DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #4 (05/28/09) PAGE 25

ASSEMBLY INSTRUCTIONS/OPERATIONS

CAUTION

Follow all safety precautions for the safety

solvent.

2) Remove the cap screw from the unit. Clean the

newly exposed areas of the insert and SCRAPE-

R-TACH unit with the safety solvent. Clean and

inspect the threaded holes found in older units

for excess wear. New style SCRAPE-R-TACH

units feature a through hole design.

3) Index the insert to expose a new edge. Reinstall

the capscrew and apply a torque value that

properly seats the insert firmly against the body

of the unit.

CAUTION

An insufficient seating torque value will allow the

insert to become loose from the unit body,

resulting in premature component wear and

improper scraping action. An excessive torque

value will strip the threads of the capscrew or

unit body.

4) Determine that the unit body is free to rotate

about the 5/16 inch diameter capscrew that

retains the body to the unit. A body that does not

freely rotate indicates that a material build-up

exists between the rubber mount and retaining

capscrew exits. This build-up must be removed

by disassembling the body from the unit and

cleaning all contact areas with the safety

solvent. FIGURE 20.

The SCRAPE-R-TACH system is designed to be

installed with the edge of the tungsten carbide

inserts facing the direction of rotation. Markings are

provided to indicate proper direction of rotation.

FIGURE 20

CAUTION

Installing the SCRAPE-R-TACH system with the

tungsten carbide inserts facing opposite the

rotation direction will not deliver satisfactory

material removal rates and result in premature

component wear requiring early replacement.

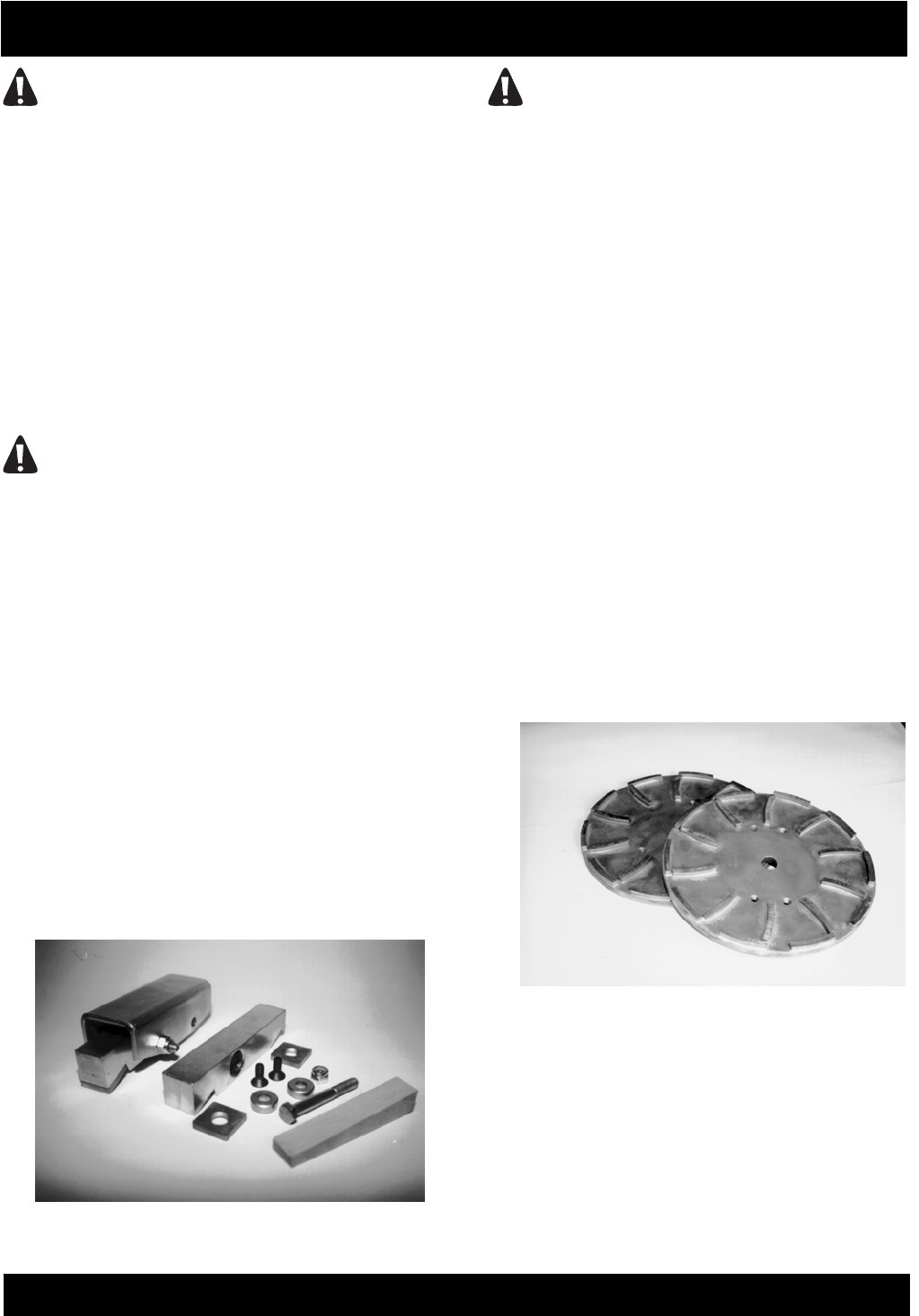

Multi-Segmented, Dry Diamond Disc

Many times increased concrete removal rates can

be achieved with the use of multi-segmented, dry

diamond discs. FIGURE 21. These discs are

designed to operate dry or can also be utilized with

water. If the wet option is chosen, an external source

for providing water must be devised. No provision for

water use is provided with the SURFACE GRINDER.

Typical discs are approximately 10 inch diameter

and feature up to 20 diamond segments that are

welded or brazed to each assembly.

To install the multi-segmented, dry diamond discs,

the standard, aluminum, multi-accessory discs are

first removed from the SURFACE GRINDER. The

diamond discs fasten directly to the gimbal heads

with 3/8 inch di

ameter x 1 inch long Allen head

capscrews. FIGURE 22. The rear wheel assembly is

then placed in the lowest position to compensate for

the thickness variance of the diamond discs.

FIGURE 23.

FIGURE 21