21

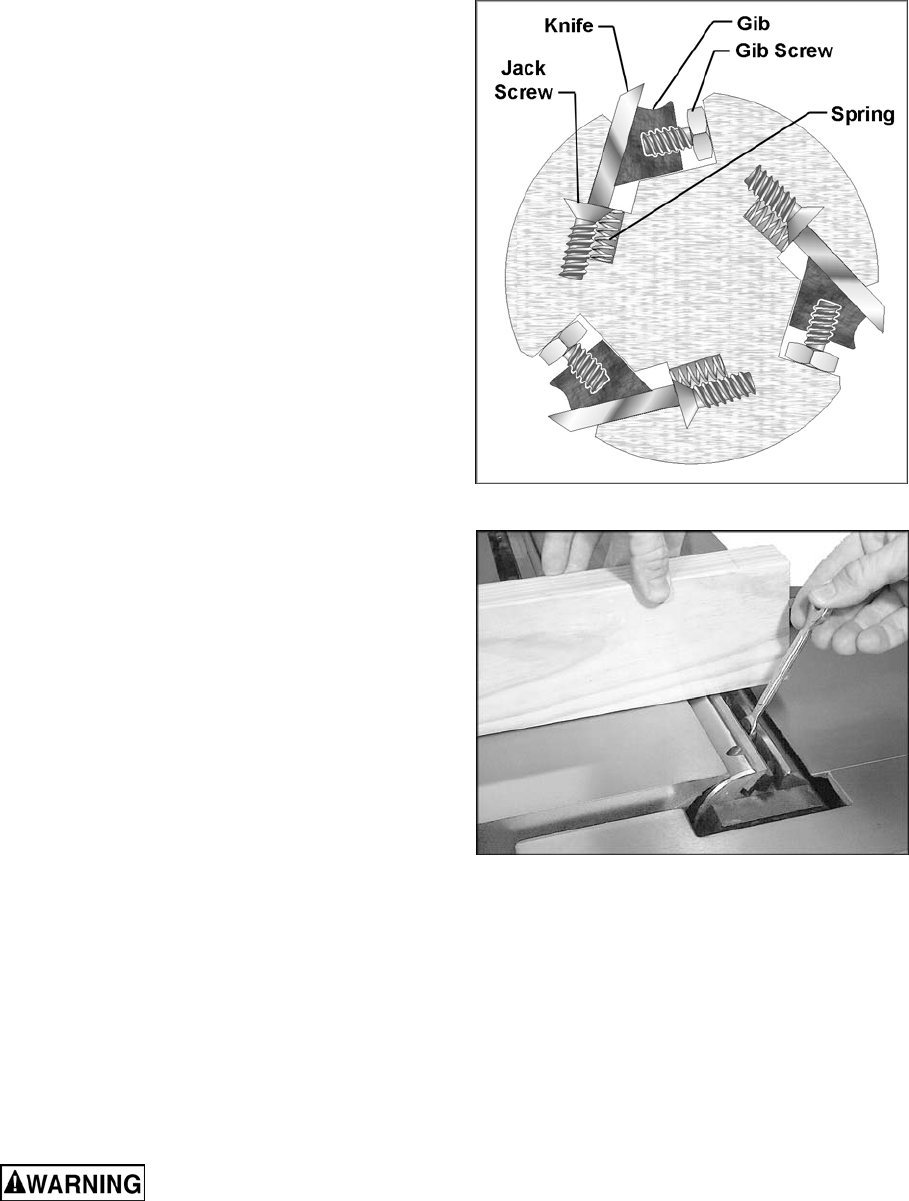

14. Slightly loosen the five gib screws (see

Figure 31) with an 8mm wrench. (NOTE:

The springs below the knife will cause the

knife to rise.)

15. Turn the jack screw(s) with a hex wrench;

clockwise to lower the setting of the knife in

the cutterhead, counterclockwise to raise

the setting of the knife.

16. Use the edge of a board to push the knife

back down so that it is flush against the jack

screws. See Figure 32. Tighten the gib

screws only enough to keep the knife in

position in the cutterhead. Do not fully

tighten.

17. Check the height of the knife again by using

the gauge at front and back of the outfeed

table. Make further adjustments to the jack

screw(s) as needed.

18. Repeat this process for each of the other

two knives in turn. Do not fully tighten gib

screws, only tighten them enough to keep

the knife in position.

19. For best results, knives should be set at

approximately .015" above the cutterhead.

Knife height should not vary more than .002-

.003" across the length of the cutterhead. All

three knives must be set at equal height in

the cutterhead and parallel to the outfeed

table across their length.

20. After all three knives are positioned properly

in the cutterhead and made snug, continue

tightening the gib screws. The gib screws

should be tightened in increments, to

prevent any distortion to the cutterhead or

buckling of knives. Begin tightening the gib

screws a little more on one knife. Start with

the center screw and work your way to the

ends. Do not fully tighten yet.

21. Rotate the cutterhead to the other two

knives in turn. Repeat step 19 for each

knife.

22. The tightening process should continue at

least two more times, each time tightening

the gib screws further on all three knives in

turn. On the third time, the gib screws

should all be firmly tightened.

Before operating the jointer,

make sure all gib screws are firmly

tightened. A loose knife thrown from the

cutterhead can cause severe or fatal injury.

23. After all knife adjustments are completed,

the guards and fence assembly should be

placed back on the machine before

operating.

Figure 31 (straight cutterhead)

Figure 32 (straight cutterhead)