DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #4 (05/28/09) PAGE 38

ASSEMBLY INSTRUCTIONS/OPERATIONS

classification is from the American Concrete

Institute. Although the F number system is only a

few years old, it offers these advantages:

a) The system controls both flatness and levelness.

b) There is a standard test method.

c) The system recognizes the statistical nature of

profile testing on random traffic floors.

d) The system is infinitely variable.

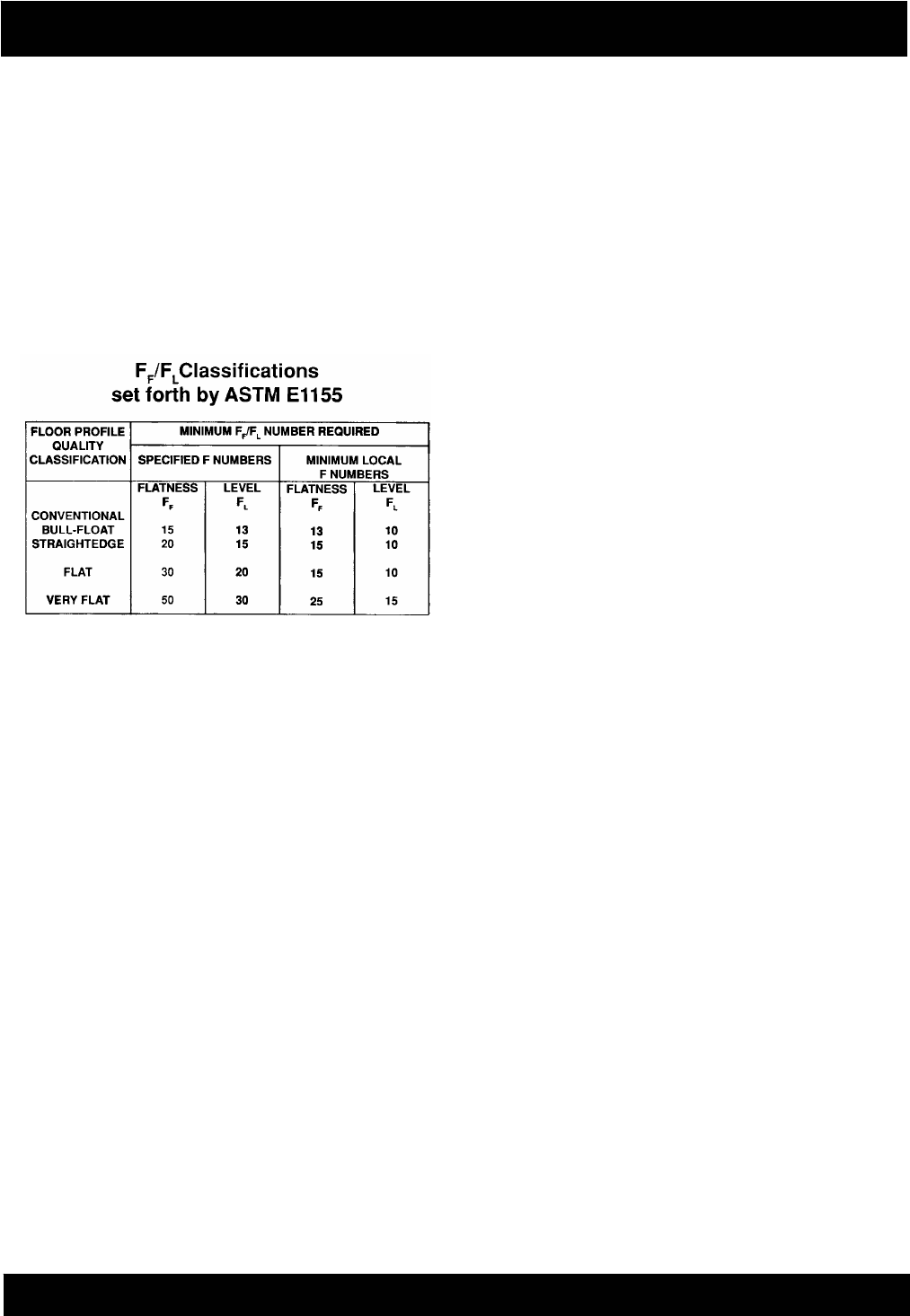

FIGURE 40

One of the major limitations of the F number system

is that it does not control the surface regularity at

joints. Because joints are statistical anomalies, the

stand

ard test method forbids measurements within

24 inches. The designer specifying by F number has

two methods to accommodate the problem. The first

solution is to locate joints at locations where surface

regularity is not important. The second solution is to

design specifications for the joints themselves.

The TR 34 tolerances for defined traffic floors

The TR 34 System divides defined traffic floors into

three categories:

a) Superflat

b) Category 1

c) Category 2

For each category, the TR 34 System specifies limits

for three properties:

Property 1 is the difference in elevation between two

points 12 inches apart, measured in the direction of

vehicle traffic. This is the levelness tolerance.

Property 2 is the difference in slope over 24 inches

measured in the direction of vehicle traffic. This is

the flatness tolerance. It is identical as the 24 inch

curvature utilized in the F number system.

Property 3 is the difference in elevation between

opposite points in the left and right wheel path,

measured perpendicular to the direction of vehicle

traffic. As with Property 1, it is a levelness tolerance.

The TR 34 System specifies different values for

Property 3 depending upon whether the distance

between left and right wheel paths is more or less

than 5 nominal feet

The Superflat category is intended for very narrow

aisle warehouses where the highest standards are

required. Category 1 is suggested for very narrow

aisle warehouses where the vertical lift height is

between 26 and 43 feet. Category 2 is for very

narrow aisle warehouses where the vertical lift

height is under 26 feet and the use of low rise,

automatically controlled vehicles. No matter which

category of surface regularity is specified, it is

accomplished by measuring elevations on 12 inch

centers. This is very simil

ar to an F number survey,

but with an important distinction. In an F number

survey, the elevation profiles are made on the floor

at random. With the TR 34 System, the survey

measurements are made on the actual paths of the

vehicles that will utilize the floor.

Improving the wear resistance of concrete floors

by grinding with the DFG Series SURFACE

GRINDER

Poor wear resistance can often be traced back to a

surface that is weaker than underlying levels of the

pour. This an occurrence can result from bad

finishing techniques, improper curing or early

freezing.

Where surface weakness is a problem, grinding can

be a solution. The process is similar to the early age

technique. The grinding depth is typically 1/16 to 1/8

inch. A large project should not be a

ttempted until a

small test area has proven that the technique will

produce the desired results. Usually only a square

yard of floor is ground with the normal wear tests

performed.

Repair costs can be minimized by grinding only

those floor areas that accommodate traffic. For

example, in a pallet rack warehouse, it may be

necessary to grind only the aisle areas and not

under any of the racks. The grinding process can

adversely affect the surface regularity. Where

specific properties are important, it may be