OPERATION

-32-

(Continued Next Page)

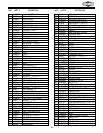

SYMPTOM POSSIBLE REASON HOW TO REMEDY

The sander

runs slow.

The extension cord used is the wrong gauge

and has too much resistance.

The motor is wired incorrectly.

The supply circuit has low voltage and/or high

resistance.

Eliminate the extension cord and move the

sander closer to the wall receptacle.

Contact a qualified electrician if you are

unqualified to do this task: Rewire the junction

box for 110V or 220V as outlined in wiring

diagram and on the motor data plate.

Get a qualified electrician to make sure the

supply circuit used has the load carrying

capacity for your sander and all other machines

using the same circuit.

The belt

tears or

runs off of

the

sander.

The belt tension is too low. As a result, the

belt has run off of the rollers because of

slipping from the sanding load.

The drive roller and/or the idler roller are not

aligned.

The belt is sanding in the wrong direction, it is

worn out, or is defective.

Increase the belt tension to prevent slippage.

DO NOT over tighten the belt tension.

Align the rollers and adjust the vertical belt

tracking.

Install a new belt with the belt rotation arrows

pointing in the correct direction for sander

operation.

The

abrasive

belt has

worn out

quickly.

The workpiece has been pushed too hard

against the sanding belt ruining the belt.

The belt loses the abrasive surface quickly

from moisture, heat, or oil.

The belt is clogged with sanding material.

Replace the belt and decrease how hard you

push on the work piece.

Replace belts that have been improperly stored

in extremely hot or damp places.

Keep belts dressed with belt dressing blocks.

The

sanded

surface is

burnt or

glazed.

The workpiece has been pushed too hard

against the sanding belt.

The sanding belt grit is too fine.

The belt is worn out or it is loaded up with

dust.

Decrease how hard you are pushing and keep

workpiece moving.

Use coarse grit belt and then finish with a fine-

grit sanding belt.

1. Dress the belt.

2. Match the correct belt with the material to

be sanded.

3. Replace worn belts.

(Troubleshooting Continued)