERATOR HANDLE

TILTED BACK IN THE SERVICE POSITION. IF

THE SURFACE GRINDER IS NOT POSITIONED IN

A STABLE CONFIGURATION, WITH ADEQUATE

COUNTERWEIGHT PROPERLY SECURED,

UNEXPECTED MOVEMENT CAN ALLOW THE

SURFACE GRINDER TO FALL BACK TO THE

WORK SURFACE. THE RESULT CAN BE

PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

4) Using the 7/16-inch wrench, install the wrap-

around rubber skirt P/N 29018-88 around the

outside perimeter surrounding the multi-

accessory discs. Secure with cap screws P/N

106499-007 and washers P/N 29018-090. The

original bumper and cap screws can also be

utilized as an alternative attachment method.

The notches in the rubbers skirt are provided as

a means to compensate for multi-accessory

attachment wear (if applicable). Adjust the

location of the rubber skirt to provide the

necessary clearance between it and the work

surface. Improper clearance will accelera

te skirt

wear. FIGURE 2.

FIGURE 1

FIGURE 2

5) Using the 1/2-inch wrenches, the rectangular

rubber skirt P/N 29018-089 is attached to the

middle support member of the main frame.

Proper installation will have the hose attach

fitting that is riveted to the skirt facing the rear of

the machine. The notches in the rubber skirt are

provided as a means to compensate for multi-

accessory attachment wear (if applicable).

Adjust the location of the rubber skirt to provide

the same clearance

as with the wrap-around

rubber skirt P/N 29018-088. The skirt straps PN

29018-092 provide additional support for the

rear skirt assembly. Properly secure with the cap

screws PN 06500-007 and self-locking nuts P/N

08233-005. FIGURE 3.