DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #4 (05/28/09) PAGE 30

ASSEMBLY INSTRUCTIONS/OPERATIONS

Consult applicable OSHA, AGA, CGA, etc.

regulations for the proper transportation flammable

gases.

ADJUSTING THE OPERATOR HANDLE HEIGHT.

Application: All Models.

The DFG Series SURFACE GRINDER incorporates

a handle that can be adjusted to compensate for

variances in operator heights. Three adjustment

heights are provided. Correct handle height can

increase overall machine productivity and reduce

operator fatigue.

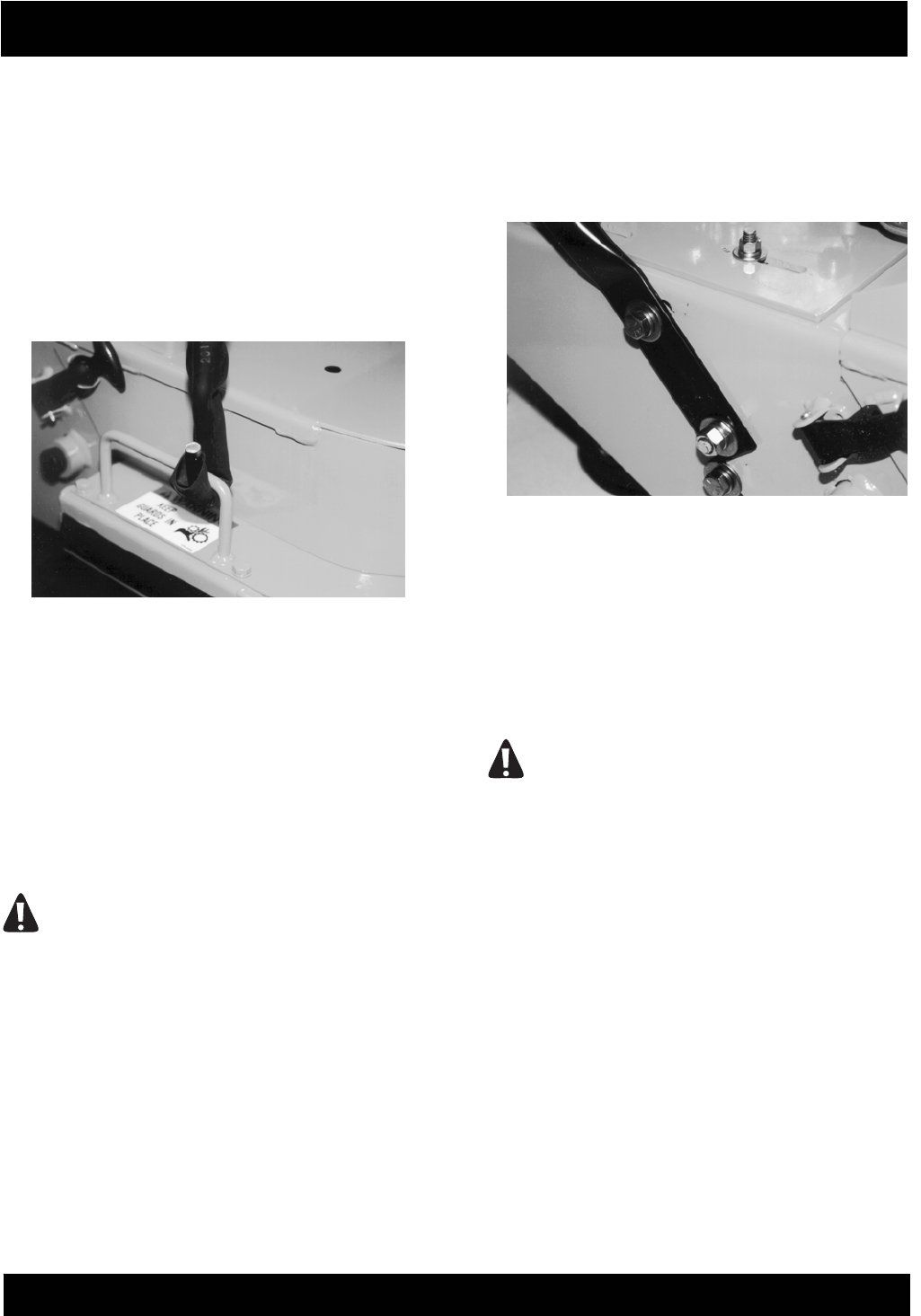

FIGURE 29

Tools Required:

1 each, 3/4 wrench or suitable alternative.

1) Using the wrench, loosen the 1/2-inch hexagon

nuts from the stud assemblies that ret

ain the

handle to the main frame.

2) Using the wrench, remove the 1/2-inch cap

screws that retain the handle in position on the

main frame.

DANGER

EXERCISE EXTREME CAUTION WHEN

REMOVING THE RETAINING CAPSCREWS

FROM THE MAIN FRAME. WHEN THE FINAL

CAPSCREW IS REMOVED, THE HANDLE IS

PROVIDED WITH NO EXTERNAL SUPPORT AND

WILL IMMEDIATELY DROP TO THE FLOOR.

SUCH OCCURRENCE CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

3) Reposition the operator handle in the desired

location that aligns the hole in the handle with

the threaded hole in the main frame. Replace

the 1/2-inch hexagon cap screws and properly

tighten with the wrench. FIGURE 30.

4) Using the wrench, properly tighten the 1/2-inch

hexagon nuts on the stud assemblies that retain

the handle to the main frame.

FIGURE 30

STARTING THE DFG/E SERIES ELECTRICALLY

POWERED SURFACE GRINDER ON THE

JOBSITE.

1) Position the SURFACE GRINDER on a flat and

level surface of firm foundation.

2) Determine that the ON/OFF switch located on

the oper

ator handle is in the OFF position.

DANGER

UNEXPECTED MACHINE START UP CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

3) Select the appropriate operating voltage for the

electric motor. The motor is designed to operate

from a clean, 20 ampere, 115 VAC, 60 Hz

nominal or a clean, 10 ampere, 230 VAC, 60 Hz

nominal power source. A clean power source

refers to the amperage available on the

individual electrical circuit selected. Additional

electrical products already utilizing the same

circuit will reduce the available amperage,

resulting in starting and operational difficulties.

A voltage switch (115/230 VAC, 60 Hz) is

provided on the motor. For added security, the

voltage switch can be locked in position with a

combina

tion or keyed lock with an extended

shank length. FIGURE 31.